Taking the edge off

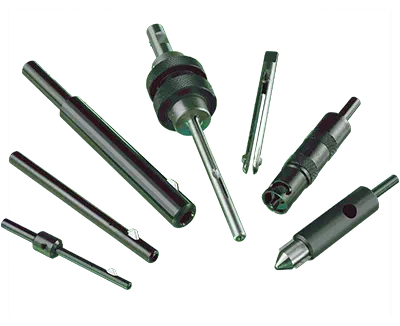

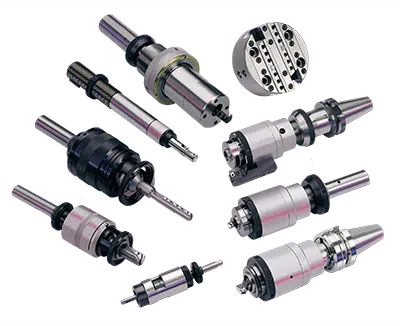

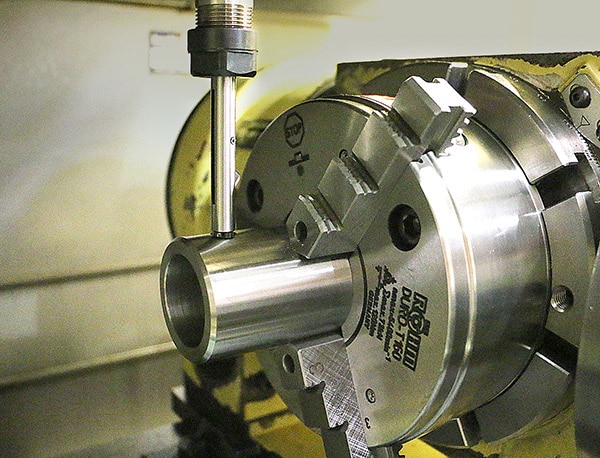

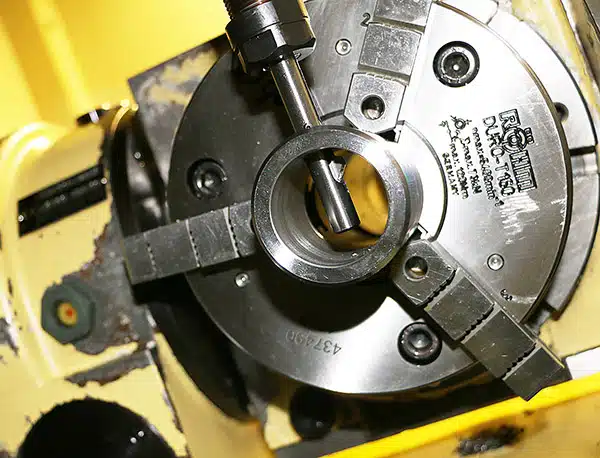

Burraway tools suit a variety of machines from manual to CNC – and can even be used in a hand-drill with excellent results.

They are available in a range of inch and metric sizes ranging from 0.093” (3/32”) to 2 inches or from 2mm to 50mm as standard, and a range of standard sizes for both inch and metric sizes and an assortment of blades are in stock. (See below for tool specifications).

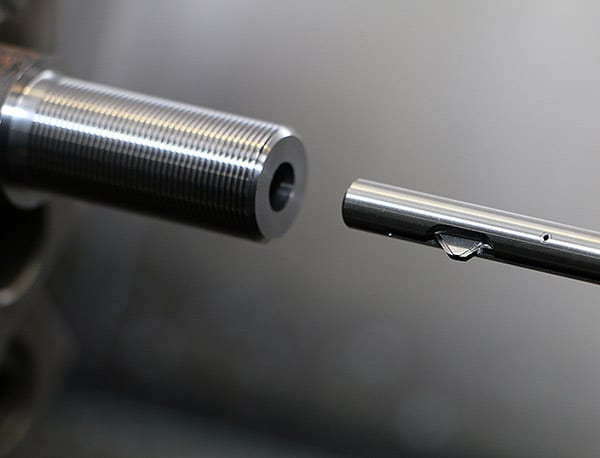

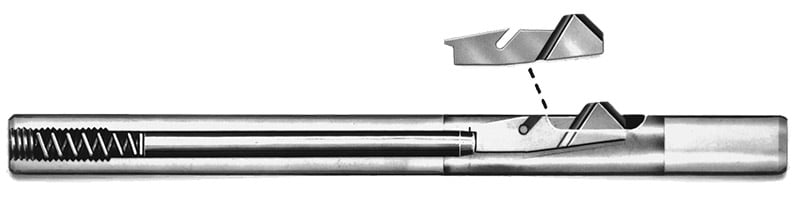

The Burraway tools feature an inexpensive, replaceable cutting blade which adjusts to control the amount of edge break and can be easily replaced within a few seconds. A range of cutting-edge geometry options to suit different materials are offered, and as standard, tools are supplied already fitted with a double acting blade. The crowned and polished top surface of the blade will not mar the inside surface of the hole.

Supporting a simple method for easily adjustable cutting pressure, the corresponding adjustment screws, will match according to the tool as covered by our inch and metric programs.

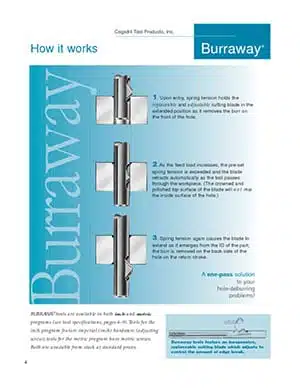

How Burraway tools work:

| 1 | Upon entry, spring tension holds the cutting blade in the extended position as it removes the burr on the front of the hole. |

| 2 | As the feed load increases, the pre-set spring tension is exceeded and the blade retracts automatically as the tool passes through the workpiece. |

| 3 | Spring tension again causes the blade to extend as it emerges from the ID of the part; the burr is removed on the back side of the hole on the return stroke. |

