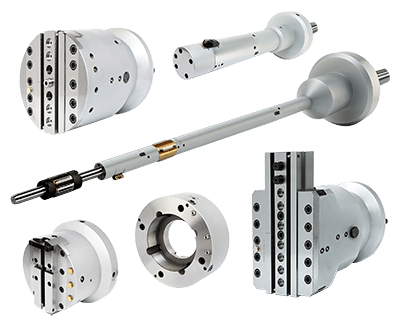

Introducing the most anticipated addition to the Cogsdill’s burnishing portfolio

Anti-Vibration Diamond Burnishing Tools (AVDBT)

Combining Cogsdill’s proven diamond insert geometry with the latest auto-tuning, mass dampening, anti-vibration technology – AVDBT offers incredibly low Ra surface finishing for both external diameters and internal bores at depths up to a staggering 15xD!

Introducing the most anticipated addition to the Cogsdill’s burnishing portfolio

Anti-Vibration Diamond Burnishing Tools (AVDBT)

Combining Cogsdill’s proven diamond insert geometry with the latest auto-tuning, mass dampening, anti-vibration technology – AVDBT offers incredibly low Ra surface finishing for both external diameters and internal bores at depths up to a staggering 15xD!

Typically, with conventional single point boring and burnishing, surface finish deterioration can arise when machining applications over 4xD due to increased vibration and regenerative tool chatter. This becomes more problematic when working with even higher overhangs.

Trying to stabilise the surface finish usually involves a lower cutting speed, reduced depth of cut, or increased feed per revolution. All adding to higher production costs or compromising on quality.

Typically, with conventional single point boring and burnishing, surface finish deterioration can arise when machining applications over 4xD due to increased vibration and regenerative tool chatter. This becomes more problematic when working with even higher overhangs.

Trying to stabilise the surface finish usually involves a lower cutting speed, reduced depth of cut, or increased feed per revolution. All adding to higher production costs or compromising on quality.

GAME CHANGING

Cogsdill’s new range of tooling with advanced Anti-Vibration technology is a total game changer. Not only does it auto-adjust to the vibrations that are causing the tool chatter during initial machining, but with the addition of our interchangeable diamond burnishing head, you can now pre-op and finish from one tool. Achieve unrivalled surface finishes in both internal and external applications.

GAME CHANGING

Cogsdill’s new range of tooling with advanced Anti-Vibration technology is a total game changer. Not only does it auto-adjust to the vibrations that are causing the tool chatter during initial machining, but with the addition of our interchangeable diamond burnishing head, you can now pre-op and finish from one tool. Achieve unrivalled surface finishes in both internal and external applications.

