One for the Chamber

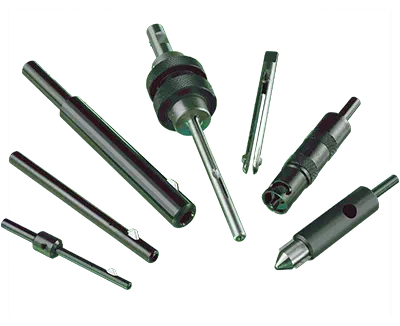

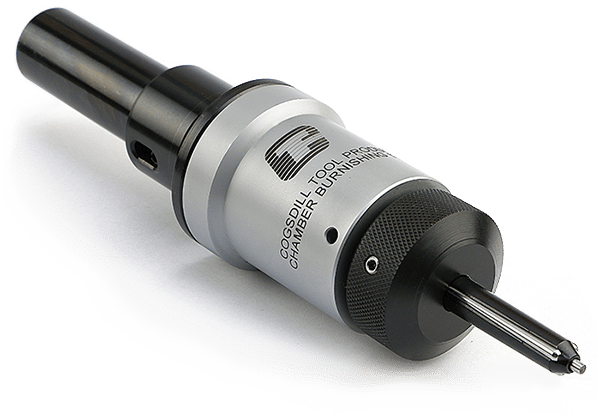

Ensure trouble-free shell casing ejection with the Cogsdill Gun Chamber Burnishing Tools (CBT).

The chamber burnishing tools have been designed to the Sporting Arms and Ammunitions Manufacturers Institute (SAAMI) standard for Handgun and Rifle Chamber geometries.

Our selection of chamber burnishing tools cover standard calibers from leading manufacturers including Smith & Wesson, Colt, Magnum, Remington, Winchester, Springfield, SIG Sauer and many others.

Redefining convention

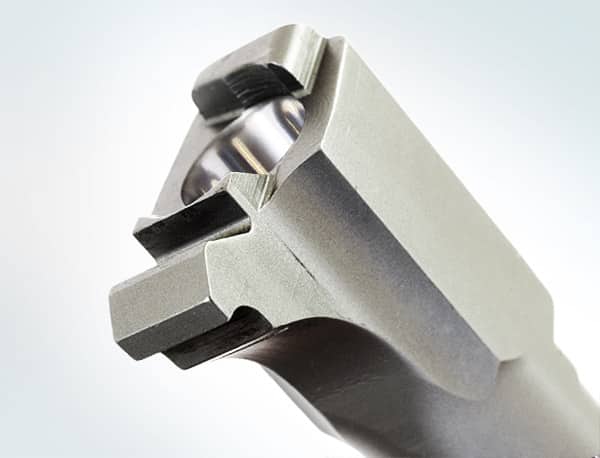

The conventional manufacturing process for armament shell chambers is reaming with a profiled reamer. Our expanding chamber roller burnishing tools enhance the reamed bore by producing an extremely fine surface finish (15 micro inches or less), which produces improved performance, repeatable shell ejection and preventing jams.

Due to the fact that no metal is removed in the process, the surface finish depends on the existence of a uniform and tear-free reamed finish which will be caused to flow under the force exerted through the rolls.

Our standard CBT are available from stock with many other chamber configurations available upon request.

