Flat on your face

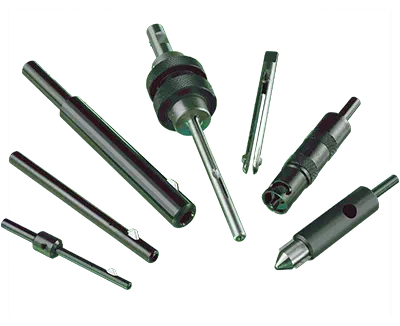

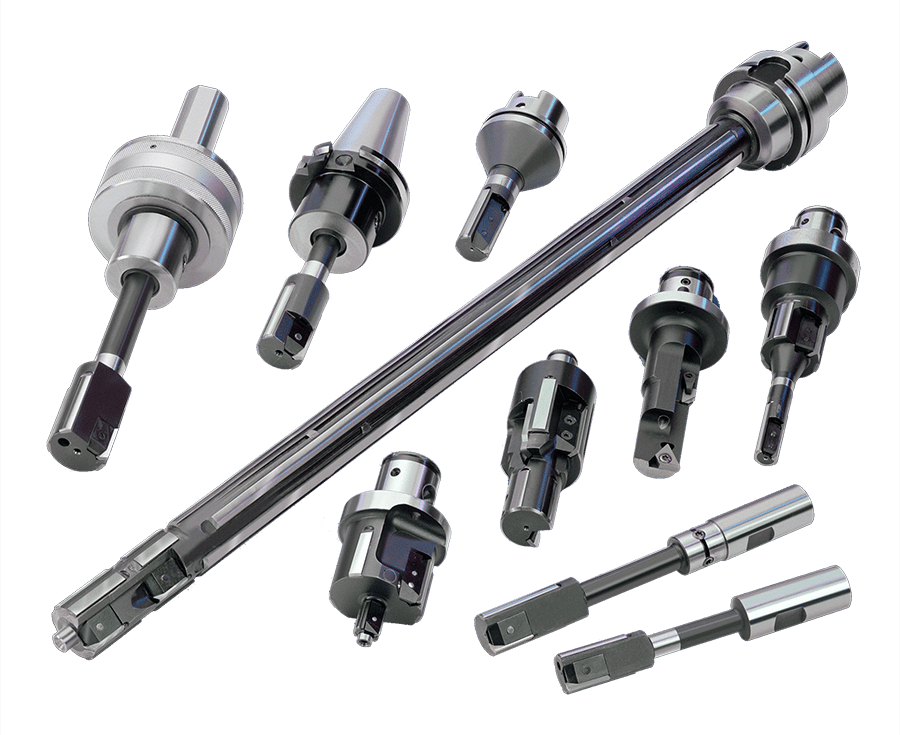

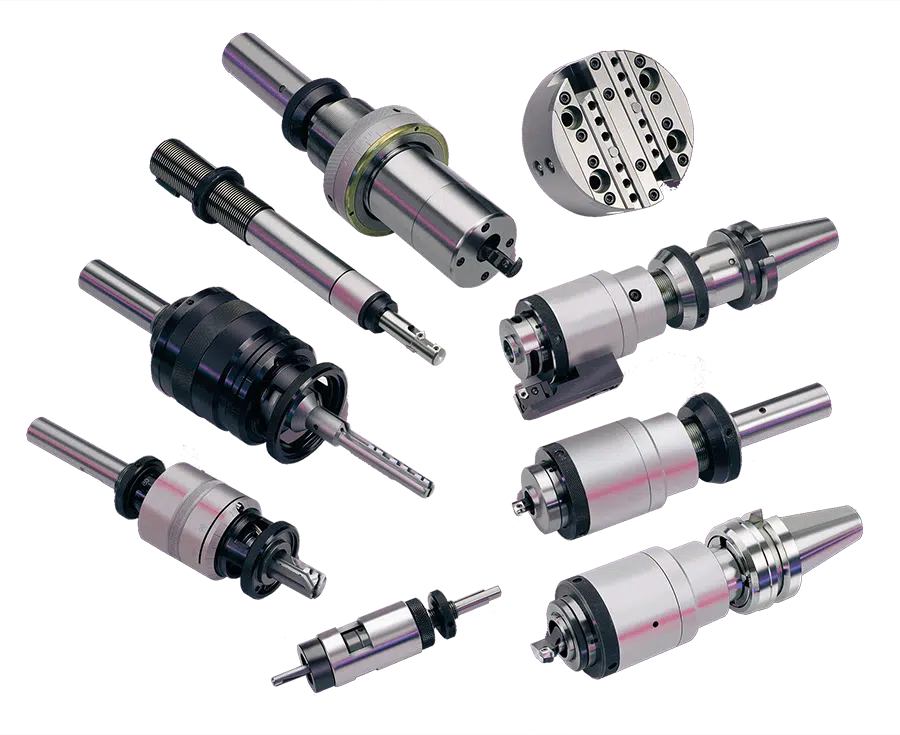

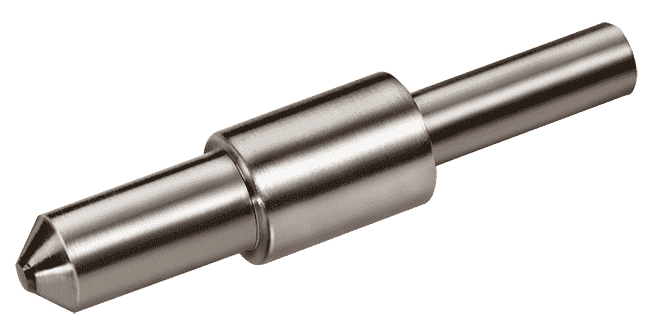

A new addition to the Cogsdill Burnishing lineup is the Diamond Burnish Face Mill Tool (DBFM) for burnishing flat faces to achieve superior surface finishes.

Using Cogsdill proven diamond insert geometry, our premium range of burnishing tools can achieve low RA surface finishes, by cold flowing the peaks into the valleys in one pass – achieving results not attainable from any other metal removal process.

Simple and efficient, Cogsdill DBFM tools are designed to produce mirror-like finishes on any surface; from carbon steels to tool steels, cast iron to alloys, and most ferrous and non-ferrous metals.

Set up and operation is relatively simple, no special operator skills are required.