Design features

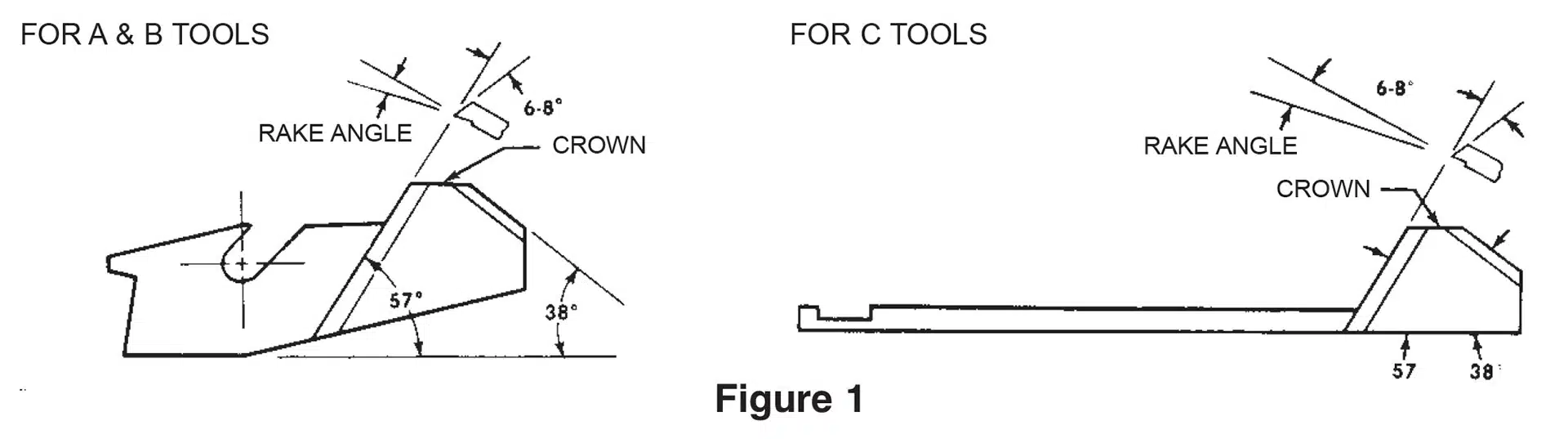

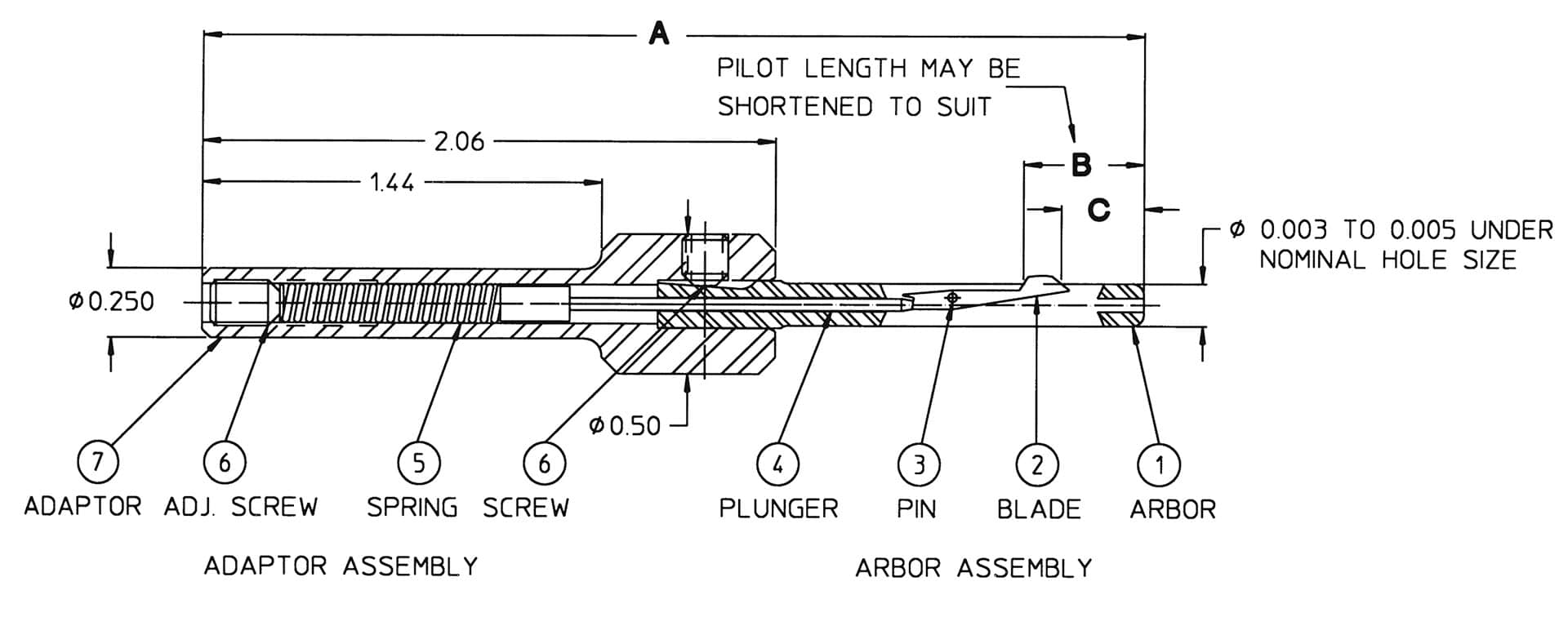

There three types of Burraway tools – Types A, B & C – that correspond to differing diameters. All Burraway tools operate on the same basic principle, but vary slightly in design as determined by tool size:

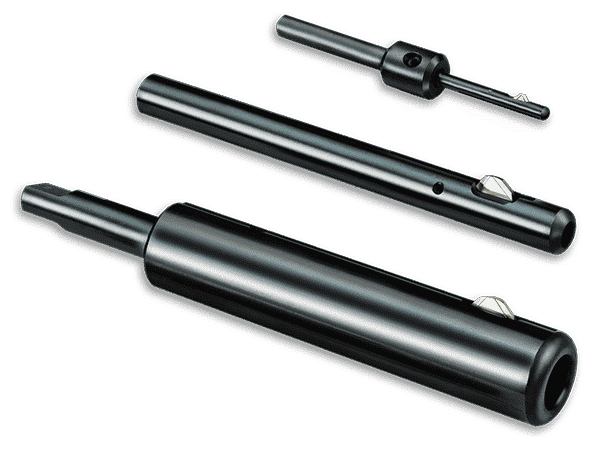

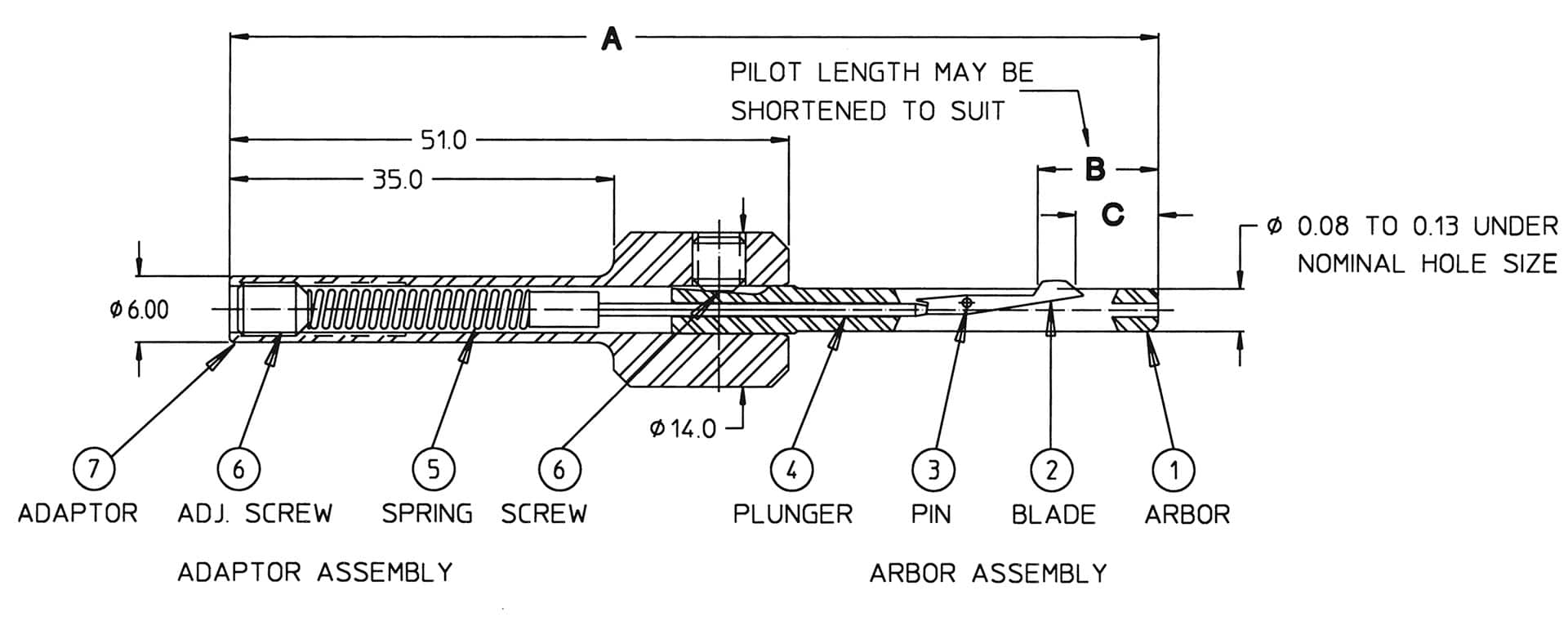

| Type A tools (inch program; for hole sizes from .093 through .203 in.) and Type MA tools (metric program; sizes from 2 to 5mm) are a two-piece construction (arbor assembly and adapter). All Type A and MA arbor assemblies are interchangeable with their respective shank adapters. |