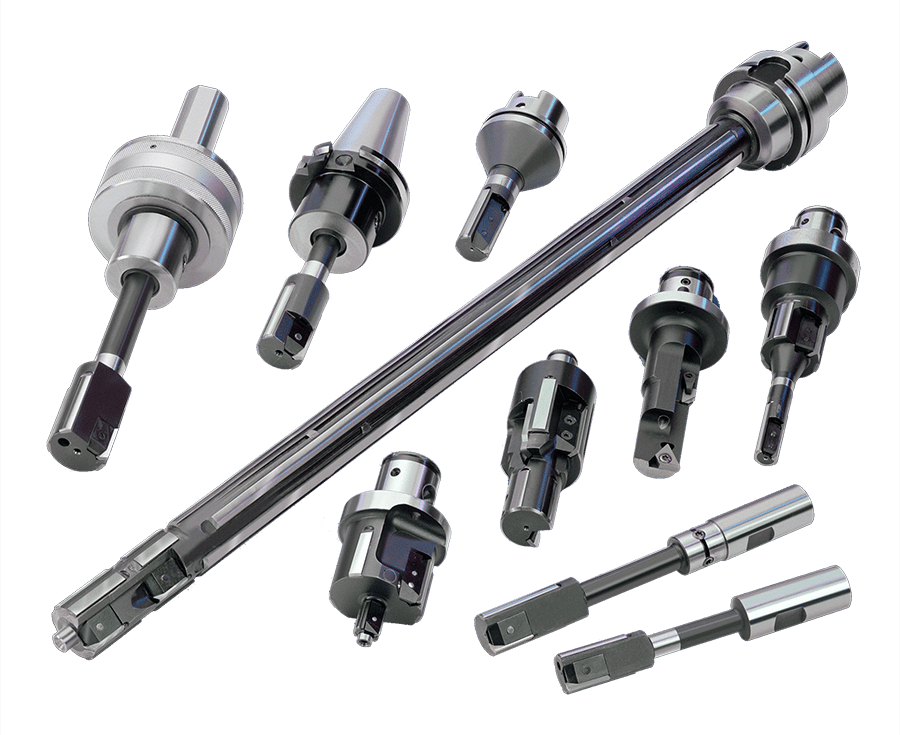

CBT Tool Operation

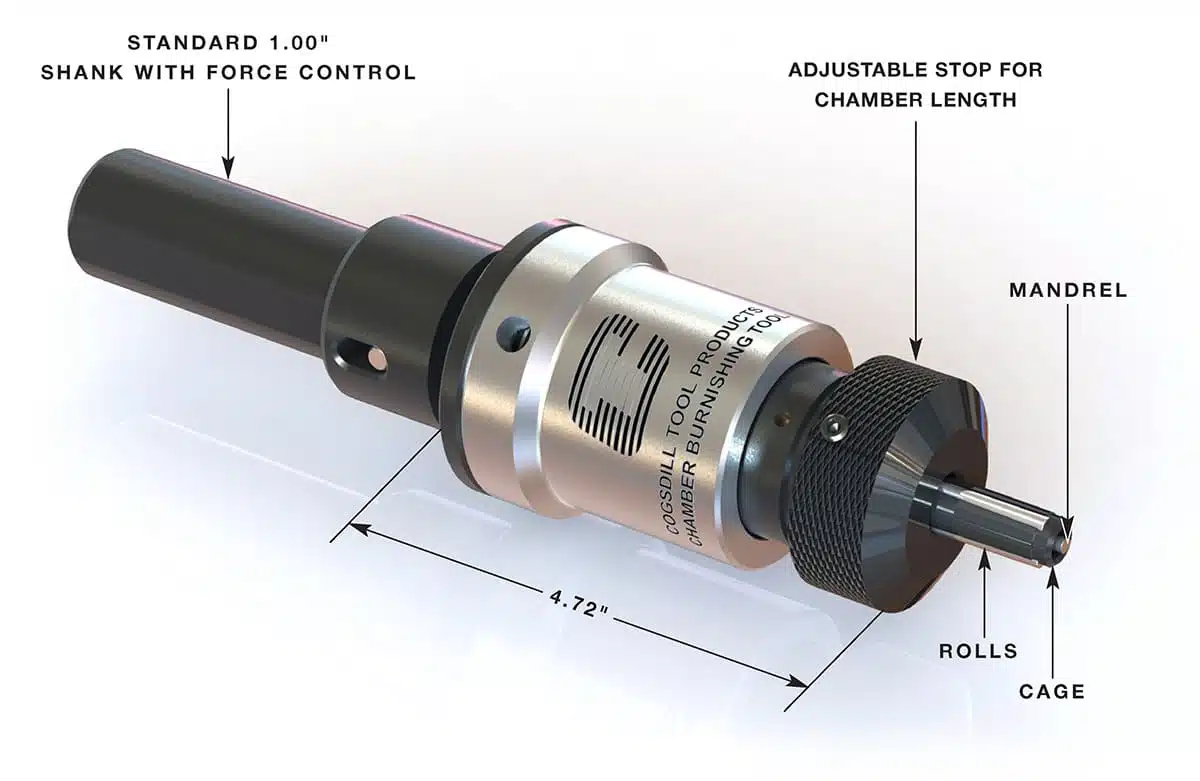

| 1 | The expanding chamber roller burnishing tool applies a steady rolling force of approximately 400lbs per 1/16 inch of roll length to the surface of the chamber. |

| 2 | Applying this rolling force is acheived through the use of hardened tapered rollers that are held in place by a cage and rotate around an inversely tapered mandrel. |

| 3 | The tool locates in the bore of the chamber and the bearing mounted stop thrusts off the front of the component to expand the rollers, which exerts burnishing force onto the surface of the chamber, resulting in a smooth surface finish in one pass. |

| 4 | The rollers collapse automatically when the tool is retracted to prevent damage to the bore. |

| 5 | The tool is equipped with an overtravel mechanism to ensure guaranteed repeatability and control the rolling force upon the chamber surface. |

Gun Chamber Burnishing Tools (CBT) are versatile

- Create an ultra-smooth chamber finish in one pass in seconds.