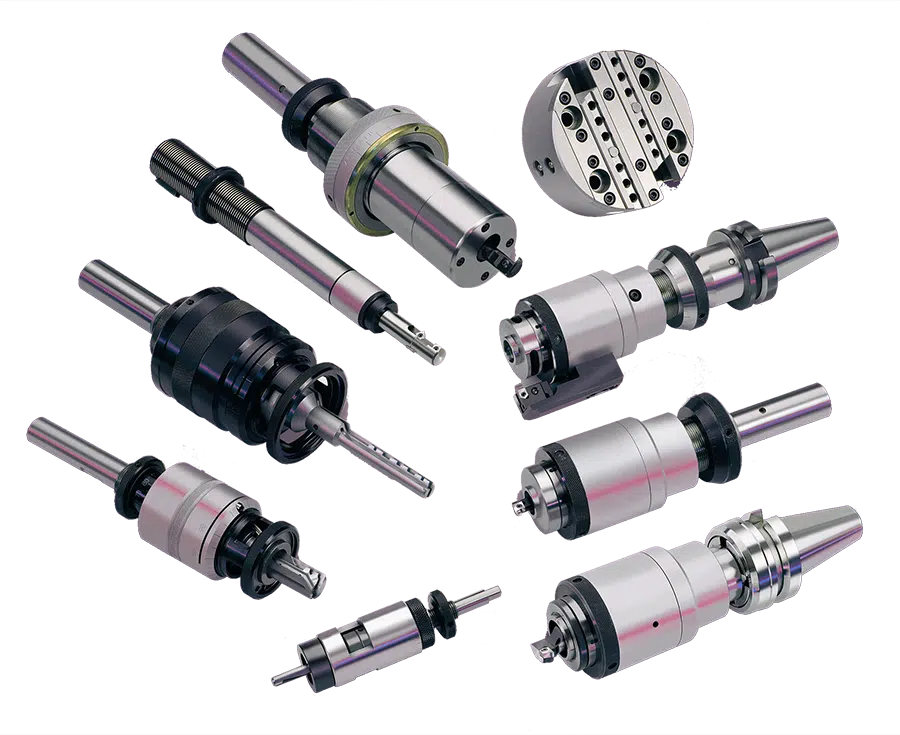

GOOD(BYE) VIBRATIONS

GOOD(BYE) VIBRATIONS

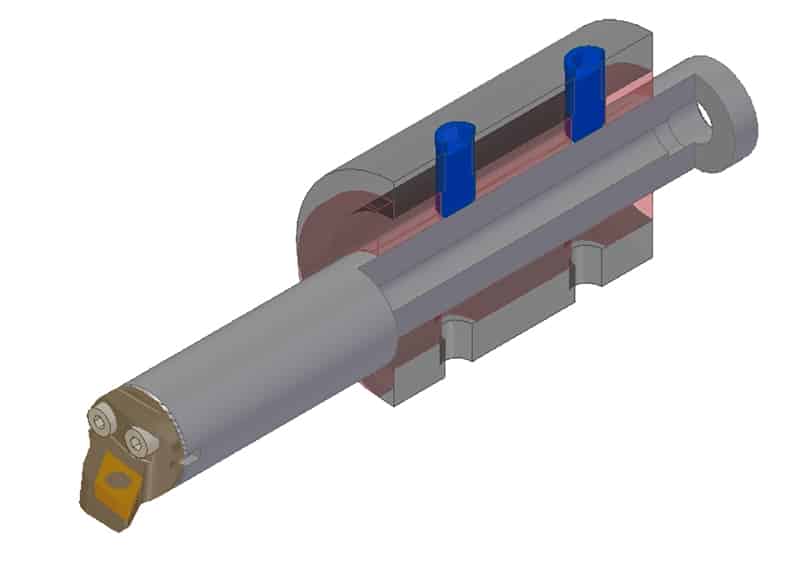

Our Anti-Vibration technology starts with the auto-tuning mass damper. Cogsdill’s tooling is unique due to the complex polymers that surround a tungsten mass within the boring bar. Vibration frequencies differ significantly over varying lengths. The polymers in turn respond by changing their form, adjusting to the cutting frequency which counteracts vibration – automatically and consistently – effectively auto-tuning the “sweet spot” with no manual adjustment required.

Our Anti-Vibration technology starts with the auto-tuning mass damper. Cogsdill’s tooling is unique due to the complex polymers that surround a tungsten mass within the boring bar. Vibration frequencies differ significantly over varying lengths. The polymers in turn respond by changing their form, adjusting to the cutting frequency which counteracts vibration – automatically and consistently – effectively auto-tuning the “sweet spot” with no manual adjustment required.

Turning a complex technology into a simple plug-and-play solution.

Turning a complex technology into a simple plug-and-play solution.

