Countersink with precision

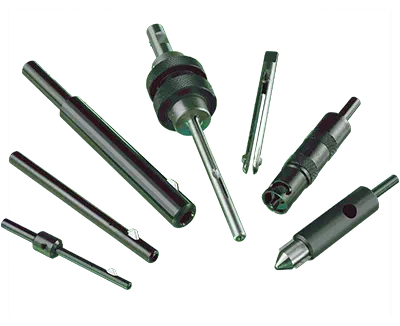

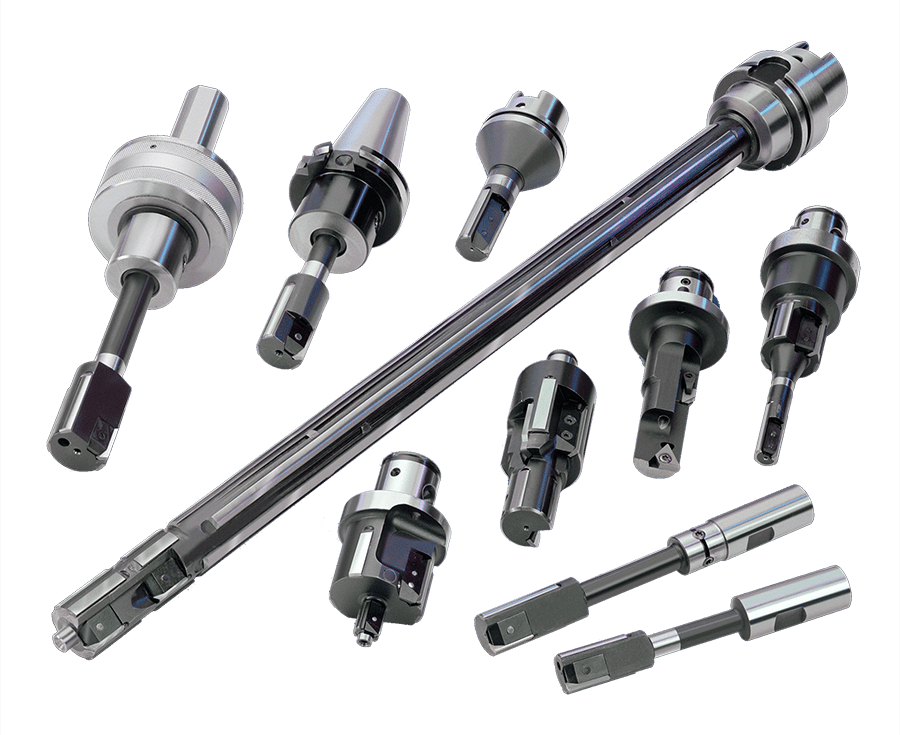

The Micro-Limit is a precision depth-control countersinking tool. The tool consists of a drive with a piloted countersink and a depth control adjustment feature and is suitable for hand held power tools or machine tools.

The Micro-Limit drive is designed and built for rugged production work with repetitive accuracy. The thrust load is taken up on ball bearings through a hardened steel stop collar. The drive shaft rides on needle bearings. This design makes our drive the most durable in the industry and why it is the preferred countersinking tool for high-production requirements, such as rivet hole preparation in aircraft manufacturing.

Three drive models cover a wide range of hole sizes. Adjustment is in increments of .001 inch (.025mm).

How Micro-Limit tools work:

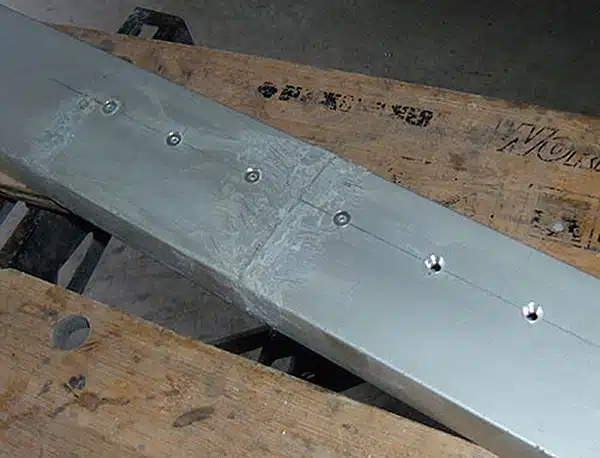

| 1 | The tool is pre-set to the desired depth of cut by simply hand indexing the depth-control collar. |