All tools are supplied with through coolant capability but while the tool must be used with coolant, no special coolant is required. Straight oils, soluble oils, and synthetic coolants can be used to provide the necessary lubrication.

DBFM Tool Operation

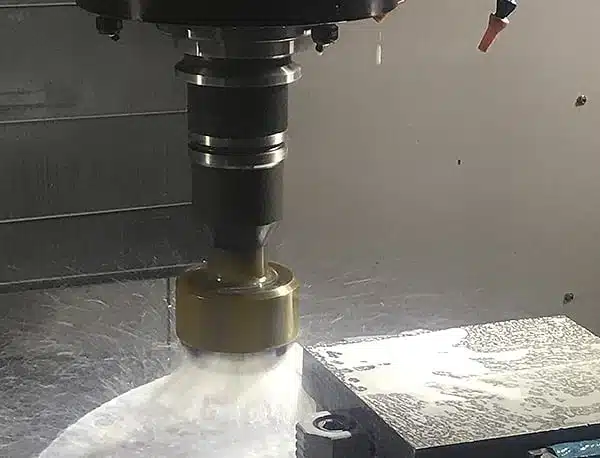

| 1 | The Cogsdill Diamond Burnish Face Mill tool is mounted to a standard milling arbor which fits into the spindle of any machining centre. |

| 2 | The diamond burnishing inserts are brought into contact with the workpiece perpendicular to the surface being finished. |

| 3 | The tool is then fed into the workpiece an additional .002 to .004 inch (.05 to .10 mm) to allow the diamond inserts to disengage from the stops in the holders. |

| 4 | The internal springs, with their adjustable preloads, force the multiple diamonds against the workpiece. |