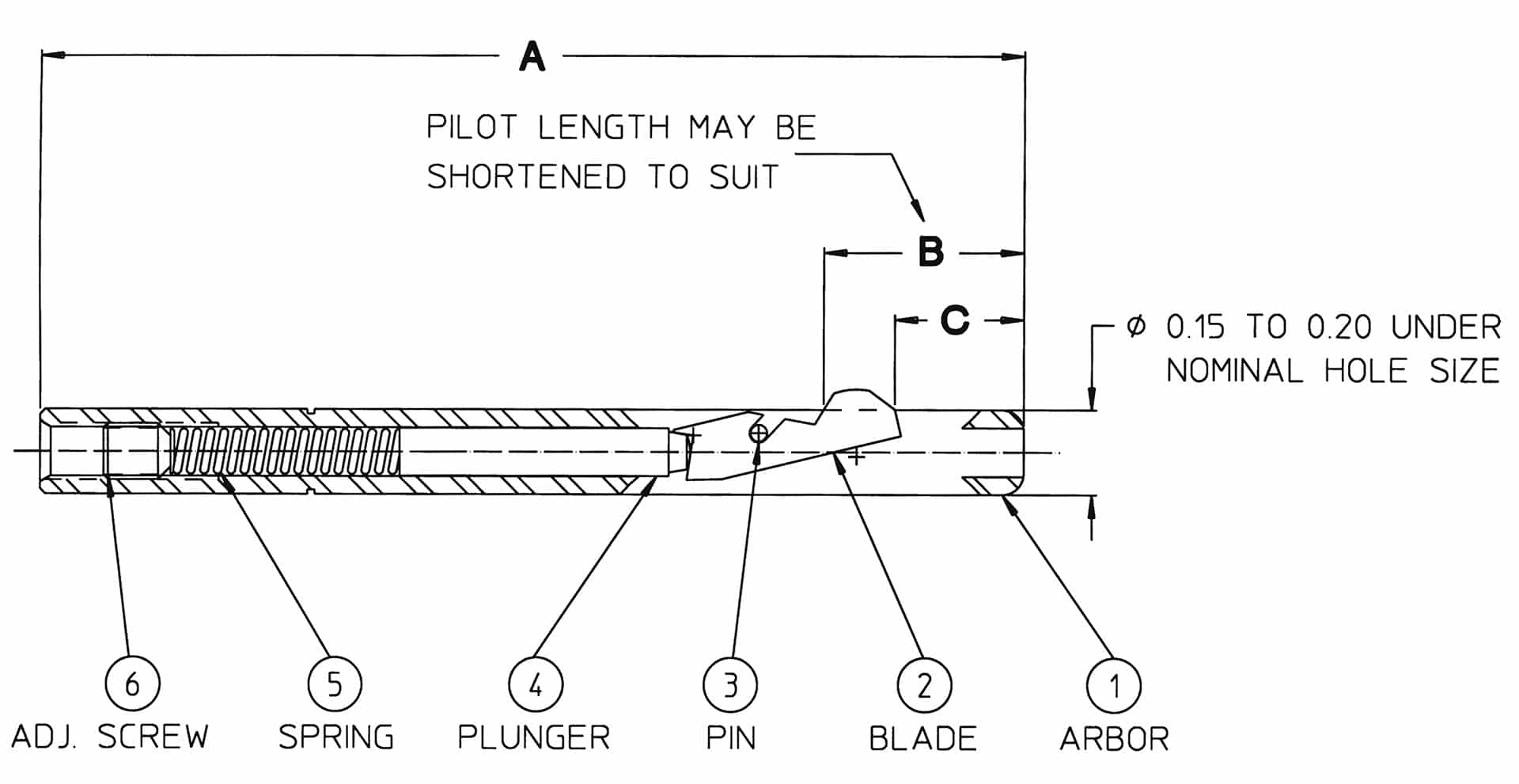

| Type B tools (inch program; for hole sizes from .218 through .750 in.) and Type MB tools (metric program; sizes from 5.5 through 19mm) are a single-piece construction. |

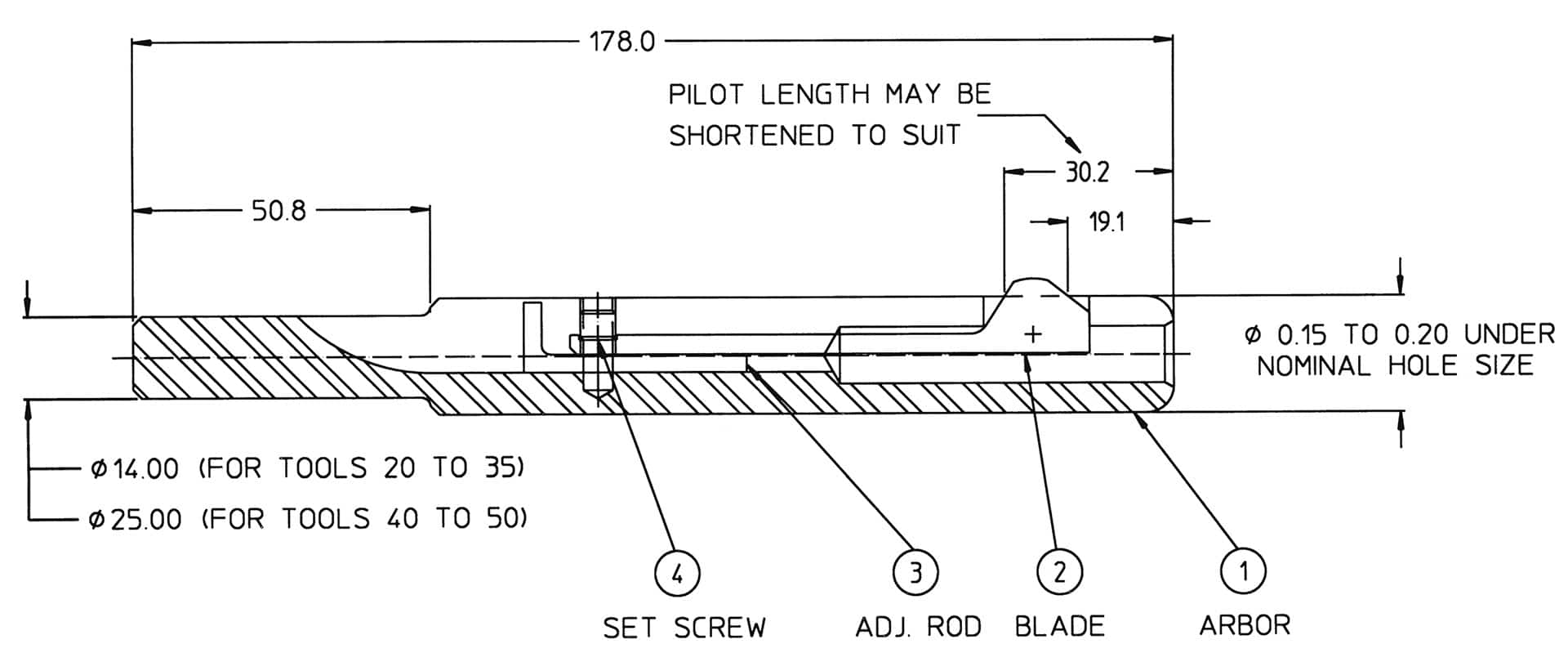

| Type C tools (inch program; for hole sizes from .750 through 2 in.) and Type MC tools (metric program; sizes from 20 through 50mm) are also a single-piece construction. |

A tension adjustment mechanism controls the amount of edge break for consistent results from piece to piece. Types A, MA, B, and MB tools have a tension adjustment screw located in the shank; Types C and MC tools control depth of cut with a tension adjustment rod.

