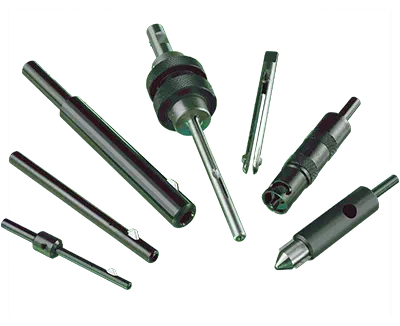

Manually actuated deburring

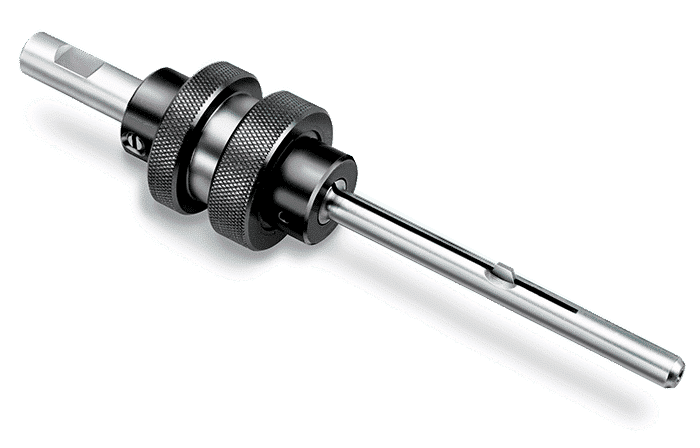

The Nobur Tool is a manually actuated deburring and chamfering tool for use where production requirements are low. The tool is used on multi-walled parts and on intersecting holes. It will remove severe burrs and will produce non-qualified chamfers. The tool body pilots in the hole to be deburred. A quick-action sliding sleeve extends the retractable, double-edged cutting blade to deburr or chamfer the front, back, or both sides of holes, in one pass of the tool.

Since the tool is manually actuated while the spindle continues to run, there is no “on-off” down time.

How Nobur tools work:

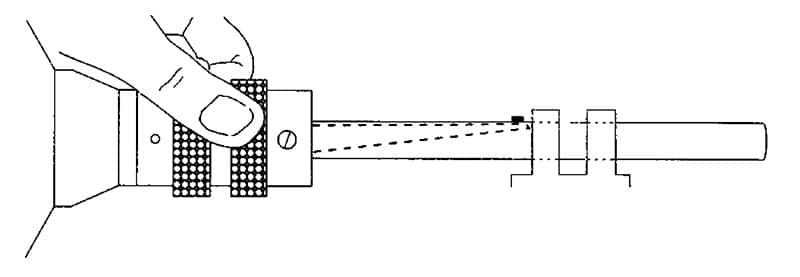

| 1 | The tool should be running in a spindle with the cutting blade in the extended position. The tool is fed into the workpiece. The burr on the outer edge of the first wall is quickly and easily removed. |

| 2 | The sliding sleeve is moved backwards to retract the blade. The workpiece is advanced to such a position that, when the blade is again extended by a forward movement of the sleeve, it will lie between the two walls. The burr on the inner edge of the first wall is then easily removed. |

| 3 | Continued advancement of the tool allows the inner edge of the second wall to be deburred. The sleeve is moved backwards once again to retract the blade so that it can pass through the hole in the second wall. The blade is again extended to deburr the outer edge of the second wall. |

Design Features

The Nobur Tool has a free rolling knurled sleeve, mounted on ball bearings, which allows for fast and easy manual retraction and extension of the blade. The pilot is chrome-plated for long tool life. Standard sizes range from 3/32 to one inch (2.38 to 25.4mm). Work lengths range from 9/16 to 4-3/4 inch (14.28 to 120.65mm).

Blade Options

Three different blade options are available for intersecting hole applications. Blade selection is based upon the ratio of the diameters of the two holes (refer Nobur Guide).

Blade Data

Blades for Nobur tools are manufactured from hardened and precision ground high-speed steel. Three styles are available: standard, and two modified designs (see below for application parameters). For applications other than intersecting holes, the standard blade is used.

Blades for intersecting hole applications

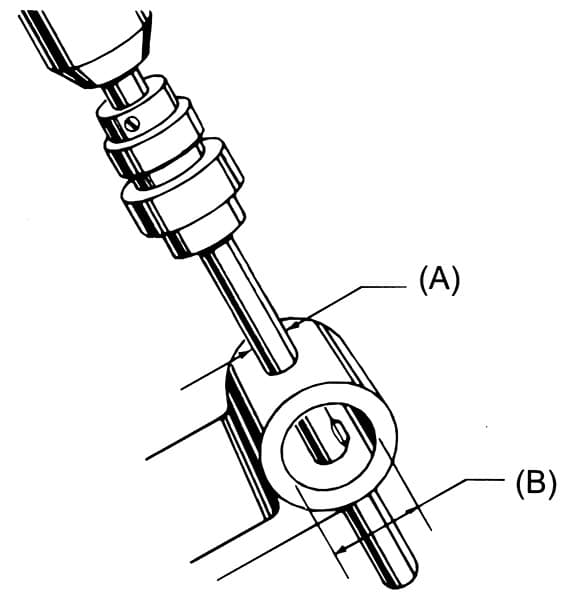

Intersecting holes can sometimes create problems when using the Nobur tool with the standard blade. The following guidelines apply: Standard blades may be used for intersecting hole applications where the larger hole “B” is 12 or more times greater than the smaller hole “A” (refer to figure).

Modified standard blades are available from stock for intersecting hole applications where the following conditions exist:

- Modified blade No. 1 is recommended for intersecting holes where the diameter of the larger hole “B” is between 6 to 12 times greater than the smaller hole “A.”

- Modified blade No. 2 is recommended for intersecting holes where the larger hole “B” is 2-3/4 to 6 times greater than the smaller hole “A.” (Operating speeds from 25-75 RPM are also recommended for applications within this range of intersecting hole diameter ratios.)

Note: The Nobur tool is not recommended for lower ratios of diameter or for holes which do not intersect squarely.

Tool adjustment & operating recommendations

Tool operation

Nobur Tools can be run on a drill press, lathe, or any rotating spindle.

Material Types

Nobur tools can be applied on steel, stainless steel, brass, bronze, aluminum, or virtually any ferrous or non-ferrous materials.

Speeds

Low operating speeds are recommended for the Nobur tool. A range of 50 to 650 RPM is sug-gested, with slower speeds required for larger tool sizes and heavy parts.

High spindle speeds will not result in faster production, since only three or four revolutions of the tool are required to remove the burr. High spindle speeds are likely to dull the blade edge, create excessive wear on the pilot shaft, or cause chatter. The part should be supported as necessary.