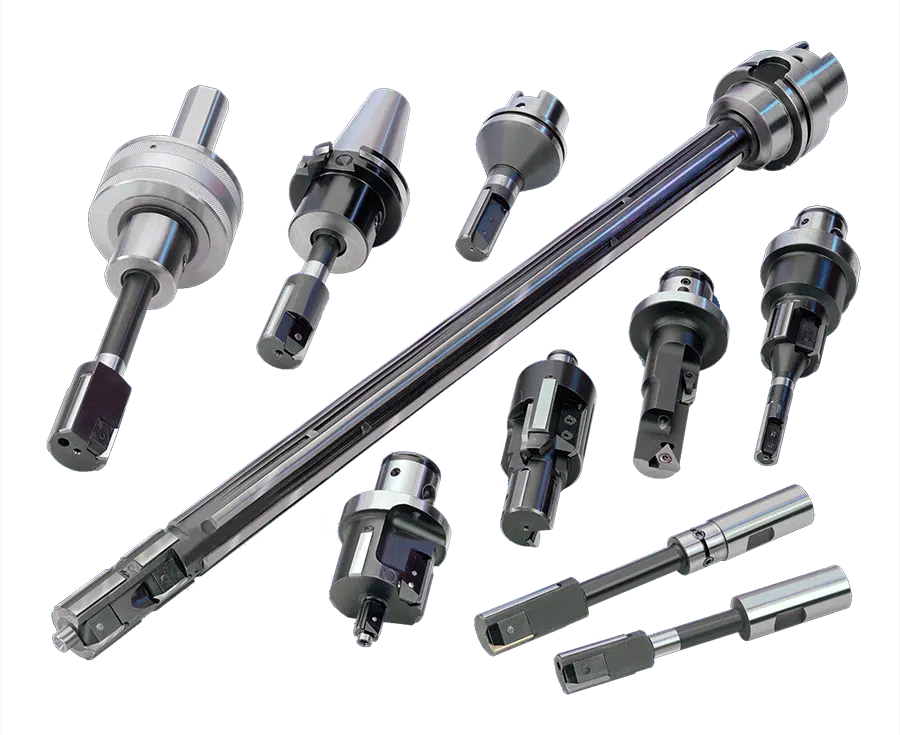

QUICK CHANGE

Designed with a quick-change interface that incorporates a serrated coupling for alignment and secure tightening. With our exchangeable heads, you can switch from turning/boring to burnishing in seconds with repeatable results time after time.

QUICK CHANGE

Designed with a quick-change interface that incorporates a serrated coupling for alignment and secure tightening. With our exchangeable heads, you can switch from turning/boring to burnishing in seconds with repeatable results time after time.

Anti-Vibration Diamond Burnishing Tools (AVDBT)

Benefits

- Instant set-up (plug-and-play)

- No manual tuning / adjustments required

- Turn, bore and burnish from one tool

- Internal bores & external diameters

- Internal through coolant

- Greater working length

- Superior surface finishes

- Incredible cost efficiencies

- Guaranteed repeatability

Anti-Vibration Diamond Burnishing Tools (AVDBT)

Benefits

- Instant set-up (plug-and-play)