Simple Adjustments. Multiple Options.

A one-pass solution for your hole deburring problems.

We hold a range of inch and metric tools and assortment of blades in stock.

Available for immediate shipping!

A variety of tool designs to meet your needs

Standard Burraway tools are available for both inch and metric hole sizes. Standard drill sizes are available from stock.

Custom tools – larger sizes, altered standards, or special designs – can also be supplied to suit your particular requirements. Please furnish a part print and request a quotation.

Burraway Kit

Our Burraway Kit contains five deburring tools in popular hole sizes:

1/8 in. • 5/32 in. • 3/16 in. • 7/32 in. • 1/4 in.

A replacement blade for each tool is included. The kit is packaged in a durable box. The Burraway Kit enables you to have on hand the solution to burr removal problems for hole sizes most frequently encountered.

PART #: BURRAWAY-KIT

Standard Tool Specifications

Inch Program

Type A

| HOLE SIZE |

DEC. EQUIV |

DIM. A |

DIM. B |

DIM. C |

COMPLETE TOOL # |

BLADE # | ARBOR # | ARBOR ASSEMBLY# |

PLUNGER # | SPRING # | ADAPTER # |

| 3/32 | 0.093 | 3.37 | 0.45 | 0.28 | YA-00938 | YA-DAP-3/32* | YA-00938-D01 | YA-00938-ARB | YA-01250-D04 | YA-1-D05 | YA-AA** |

| 7/64 | 0.109 | 3.37 | 0.45 | 0.28 | YA-01094 | YA-DAP-3/32* | YA-01094-D01 | YA-01094-ARB | YA-01250-D04 | YA-1-D05 | YA-AA** |

| 1/8 | 0.125 | 3.37 | 0.45 | 0.25 | YA-01250 | YA-DAP-1/8 | YA-01250-D01 | YA-01250-ARB | YA-01250-D04 | YA-1-D05 | YA-AA** |

| 9/64 | 0.140 | 3.37 | 0.45 | 0.25 | YA-01406 | YA-DAP-1/8 | YA-01406-D01 | YA-01406-ARB | YA-01250-D04 | YA-1-D05 | YA-AA** |

| 5/32 | 0.156 | 3.37 | 0.45 | 0.25 | YA-01562 | YA-DAP-5/32 | YA-01562-D01 | YA-01562-ARB | YA-01250-D04 | YA-1-D05 | YA-AA** |

| 11/64 | 0.171 | 3.37 | 0.45 | 0.25 | YA-01719 | YA-DAP-5/32 | YA-01719-D01 | YA-01719-ARB | YA-01250-D04 | YA-1-D05 | YA-AA** |

| 3/16 | 0.187 | 4.12 | 0.72 | 0.44 | YA-01875 | YA-DAP-3/16 | YA-01875-D01 | YA-01875-ARB | YA-01250-D04 | YA-1-D05 | YA-AA** |

| 13/64 | 0.203 | 4.12 | 0.72 | 0.44 | YA-02031 | YA-DAP-3/16 | YA-02031-D01 | YA-02031-ARB | YA-01875-D04 | YA-1-D05 | YA-AA** |

All dimensions above are in inches. Intermediate sizes are available upon request.

All tools assembled with a Double-Acting Positive 4° rake (DAP) blade unless otherwise specified.

If you require a different blade, add -M to the complete tool number and specify blade option required.

For more information regarding blade options (including carbide) to suit all materials and applications, please refer to Burraway Blade Data below.

Optional Light Duty (LD) spring available upon request when less tension is required for softer materials.

* We suggest full arbor assembly replacement instead of blade replacement due to the design of the blade in these small sizes.