| 2 | The selected setting is locked in for accurate and consistent results from part to part. |

| 3 | The pilot is engaged in the hole and the stop collar seats on the face of the workpiece. |

| 4 | The tool advances to countersink the hole to the desired depth. |

Countersinks & Pilots

An array of interchangeable countersinks and pilots are available as standard (refer to tool specifications). Countersinks are offered with three standard angles; 82°, 90° and 100°. Special angles and carbide-tipped countersinks are available upon request. Pilots for hole sizes from .125 to .500 inch (3.17 to 12.7mm) are standard; intermediate sizes are available upon request.

Optional Overtravel Feature

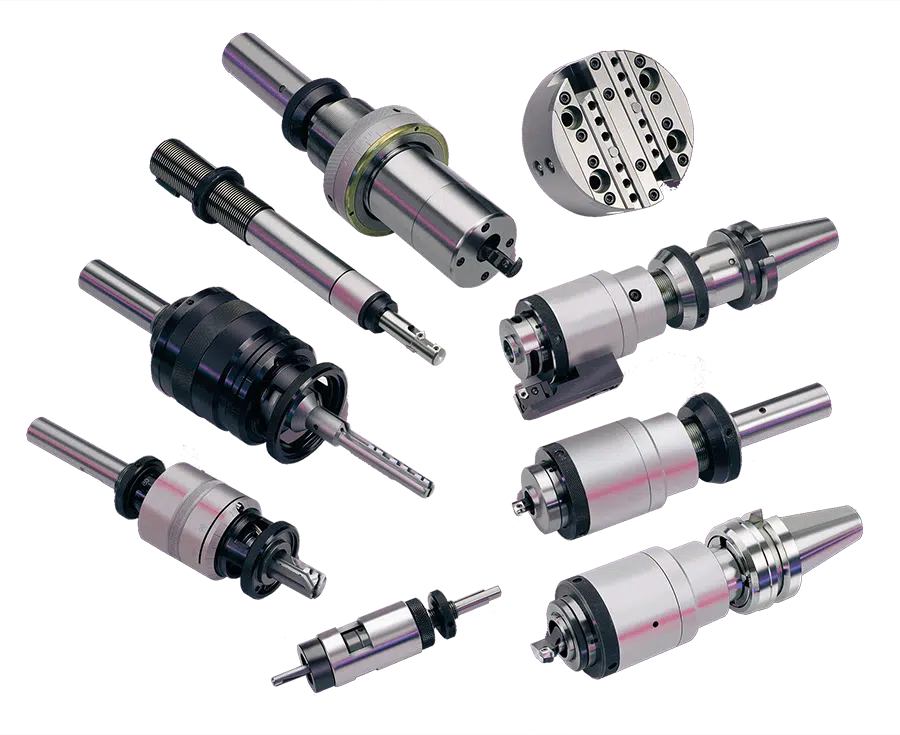

The Micro-Limit is also offered with an overtravel unit built into the standard drive.* Ideally suited to automatic applications, the overtravel feature compensates for variations in part thickness and for overtravel of the machine spindle up to .125 inch (3.17mm). The Micro-Limit with overtravel also simplifies set-up for applications on multiple spindles.

*Available only on #300 and #400 drives.

Micro stop. Piloted countersink.

Precision depth control with accuracy and consistency.

Tool adjustment & operating recommendations

Versatile, easy to use

Use the Micro-Limit on virtually any type of shop equipment. No special operator skills are required.

Quick and easy adjustment

Adjustments are made by hand-indexing the castellated adjustment collar to control the depth of cut. Adjustment is in increments of .001 inch (.025mm).

Speeds and feeds

Use approximately the same speed and feed rate as with a standard HSS drill. However, the greater the depth of cut, the slower the speed required to avoid chatter.

Tool maintenance

For long tool life, the Micro-Limit should be kept free of grit, chips, and foreign matter. The countersink should be replaced when the cutting edges become dull. Loosen the set screw in the side of the countersink to remove the pilot. Unscrew the countersink to remove it from the drive spindle, and replace with a new one.

Custom Designs Available

Altered standards and special designs

are available upon request.