Aerospace

When your requirements are to achieve maximum strength with minimal weight – crucial in the aerospace industry – we are the proven solution providers.

From take-off to landing and everything in between, Cogsdill is trusted to ensure stability, reliability, efficiency and precision in every aspect of aeronautical engineering.

The sky really is the limit

Extreme demands require unrivalled precision

The design and construction of lighter, more fuel-efficient aircraft are major aerospace industry trends. Cogsdill is developing solutions, utilizing state-of-the-art materials and tool designs for machining operations ranging from simple to complex.

Covering both commercial and military applications, Cogsdill’s commitment to the aerospace industry is unparalleled in providing extreme precision that provides increased reliability, propulsion and stability.

Cogsdill offers many standard and special tooling solutions for machining operations ranging from simple to complex on all aspects of aeronautical engineering.

Complementing our extensive inventory of existing tooling, we are able to custom develop tools to your specific requirements due to our in-house design and manufacturing.

Critical Support

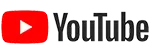

Whether you are machining new or reclaiming existing aircraft components, Cogsdill have a range of tools developed specifically for the aerospace industry. Shefcut special precision reamers, achieve size, accuracy, and location on critical bores in landing gear components. Various features inside landing gear and jet engines, including bottle bores are machined with ease using the Cogsdill MBT (Modular Boring Tool) system.

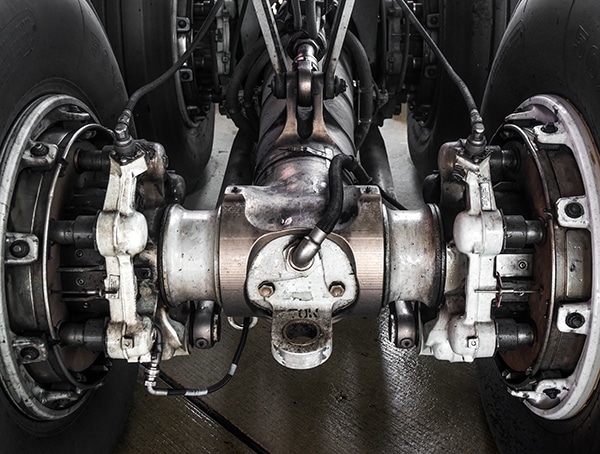

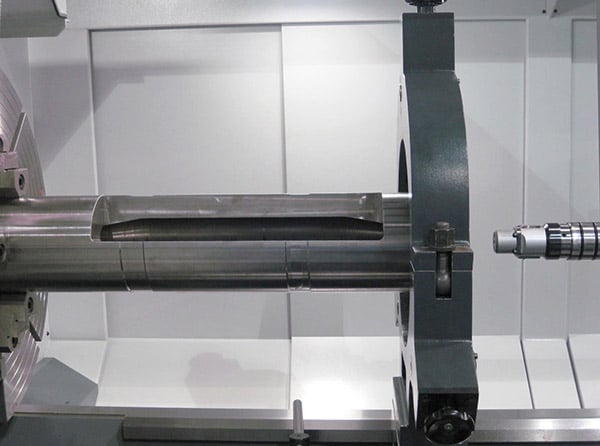

Bottle boring, also known as internal profiling or chamber boring is a special cutting operation where the boring tool expands and contracts within an existing bore to produce a contour inside the workpiece. This enables the manufacturer to machine complex internal shapes, sophisticated bore transitions and undercuts, that reduces the overall weight of critical components without compromising surface integrity. These characteristics are generally too deep or too complicated for single point boring bars. The internal hole profile is larger within the part than at the entry or exit diameters, therefore CNC controls are necessary for coordinating multiple axes simultaneously to create the desired profiles.

The Cogsdill MBT tool is supported with a proven pilot system, either utilizing a rotating O’ring pilot assembly, designed to keep coolant and chips away from the tool body or via coated carbide wear pads, both styles ensuring a vibration free operation, with superior surface finishes. These pads/pilots are designed to suffer the least amount of wear whilst not damaging the base material of the component.

Swarf removal presents a tough challenge when bottle boring. If machining a through hole, the swarf can simply be flushed out of the hole by the workpiece spindle through coolant system. However, in the case of blind holes, and especially with the machining of materials such as nickel based alloys or titanium, the swarf needs to be broken up using high pressure coolant directly onto the insert and through suitable channels.