- No manual tuning / adjustments required

- Turn, bore and burnish from one tool

- Internal bores & external diameters

- Greater working length

- Superior surface finishes

- Incredible cost efficiencies

- Guaranteed repeatability

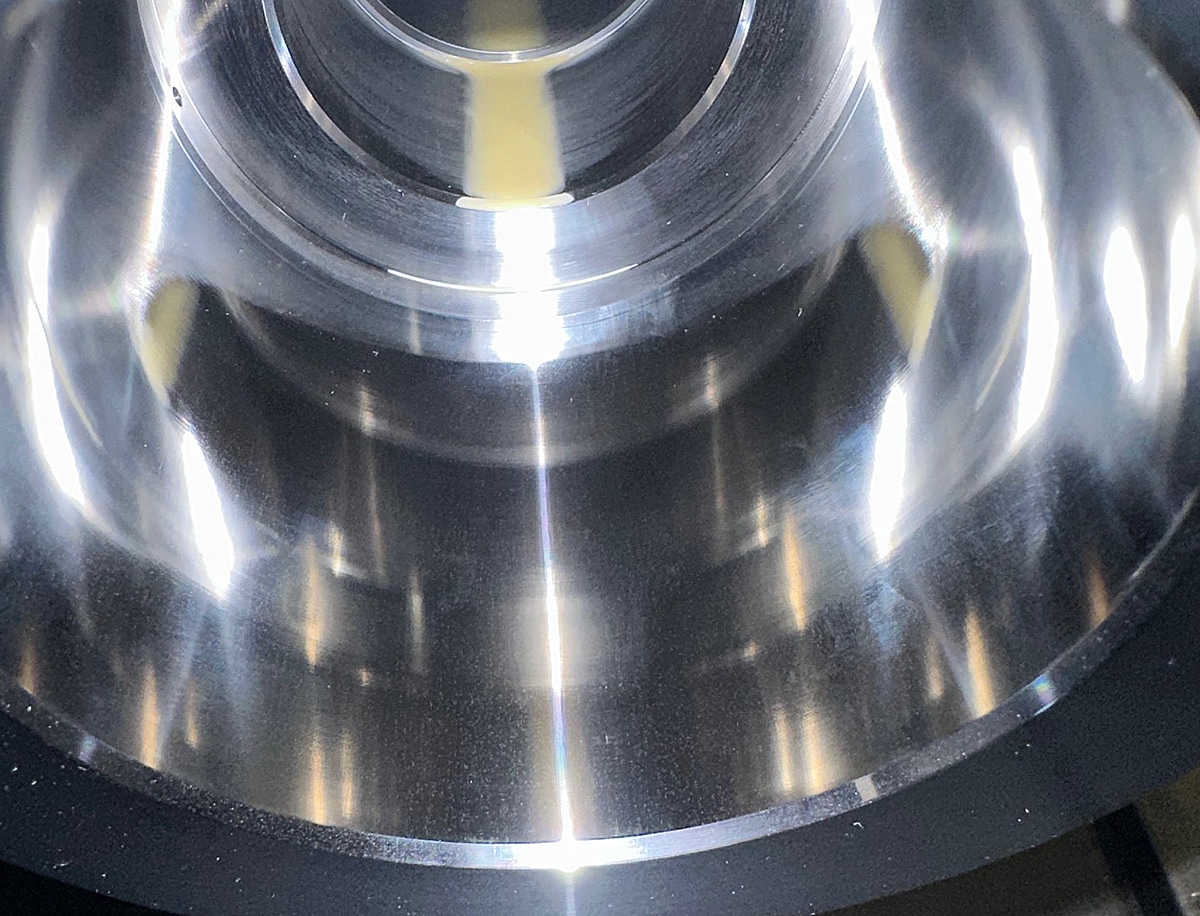

Chatter-free. Mirror-like finish.

Turning, boring and burnishing… one set-up now really does do it all.

We hold a range of tools and spare diamond nibs in stock.

Available for immediate shipping!