** Complete with adjustment & lock screws

Type B

| HOLE SIZE |

DEC. EQUIV |

DIM. A |

DIM. B |

DIM. C |

COMPLETE TOOL # |

BLADE # | ARBOR # | PLUNGER # | SPRING # | ADJ. SCREW# |

| 7/32 | 0.218 | 4.50 | 0.87 | 0.56 | YB-02188 | YB-DAP-1 | YB-02188-D01 | YB-02188-D04 | YB-1-D05 | YB-1-D06 |

| 15/64 | 0.234 | 4.50 | 0.87 | 0.56 | YB-02344 | YB-DAP-1 | YB-02344-D01 | YB-02344-D04 | YB-1-D05 | YB-1-D06 |

| 1/4 | 0.250 | 4.50 | 0.87 | 0.56 | YB-02500 | YB-DAP-1 | YB-02500-D01 | YB-02500-D04 | YB-1-D05 | YB-1-D06 |

| 17/64 | 0.265 | 4.50 | 0.87 | 0.56 | YB-02656 | YB-DAP-1 | YB-02656-D01 | YB-02500-D04 | YB-1-D05 | YB-1-D06 |

| 9/32 | 0.281 | 4.50 | 0.87 | 0.56 | YB-02812 | YB-DAP-1 | YB-02812-D01 | YB-02500-D04 | YB-1-D05 | YB-1-D06 |

| 19/64 | 0.296 | 4.50 | 0.96 | 0.68 | YB-02969 | YB-DAP-2 | YB-02969-D01 | YB-03125-D04 | YB-2-D05 | YB-2-D06 |

| 5/16 | 0.312 | 4.50 | 0.96 | 0.68 | YB-03125 | YB-DAP-2 | YB-03125-D01 | YB-03125-D04 | YB-2-D05 | YB-2-D06 |

| 21/64 | 0.328 | 4.50 | 0.96 | 0.68 | YB-03281 | YB-DAP-2 | YB-03281-D01 | YB-03438-D04 | YB-2-D05 | YB-2-D06 |

| 11/32 | 0.343 | 4.50 | 0.96 | 0.68 | YB-03438 | YB-DAP-2 | YB-03438-D01 | YB-03438-D04 | YB-2-D05 | YB-2-D06 |

| 23/64 | 0.359 | 5.00 | 1.00 | 0.68 | YB-03594 | YB-DAP-3 | YB-03594-D01 | YB-03750-D04 | YB-2-D05 | YB-2-D06 |

| 3/8 | 0.375 | 5.00 | 1.00 | 0.68 | YB-03750 | YB-DAP-3 | YB-03750-D01 | YB-03750-D04 | YB-3-D05 | YB-3-D06 |

| 25/64 | 0.390 | 5.00 | 1.00 | 0.68 | YB-03906 | YB-DAP-3 | YB-03906-D01 | YB-04062-D04 | YB-3-D05 | YB-3-D06 |

| 13/32 | 0.406 | 5.00 | 1.00 | 0.68 | YB-04062 | YB-DAP-3 | YB-04062-D01 | YB-04062-D04 | YB-3-D05 | YB-3-D06 |

| 27/64 | 0.421 | 5.50 | 1.09 | 0.72 | YB-04219 | YB-DAP-3-1/2 | YB-04219-D01 | YB-04375-D04 | YB-4-D05 | YB-4-D06 |

| 7/16 | 0.437 | 5.50 | 1.09 | 0.72 | YB-04375 | YB-DAP-3-1/2 | YB-04375-D01 | YB-04375-D04 | YB-4-D05 | YB-4-D06 |

| 29/64 | 0.453 | 5.50 | 1.09 | 0.72 | YB-04531 | YB-DAP-3-1/2 | YB-04531-D01 | YB-04688-D04 | YB-4-D05 | YB-4-D06 |

| 15/32 | 0.468 | 5.50 | 1.09 | 0.72 | YB-04688 | YB-DAP-3-1/2 | YB-04688-D01 | YB-04688-D04 | YB-4-D05 | YB-4-D06 |

| 31/64 | 0.484 | 5.50 | 1.09 | 0.72 | YB-04844 | YB-DAP-3-1/2 | YB-04844-D01 | YB-05000-D04 | YB-4-D05 | YB-4-D06 |

| 1/2 | 0.500 | 5.50 | 1.09 | 0.72 | YB-05000 | YB-DAP-3-1/2 | YB-05000-D01 | YB-05000-D04 | YB-4-D05 | YB-4-D06 |

| 33/64 | 0.515 | 5.50 | 1.09 | 0.72 | YB-05156 | YB-DAP-3-1/2 | YB-05156-D01 | YB-05312-D04 | YB-4-D05 | YB-4-D06 |

| 17/32 | 0.531 | 5.50 | 1.09 | 0.72 | YB-05312 | YB-DAP-3-1/2 | YB-05312-D01 | YB-05312-D04 | YB-4-D05 | YB-4-D06 |

| 35/64 | 0.546 | 6.44 | 1.31 | 0.90 | YB-05469 | YB-DAP-4 | YB-05469-D01 | YB-05625-D04 | YB-5-D05 | YB-5-D06 |

| 9/16 | 0.562 | 6.44 | 1.31 | 0.90 | YB-05625 | YB-DAP-4 | YB-05625-D01 | YB-05625-D04 | YB-5-D05 | YB-5-D06 |

| 37/64 | 0.578 | 6.44 | 1.31 | 0.90 | YB-05781 | YB-DAP-4 | YB-05781-D01 | YB-05938-D04 | YB-5-D05 | YB-5-D06 |

| 19/32 | 0.593 | 6.44 | 1.31 | 0.90 | YB-05938 | YB-DAP-4 | YB-05938-D01 | YB-05938-D04 | YB-5-D05 | YB-5-D06 |

| 39/64 | 0.609 | 6.44 | 1.31 | 0.90 | YB-06094 | YB-DAP-4 | YB-06094-D01 | YB-06250-D04 | YB-5-D05 | YB-5-D06 |

| 5/8 | 0.625 | 6.44 | 1.31 | 0.90 | YB-06250 | YB-DAP-4 | YB-06250-D01 | YB-06250-D04 | YB-5-D05 | YB-5-D06 |

| 41/64 | 0.640 | 6.44 | 1.31 | 0.90 | YB-06406 | YB-DAP-4 | YB-06406-D01 | YB-06562-D04 | YB-5-D05 | YB-5-D06 |

| 21/32 | 0.656 | 6.44 | 1.31 | 0.90 | YB-06562 | YB-DAP-4 | YB-06562-D01 | YB-06562-D04 | YB-5-D05 | YB-5-D06 |

| 43/64 | 0.671 | 6.44 | 1.31 | 0.90 | YB-06719 | YB-DAP-4 | YB-06719-D01 | YB-06875-D04 | YB-5-D05 | YB-5-D06 |

| 11/16 | 0.687 | 6.44 | 1.31 | 0.90 | YB-06875 | YB-DAP-4 | YB-06875-D01 | YB-06875-D04 | YB-5-D05 | YB-5-D06 |

| 3/4 | 0.750 | 6.44 | 1.31 | 0.90 | YB-07500 | YB-DAP-4 | YB-07500-D01 | YB-07500-D04 | YB-5-D05 | YB-5-D06 |

| 7/8 | 0.875 | 6.75 | 1..00 | 1.56 | YB-08750 | YB-DAP-5 | YB-08750-D01 | YB-08750-D04 | YB-7-D05 | YB-7-D06 |

| 1 | 1.00 | 6.75 | 1.00 | 1.56 | YB-10000 | YB-DAP-5 | YB-10000-D01 | YB-10000-D04 | YB-7-D05 | YB-7-D06 |

All dimensions above are in inches. Intermediate sizes are available upon request.

All tools assembled with a Double-Acting Positive 4° rake (DAP) blade unless otherwise specified.

If you require a different blade, add -M to the complete tool number and specify blade option required.

For more information regarding blade options (including carbide) to suit all materials and applications, please refer to Burraway Blade Data below.

Optional Light Duty (LD) spring available upon request when less tension is required for softer materials.