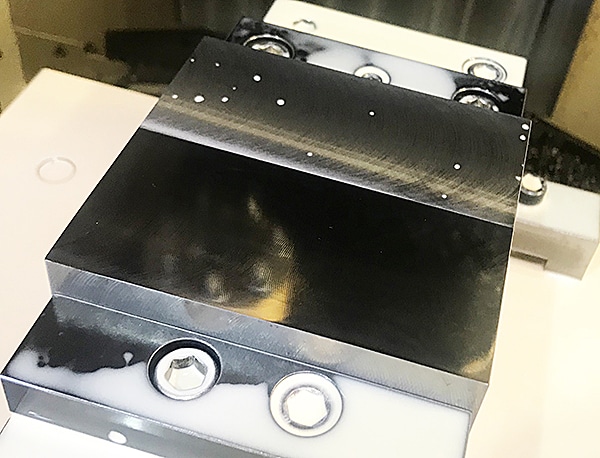

| 5 | The continually rotating tool is then fed along the surface of the workpiece which produces a mirror-like finish. |

| 6 | Although the tools are supplied with pre-loaded spring pressures, they can be adjusted if required, depending upon material specification. |

Diamond Burnish Face Mill Tools are versatile

- Designed to fit in your CNC machining center, with a common interface to suit industry-standard milling arbors.

- The tools can be used on both large and small areas, and are ideal for short production runs. The Diamond Burnish Face Mill Tool can produce quality finishes on interrupted surfaces, such as a face of a flange having a series of bolt holes or a keyway.

- The tools are supplied pre-loaded, but the spring pressure can be adjusted to ensure consistent pressure on the face of the component, assuring repeatability from part to part.

- Spare diamond inserts are easily replaced and available from stock. The premium quality and replaceable diamond burnishing insert is polished and contoured to provide superior finishes and long tool life.

- Although the diamond nibs are qualified, Cogsdill recommended replacing nibs as a set.

Flat Out. Mirror Finish.

Work harden to a superior finish in one pass. Burnish flat surfaces effortlessly.

A standard range of tools are available.

Please contact us for delivery.

Standard Tool Specifications

| Tool No | Size (mm) | A | B | C | No. of Nibs |

| DBFM-63 | 63 | 89 | 90 | 27* | 5** |

| DBFM-80 | 80 | 89 | 110 | 32* | 7** |

| DBFM-100 | 100 | 89 | 130 | 40* | 7** |

| DBFM-125 | 125 | 89 | 155 | 40* | 9** |

*Standard Face Mill Arbor Size

** Replacement Nib Code DB1-040Q

Test Results

EN32

| Burnishing Parameters | |

| Speed | 1000 RPM |

| Feed | 0.07 mm per diamond Insert |

| Interference | 0.1 mm |

| Milled Finish | 1.0 Ra |

| Burnished Finish | 0.01 Ra |

Aluminum

| Burnishing Parameters | |

| Speed | 1000 RPM |

| Feed | 0.07 mm per diamond Insert |

| Interference | 0.1 mm |

| Milled Finish | 0.9 Ra |

| Burnished Finish | 0.03 Ra |

410 and 316 Stainless

| Burnishing Parameters | |

| Speed | 900 RPM |

| Feed | 0.36 mm per diamond Insert |

| Interference | 0.06 mm |

| Milled Finish | 0.8 Ra |

| Burnished Finish | <0.1 Ra |

Iron Remko TS14333

| Burnishing Parameters | |

| Speed | 900 RPM |

| Feed | 0.10 mm per diamond Insert |

| Interference | 0.06 mm |

| Milled Finish | 0.4 Ra |

| Burnished Finish | <0.03 Ra |

Pure Copper

| Burnishing Parameters | |

| Speed | 1,000 RPM |

| Feed | 0.04 mm per diamond Insert |

| Interference | 0.08 mm |

| Milled Finish | 0.3 Ra |

| Burnished Finish | <0.01 Ra |

Recommended starting point: 150 m/min & 0.1mm per diamond (500 SFM & 0.004 inch per diamond)