The Cogsdill Bottle boring tools are designed to use ISO inserts within cartridges or directly fitted into the toolslide. Therefore, depending on the materials to be machined the customer has the flexibitly to use the latest technology and grades of inserts.

The ZX Bottle boring tools are generally used on HBM Machines where the components are too large to be machined on a lathe, however these tools can also be adapted to suit Deep-Hole-Drilling machines, Mill turn machines and Horizontal and Vertical lathes to produce internal extended reach cavities, seat pockets and bottle shaped contours including roughing and finishing operations in one set-up.

Bottle boring. Chamber profiling.

When complex profiles require a vibration-free operation and a superior surface finish.

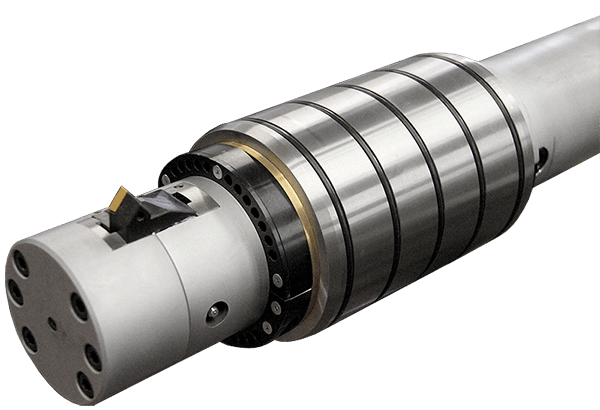

Landing Gear

Aircraft landing gear typically has internal profiling features. Normally made from exotic alloys, the essential requirement for these components is to combine maximum strength with minimal weight. The Cogsdill range of tools are specifically tailored for this demanding application and fully supported through our global network. These tools can be adapted to a range of machines.

- Shefcut precision reamer achieves size, accuracy, and location on critical bores in landing gear components.

- ZX MBT bottle-boring tool for machining internal diameter cavities on landing gear strut and piston assemblies.

Product features:

- High material removal rates.

- Semi-finish and finish with the same tool.

- No depth restriction due to the unique pilot design.

- Extremely fine surface finishes and geometric tolerances are achievable.

- Can be adapted for extreme pressure coolant systems, including Jetbreak®.

- Tools accept a range of industry standard inserts.

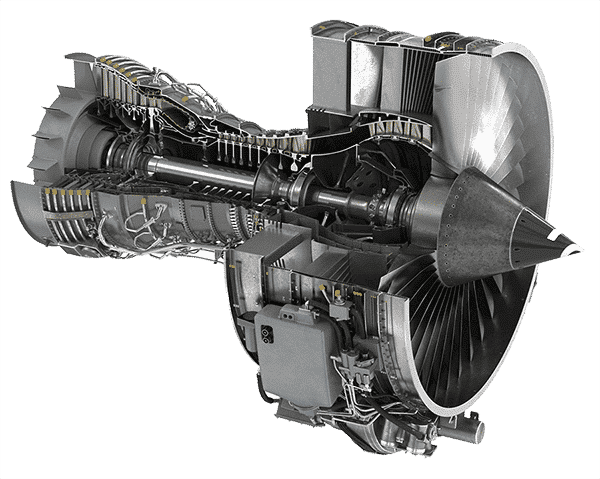

Jet Engines

Aircraft jet engine turbine shafts are typically lightweight, thin-walled components constructed from highly heat-resistant materials which offer their own unique production challenges. Similar to landing gear, the internal features typically consist of complex bottle-bore shapes and contoured features. Maintaining precision over extreme lengths with stringent tolerances is where the Cogsdill range of tooling excel. Our proven design and technology offers repeatability and accuracy within this demanding environment.

- ZX MBT bottle-boring tool for machining bore in jet engine main shaft.

Product features:

- High material removal rates.

- Semi-finish and finish with the same tool.

- No depth restriction due to the unique pilot design.

- Extremely fine surface finishes and geometric tolerances are achievable.

- Can be adapted for extreme pressure coolant systems, including Jetbreak®.

- Tools accept a range of industry standard inserts.

Skins & Other Components

- Burraway tools deburr both sides of rivet holes in one pass, in single or multi-layer materials.

- Nobur JA and JB Recessing tools deburr either one side or both sides of holes in single or multi-layer materials.

- Micro-Limit tool, for precision depth-controlled countersinking in wing skins and other assemblies.

- Shefcut reamers achieve precise size, accuracy, and location in critical bores in components with clevis and linkage joints, actuators and piston bores, landing gear components and in general aircraft fabrications such as hinges.