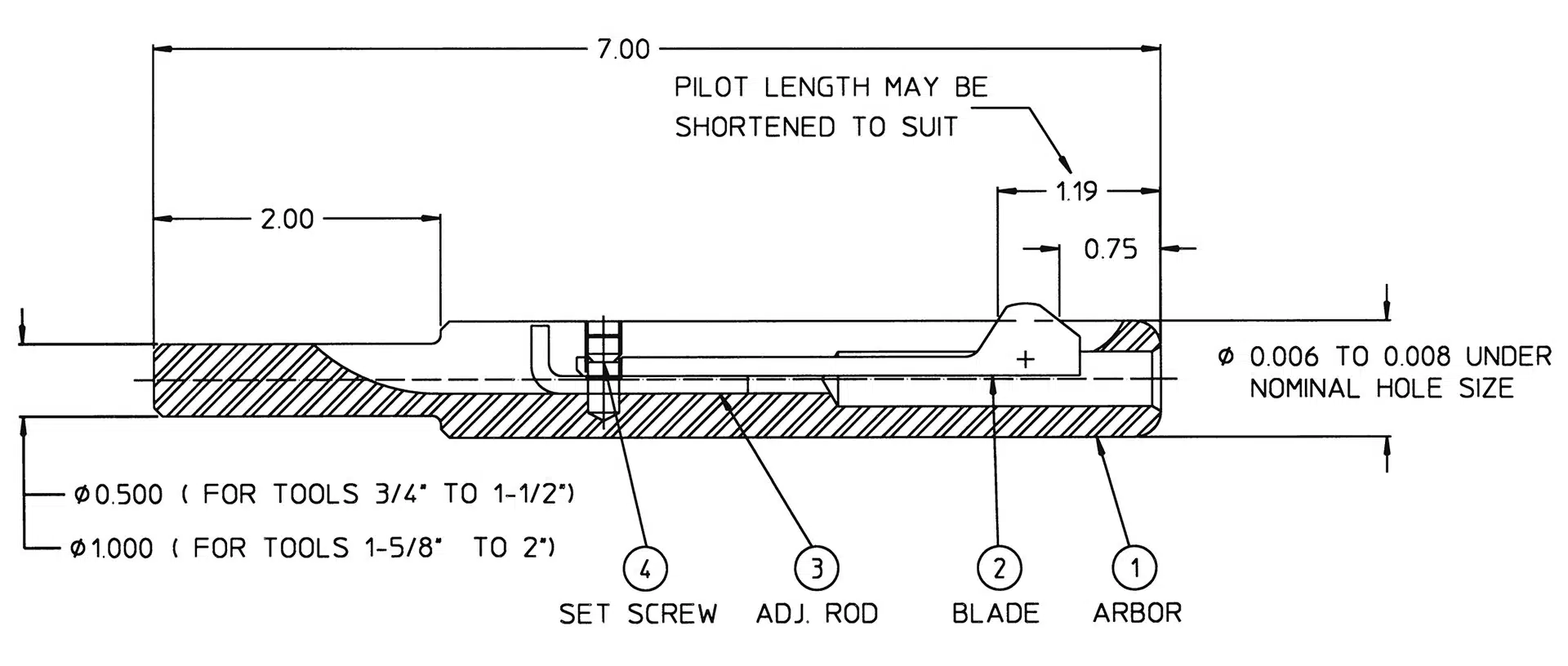

Type C

| HOLE SIZE | DEC. EQUIV | COMPLETE TOOL # | BLADE # | ARBOR # | ADJ. ROD # | ADJ. SCREW # |

| 3/4 | 0.750 | YC-07500 | YC-DAP-110 | YC-07500-D01 | YC-110-D03 | YC-110-D04 |

| 13/16 | 0.812 | YC-08125 | YC-DAP-110 | YC-08125-D01 | YC-110-D03 | YC-110-D04 |

| 7/8 | 0.875 | YC-08750 | YC-DAP-110 | YC-08750-D01 | YC-110-D03 | YC-110-D04 |

| 15/16 | 0.937 | YC-09375 | YC-DAP-110 | YC-09375-D01 | YC-110-D03 | YC-110-D04 |

| 1 | 1.000 | YC-10000 | YC-DAP-110 | YC-10000-D01 | YC-110-D03 | YC-110-D04 |

| 1-1/16 | 1.062 | YC-10625 | YC-DAP-110 | YC-10625-D01 | YC-110-D03 | YC-110-D04 |

| 1-1/8 | 1.125 | YC-11250 | YC-DAP-110 | YC-11250-D01 | YC-110-D03 | YC-110-D04 |

| 1-3/16 | 1.187 | YC-11875 | YC-DAP-110 | YC-11875-D01 | YC-110-D03 | YC-110-D04 |

| 1-1/4 | 1.250 | YC-12500 | YC-DAP-110 | YC-12500-D01 | YC-110-D03 | YC-110-D04 |

| 1-5/16 | 1.312 | YC-13125 | YC-DAP-110 | YC-13125-D01 | YC-110-D03 | YC-110-D04 |

| 1-3/8 | 1.375 | YC-13750 | YC-DAP-110 | YC-13750-D01 | YC-110-D03 | YC-110-D04 |

| 1-1/2 | 1.500 | YC-15000 | YC-DAP-110 | YC-15000-D01 | YC-110-D03 | YC-110-D04 |

| 1-5/8 | 1.625 | YC-16250 | YC-DAP-110 | YC-16250-D01 | YC-110-D03 | YC-110-D04 |

| 1-3/4 | 1.750 | YC-17500 | YC-DAP-110 | YC-17500-D01 | YC-110-D03 | YC-110-D04 |

| 1-7/8 | 1.875 | YC-18750 | YC-DAP-110 | YC-18750-D01 | YC-110-D03 | YC-110-D04 |

| 2 | 2.000 | YC-20000 | YC-DAP-110 | YC-20000-D01 | YC-110-D03 | YC-110-D04 |

All dimensions above are in inches. Intermediate sizes, and tools for diameters larger than shown, are available upon request.

All tools assembled with a Double-Acting Positive 4° rake (DAP) blade unless otherwise specified.

If you require a different blade, add -M to the complete tool number and specify blade option required.

For more information regarding blade options (including carbide) to suit all materials and applications, please refer to Burraway Blade Data below.

Optional Light Duty (LD) spring available upon request when less tension is required for softer materials.

Metric Program

Type MA

| HOLE SIZE |

DIM. A |

DIM. B |

DIM. C |

COMPLETE TOOL # |

BLADE # | ARBOR # | ARBOR ASSEMBLY# |

PLUNGER # | SPRING # | ADAPTER # |

| 2.0 | 84.6 | 11.4 | 6.4 | MYA-2.0 | YA-DAP-2.0MM* | MYA-2.0-D01 | MYA-2.0-ARB | YA-01250-D04 | YA-1-D05 | MYA-AA** |

| 2.3 | 84.6 | 11.4 | 6.4 | MYA-2.3 | YA-DAP-3/32* | MYA-2.3-D01 | MYA-2.3-ARB | YA-01250-D04 | YA-1-D05 | MYA-AA** |

| 2.5 | 84.6 | 11.4 | 6.4 | MYA-2.5 | YA-DAP-3/32* | MYA-2.5-D01 | MYA-2.5-ARB | YA-01250-D04 | YA-1-D05 | MYA-AA** |

| 3.0 | 84.6 | 11.4 | 6.4 | MYA-3.0 | YA-DAP-3.0MM | MYA-3.0-D01 | MYA-3.0-ARB | YA-01250-D04 | YA-1-D05 | MYA-AA** |

| 3.5 | 84.6 | 11.4 | 6.4 | MYA-3.5 | YA-DAP-1/8 | MYA-3.5-D01 | MYA-3.5-ARB | YA-01250-D04 | YA-1-D05 | MYA-AA** |

| 4.0 | 84.6 | 11.4 | 6.4 | MYA-4.0 | YA-DAP-5/32 | MYA-4.0-D01 | MYA-4.0-ARB | YA-01250-D04 | YA-1-D05 | MYA-AA** |

| 4.5 | 103.4 | 18.3 | 11.2 | MYA-4.5 | YA-DAP-3/16 | MYA-4.5-D01 | MYA-4.5-ARB | YA-01875-D04 | YA-1-D05 | MYA-AA** |

| 5.0 | 103.4 | 18.3 | 11.2 | MYA-5.0 | YA-DAP-3/16 | MYA-5.0-D01 | MYA-5.0-ARB | YA-01875-D04 | YA-1-D05 | MYA-AA** |

All dimensions above are in millimetres. Intermediate sizes are available upon request.

All tools assembled with a Double-Acting Positive 4° rake (DAP) blade unless otherwise specified.

If you require a different blade, add -M to the complete tool number and specify blade option required.

For more information regarding blade options (including carbide) to suit all materials and applications, please refer to Burraway Blade Data below.

Optional Light Duty (LD) spring available upon request when less tension is required for softer materials.

* We suggest full arbor assembly replacement instead of blade replacement due to the design of the blade in these small sizes.