- Offers a simple burnishing process for use after chamber reaming.

- Improved chamber quality, spent shell ejection, & loading speed.

- Fast, easy tool set-up and operation. No special skills required.

- Versatile – use in any spindle from drill press to CNC machine.

- Easy to maintain, high quality tooling made by toolmakers.

- Affordable tools and spare parts readily available from stock.

Improved Quality. Trouble-free Ejection.

An ultra-smooth gun chamber finish. Enhance performance, spent shell ejection and loading speed.

A standard range of tools and parts are available from stock.

Please contact us for delivery.

Standard Tool Specifications

Standard calibers currently available*

| Handgun | Rifle | ||

| Caliber | Tool Number | Caliber | Tool Number |

| 9mm | CBT-9MM | .223 Remington | CBT-223-REM |

| .380 auto | CBT-380-AUTO | .243 Winchester | CBT-243-WIN |

| .38 auto | CBT-38-AUTO | .308 Winchester | CBT-308-WIN |

| .357 Magnum | CBT-357-MAG | .270 Winchester | CBT-270-WIN |

| .357 Sig | CBT-357-SIG | .30-06 Springfield | CBT-30-06-SPR |

| .40 S&W | CBT-40-S&W | 7mm Remington Mag | CBT-7MM-REM |

| .45 ACP | CBT-45-ACP | .30-.30 Winchester | CBT-30-30-WIN |

* Contact Cogsdill for availability of other calibers

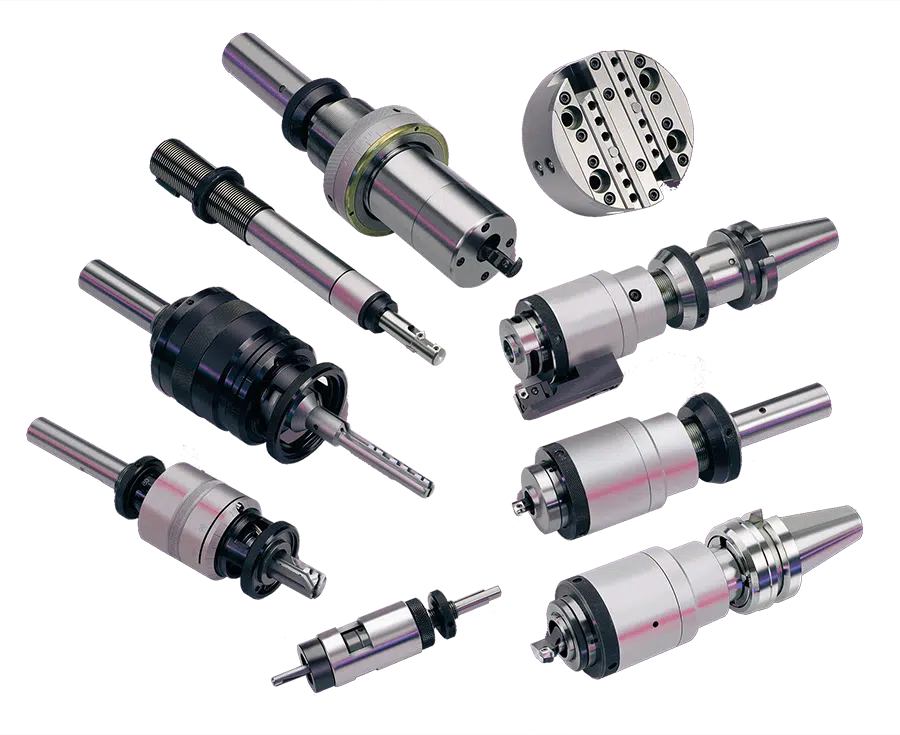

Tool Settings

There are only two adjustments, or settings, that can be made to the expanding roller burnishing tool:

| 1 | The burnishing force can be controlled by the amount of compression of the overtravel unit to perfectly finish the chamber surface. |

| 2 | The burnishing length can be adjusted to ensure the entire surface area of the chamber is roller burnished. |

| See Instructions » |