Standard Tool Specifications

AVDBT 25mm Series

| Tool No. | E | L3 | G | L4 | L1 Max | F | D | H | Weight (Kg) |

| AVDBT-25-255 | 25 | 255 | 75 | 275 | 200 | 16.4 | 32 | G1/4″ | 1.1 |

| AVDBT-25-330 | 25 | 330 | 75 | 350 | 275 | 16.4 | 32 | G1/4″ | 1.7 |

| AVDBT-25-430 | 25 | 430 | 75 | 450 | 375 | 16.4 | 32 | G1/4″ | 2.2 |

AVDBT 40mm Series

| Tool No. | E | L3 | G | L4 | L1 Max | F | D | H | Weight (Kg) |

| AVDBT-40-408 | 40 | 408 | 120 | 428 | 308 | 24 | 50 | G1/2″ | 3.9 |

| AVDBT-40-528 | 40 | 528 | 120 | 548 | 428 | 24 | 50 | G1/2″ | 5.0 |

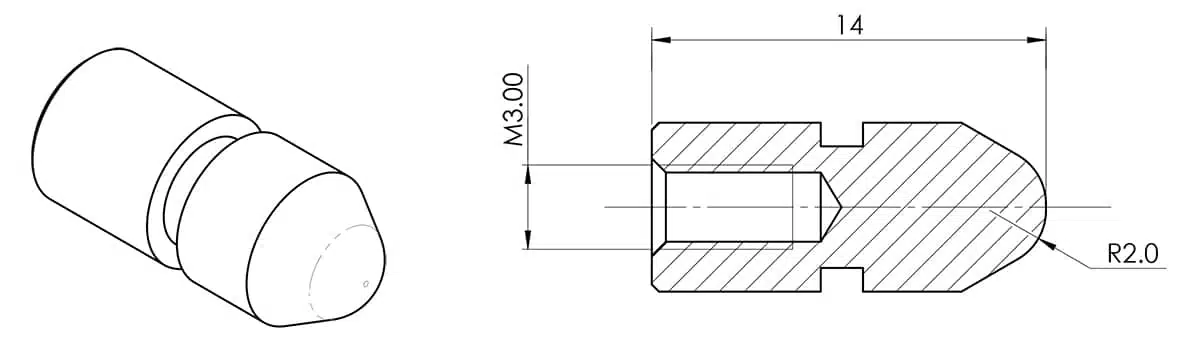

Nib Specifications

AVDBT-03

Machine clamping requirements

To ensure these tools give the optimum performance, correct tool holding is critical. These tools are not designed to be clamped directly on to the shank because the low surface area of clamping will not provide sufficient rigidity. Furthermore, direct contact of the screws will damage the dampening system. You should use a standard adapter for mounting the tool, via means of reduction sleeve, all around clamping or preferably hydraulic collet / shrink-fit clamping for maximum rigidity / bending stiffness.

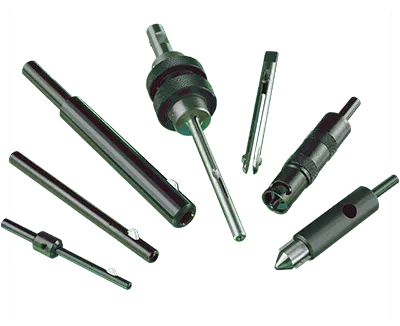

Direct Screw Mount

- Unacceptable rigidity due to single point of contact

- DO NOT USE THIS

- It will damage the bar

Reduction Sleeve

- Acceptable Rigidity / Bending Stiffness for low L/D

- Clamping Length = 4xD

All Around Clamp

- Better Rigidity / Bending Stiffness

- Clamping Length = 4xD

Hydraulic Collet

- Best Rigidity / Bending Stiffness

- Recommended for high L/D

- Clamping Length = 3xD

Test Results

EN19

| Machine & Component Data | |

| Machine | Mazak Integrex 400 |

| Bore Diameter | 104.7mm |

| Bore Depth | 103mm |

| Tools Used | |

| Tool | AVDBT-25-255 |

| Bar Length | 255mm |

| Insert | Sandvik DCMT11T304PM |

| Boring Data | |

| Speed | 200 m/min |

| Feed | 0.15 mm/rev |

| Depth of Cut | 0.25 mm |

| Surface Finish Achieved | 1.8 Ra |

| Burnishing Data | |

| Speed | 200 m/min |

| Feed | 0.1 mm/rev |

| Depth of Cut | 0.25 mm |

| Interference | 0.2mm (Radial) |

| Surface Finish Achieved | 0.2 Ra |

| Size Change | 0.012mm |

1.8 Ra surface finish with boring head

0.2 Ra surface finish with burnishing head

4340

| Trial Data | |||

| Product | Setup | After Turning | After Burnishing |

| AVDBT-25-255 | 7xD | 1.7 Ra µm | 0.3 Ra µm |

| AVDBT-25-330 | 10xD | 1.5 Ra µm | 0.3 Ra µm |

| AVDBT-25-430 | 14xD | 2.1 Ra µm | 0.3 Ra µm |

| AVDBT-25-430 | 15xD | 2.0 Ra µm | 0.3 Ra µm |

Typical grinding surface finish:

0.3 – 0.8 Ra µm

1.49 Ra surface finish with boring head