** Complete with adjustment & lock screws

Type MB

| HOLE SIZE |

DIM. A |

DIM. B |

DIM. C |

COMPETE TOOL # |

BLADE # | ARBOR # | PLUNGER # | SPRING # | ADJ. SCREW# |

| 5.5 | 114 | 22.1 | 14.2 | MYB-5.5 | YB-DAP-1 | MYB-5.5-D01 | YB-02188-D04 | YB-1-D05 | MYB-1-D06 |

| 6.0 | 114 | 22.1 | 14.2 | MYB-6.0 | YB-DAP-1 | MYB-6.0-D01 | YB-02344-D04 | YB-1-D05 | MYB-1-D06 |

| 6.5 | 114 | 22.1 | 14.2 | MYB-6.5 | YB-DAP-1 | MYB-6.5-D01 | YB-02500-D04 | YB-1-D05 | MYB-1-D06 |

| 7.0 | 114 | 22.1 | 14.2 | MYB-7.0 | YB-DAP-1 | MYB-7.0-D01 | YB-02500-D04 | YB-1-D05 | MYB-1-D06 |

| 7.5 | 114 | 24.4 | 17.3 | MYB-7.5 | YB-DAP-2 | MYB-7.5-D01 | YB-03125-D04 | YB-2-D05 | MYB-2-D06 |

| 8.0 | 114 | 24.4 | 17.3 | MYB-8.0 | YB-DAP-2 | MYB-8.0-D01 | YB-03125-D04 | YB-2-D05 | MYB-2-D06 |

| 8.5 | 114 | 24.4 | 17.3 | MYB-8.5 | YB-DAP-2 | MYB-8.5-D01 | YB-03438-D04 | YB-2-D05 | MYB-2-D06 |

| 9.0 | 127 | 25.4 | 17.3 | MYB-9.0 | YB-DAP-3 | MYB-9.0-D01 | YB-03750-D04 | YB-3-D05 | MYB-3-D06 |

| 9.5 | 127 | 25.4 | 17.3 | MYB-9.5 | YB-DAP-3 | MYB-9.5-D01 | YB-03750-D04 | YB-3-D05 | MYB-3-D06 |

| 10.0 | 127 | 25.4 | 17.3 | MYB-10.0 | YB-DAP-3 | MYB-10.0-D01 | YB-04062-D04 | YB-3-D05 | MYB-3-D06 |

| 10.5 | 140 | 26.2 | 18.3 | MYB-10.5 | YB-DAP-3-1/2 | MYB-10.5-D01 | YB-04375-D04 | YB-4-D05 | MYB-4-D06 |

| 11.0 | 140 | 26.2 | 18.3 | MYB-11.0 | YB-DAP-3-1/2 | MYB-11.0-D01 | YB-04375-D04 | YB-4-D05 | MYB-4-D06 |

| 11.5 | 140 | 26.2 | 18.3 | MYB-11.5 | YB-DAP-3-1/2 | MYB-11.5-D01 | YB-04688-D04 | YB-4-D05 | MYB-4-D06 |

| 12.0 | 140 | 26.2 | 18.3 | MYB-12.0 | YB-DAP-3-1/2 | MYB-12.0-D01 | YB-04688-D04 | YB-4-D05 | MYB-4-D06 |

| 12.5 | 140 | 26.2 | 18.3 | MYB-12.5 | YB-DAP-3-1/2 | MYB-12.5-D01 | YB-05000-D04 | YB-4-D05 | MYB-4-D06 |

| 13.0 | 140 | 26.2 | 18.3 | MYB-13.0 | YB-DAP-3-1/2 | MYB-13.0-D01 | YB-05312-D04 | YB-4-D05 | MYB-4-D06 |

| 13.5 | 140 | 26.2 | 18.3 | MYB-13.5 | YB-DAP-3-1/2 | MYB-13.5-D01 | YB-05312-D04 | YB-4-D05 | MYB-4-D06 |

| 14.0 | 165 | 33.3 | 22.9 | MYB-14.0 | YB-DAP-4 | MYB-14.0-D01 | YB-05625-D04 | YB-5-D05 | MYB-5-D06 |

| 14.5 | 165 | 33.3 | 22.9 | MYB-14.5 | YB-DAP-4 | MYB-14.5-D01 | YB-05938-D04 | YB-5-D05 | MYB-5-D06 |

| 15.0 | 165 | 33.3 | 22.9 | MYB-15.0 | YB-DAP-4 | MYB-15.0-D01 | YB-05938-D04 | YB-5-D05 | MYB-5-D06 |

| 15.5 | 165 | 33.3 | 22.9 | MYB-15.5 | YB-DAP-4 | MYB-15.5-D01 | YB-06250-D04 | YB-5-D05 | MYB-5-D06 |

| 16.0 | 165 | 33.3 | 22.9 | MYB-16.0 | YB-DAP-4 | MYB-16.0-D01 | YB-06562-D04 | YB-5-D05 | MYB-5-D06 |

| 16.5 | 165 | 33.3 | 22.9 | MYB-16.5 | YB-DAP-4 | MYB-16.5-D01 | YB-06562-D04 | YB-5-D05 | MYB-5-D06 |

| 17.0 | 165 | 33.3 | 22.9 | MYB-17.0 | YB-DAP-4 | MYB-17.0-D01 | YB-06875-D04 | YB-5-D05 | MYB-5-D06 |

| 17.5 | 165 | 33.3 | 22.9 | MYB-17.5 | YB-DAP-4 | MYB-17.5-D01 | YB-06875-D04 | YB-5-D05 | MYB-5-D06 |

| 18.0 | 165 | 33.3 | 22.9 | MYB-18.0 | YB-DAP-4 | MYB-18.0-D01 | YB-07187-D04 | YB-5-D05 | MYB-5-D06 |

| 18.5 | 165 | 33.3 | 22.9 | MYB-18.5 | YB-DAP-4 | MYB-18.5-D01 | YB-07500-D04 | YB-5-D05 | MYB-5-D06 |

| 19.0 | 165 | 33.3 | 22.9 | MYB-19.0 | YB-DAP-4 | MYB-19.0-D01 | YB-07500-D04 | YB-5-D05 | MYB-5-D06 |

All dimensions above are in millimetres. Intermediate sizes are available upon request.

All tools assembled with a Double-Acting Positive 4° rake (DAP) blade unless otherwise specified.

If you require a different blade, add -M to the complete tool number and specify blade option required.

For more information regarding blade options (including carbide) to suit all materials and applications, please refer to Burraway Blade Data below.

Optional Light Duty (LD) spring available upon request when less tension is required for softer materials.

Type MC

| HOLE SIZE | COMPLETE TOOL # | BLADE # | ARBOR # | ADJ. ROD # | ADJ. SCREW # |

| 20.0 | MYC-20.0 | YC-DAP-110 | MYC-20.0-D01 | YC-110-D03 | MYC-110-D04 |

| 25.0 | MYC-25.0 | YC-DAP-110 | MYC-25.0-D01 | YC-110-D03 | MYC-110-D04 |

| 30.0 | MYC-30.0 | YC-DAP-110 | MYC-30.0-D01 | YC-110-D03 | MYC-110-D04 |

| 35.0 | MYC-35.0 | YC-DAP-110 | MYC-35.0-D01 | YC-110-D03 | MYC-110-D04 |

| 40.0 | MYC-40.0 | YC-DAP-110 | MYC-40.0-D01 | YC-110-D03 | MYC-110-D04 |

| 45.0 | MYC-45.0 | YC-DAP-110 | MYC-45.0-D01 | YC-110-D03 | MYC-110-D04 |

| 50.0 | MYC-50.0 | YC-DAP-110 | MYC-50.0-D01 | YC-110-D03 | MYC-110-D04 |

All dimensions above are in millimeters. Intermediate sizes, and tools for diameters larger than shown, are available upon request.

All tools assembled with a Double-Acting Positive 4° rake (DAP) blade unless otherwise specified.

If you require a different blade, add -M to the complete tool number and specify blade option required.

For more information regarding blade options (including carbide) to suit all materials and applications, please refer to Burraway Blade Data below.

Optional Light Duty (LD) spring available upon request when less tension is required for softer materials.

Blade Data

Speed / Feed Recommendations and Blade Rake Angle Options

Burraway tools are furnished with Double-Acting High Speed Steel (HSS) blades for burr removal on both the front and back sides of the hole as standard. Blades for front-cutting or back-cutting only are available from stock at no additional charge. Various blade rake angles and spring tension options are available and recommended for deburring specific material types. Carbide-tipped blades are available upon request for nominal hole sizes of 3/16 inch (4.76mm) and larger. HSS with TiN (titanium Nitride) coated blades are also available.

- Positive rake – Ideal for steels and stainless steels

- Negative rake – Ideal for softer materials such as brass or hard plastics

- Neutral rake – Ideal for aluminum

Double-Acting (DA)

For deburring both front and back of holes

Back-Acting (BA)

For deburring back of hole only

Front-Acting (FA)

For deburring front of hole only

| MATERIAL | HSS BLADES | CARBIDE BLADES (0° ONLY) | BLADE STYLE RECOMMENDATION |

||

| SFM | FEED (IPR) | SFM | FEED (IPR) | ||

| Machine Steel | 80-130 | .005-.008 | 240-270 | .005-.008 | 4° Positive Rake Blade (DAP, BAP or FAP) |

| Tool Steel | 40-50 | .005-.008 | 60-120 | .005-.008 | 4° Positive Rake Blade (DAP, BAP or FAP) |

| Steel Forgings | 40-50 | .005-.008 | 60-120 | .005-.008 | 4° Positive Rake Blade (DAP, BAP or FAP) |

| Malleable Iron | 80-90 | .005-.008 | 80-180 | .005-.008 | 4° Positive Rake Blade (DAP, BAP or FAP) |

| Monel Metal | 30-50 | .005-.008 | 80-180 | .005-.008 | 4° Positive Rake Blade (DAP, BAP or FAP) |

| Stainless Steel | 30-50 | .005-.008 | 80-250 | .005-.008 | 4° Positive Rake Blade (DAP, BAP or FAP) |

| Titanium | 25-45 | .005-.008 | 80-250 | .005-.008 | 4° Positive Rake Blade (DAP, BAP or FAP) |

| Cast Iron | 40-60 | .005-.008 | 105-240 | .008-.012 | 0° Neutral Rake Blade (DAZ, BAZ or FAZ) |

| Aluminium | 100-160 | .005-.008 | 250-400 | .008-.012 | 0° Neutral Rake Blade (DAZ, BAZ or FAZ) |

| Brass & Bronze | 100-300 | .005-.010 | 175-300 | .006-.010 | 4° Negative Rake Blade (DAN, BAN or FAN) |

| Plastic / Nylatron | 100-300 | .005-.010 | 175-300 | .006-.010 | 4° Negative Rake Blade (DAN, BAN or FAN) |

| Composites | Not Recommended | 150-200 | .001-.010 | 0° Neutral Rake Blade (DAZ, BAZ or FAZ) | |

All tools assembled with a Double-Acting Positive 4° rake (DAP) blade unless otherwise specified.

Coated blades available upon request. Please contact Cogsdill for pricing and availability.

For Carbide Blades 3MM & 1/8 series and above, specify “C” in place of the three letter blade style (DAP, etc). Example: YA-DAP-1/8 carbide blade is coded “YA-C-1/8”.

Above noted speeds and feeds are basic guidelines and may vary per application

| Feed / Speed Formulas: | Inches | Metric | |||||

| RPM | = | (3.82 X SFM) ÷ Diameter | RPM | = | (318 X M/min) ÷ Diameter | ||

| SFM | = | 0.262 X Diameter X RPM | M/Min | = | (RPM X Diameter) ÷ 318 | ||

| IPM | = | IPR (feed) x RPM (speed) | Mm/Min | = | RPM X Mm/Rev | ||

Blade Replacement

Type A / Type B Tooling

Blade replacement is performed with ease for tools from .118 (3.0mm) and larger. When the tension adjustment screw located at the end of the shank is loosened, the open ended slot allows the blade to slide out freely. The replacement blade can be installed and the adjustment screw retightened back to the desired spring tension.

Type C Tooling

For Type C tooling, loosen the tension adjustment screw located on the arbor OD and slide out both the blade and the tension adjustment rod. Replace in reverse order making sure the adjustment screw is seated securely in the notched area at the blade rear.

YA-00938, YA-01094 / MYA-2.0, MYA-2.3, & MYA-2.5 Tooling

Burraway blades for nominal tool sizes 3/32 & 7/64 (.093 & .109) in our inch program, and blades for 2.0, 2.3, & 2.5 mm tools in our metric program are designed with a pinhole for assembly instead of the slotted blade design. The open-ended slot is not feasible in this size range due to the small blade size. The blade can only be replaced by removing the pivot pin from the arbor, which can cause damage or breakage. We do not recommend blade replacement in these smallest tool sizes. We recommend that the entire arbor assembly be replaced, which consists of the blade, arbor, and plunger.

Tool Adjustment

And Operating Recommendations

Versatile and easy to use

The Burraway can be used on portable power tools and drill motors, drill presses, automatic equipment, CNC machines, or on virtually any type of shop equipment. No special operator skills are required.

Fast and easy adjustment

The amount of stock removed will vary with the hardness of the material. Adjust the set screw in the shank end of the tool to obtain the desired edge break. (Caution: Be careful not to over-adjust; if the spring is compressed to a solid condition, the blade will not be able to retract.) If adjustment fails to produce the desired results, a different blade rake angle or a light-duty spring may be required. Please submit part prints for development of the most efficient tooling for the application.

Blade life and regrinding

Burraway blades generally last about four to ten times longer than the drill used to make the hole. Due to the low cost of replacement blades, most of our customers prefer to replace worn blades with new ones.

However, the blades can be reground and reused. Blades can generally take from five to ten regrinds of .010 inch (0.25mm) each before they must be discarded.

Tool maintenance

The Burraway tool should be inspected periodically for chips, grit, and foreign particles in the slot from which the blade projects. Clean as necessary.

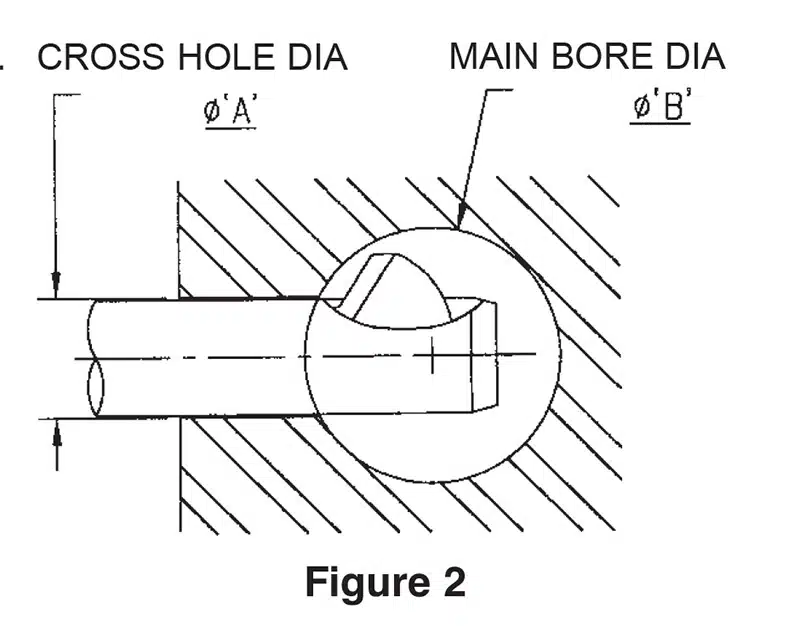

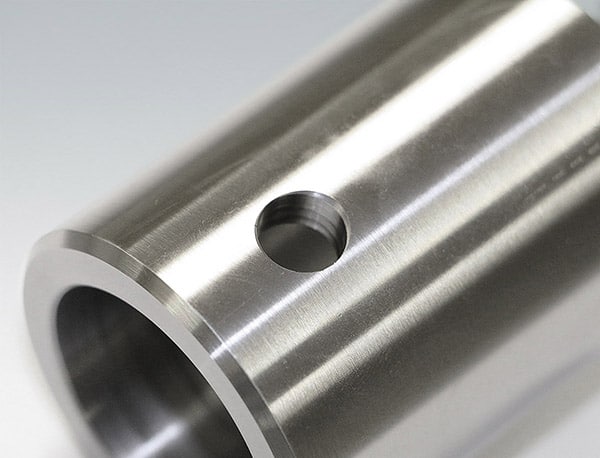

Cross-hole deburring

Burraway tools will tend to cut an elliptical chamfer when deburring a hole drilled through the wall of a larger hole (i.e. the amount of edge break will be inconsistent). If the ratio of the main bore diameter “B” to the cross-hole diameter “A” is less than 3/1 (refer to diagram), the Burraway is not recommended. If the ratio is 3/1 or greater, the standard Burraway tool should be tested and may provide satisfactory results. If not, consider using a tool with a special Burraway blade with a 45° angle, run at speeds of 40-100 RPM; contact our engineering department. If the ratio is questionable, our Burr-Off tool may be considered. While it will tend to cut a greater ellipse, it will also resist breakage on steep side walls. Neither the Burraway nor the Burr-Off is recommended for holes that do not intersect squarely or diametrically.