Automotive

The automotive industry has been a major part of Cogsdill’s customer base since the company was founded in Detroit in 1914. Today, we partner with automotive companies and suppliers on a worldwide basis, offering standard and special solutions for machining operations ranging from simple to complex.

Our Shefcut Reaming, Roller Burnishing and Deburring tools are Cogsdill’s major offering to this industry from our vast tooling portfolio.

The Problem Solver

Synonymous with automobile manufacturing for over a century.

Cogsdill has been designing and manufacturing special tools for the automotive industry for over 100 years. Pioneers such as Henry Ford and the Dodge brothers, relied on Cogsdill to develop innovative tooling solutions for their tough manufacturing problems. Our founder, Stuart Cogsdill established himself from the outset as ‘the problem solver.’ A heritage we are proud of and still the reason why top marque automobile manufacturers and leading global racing teams rely on us for their finishing touch.

Today, Cogsdill relies on their vast experience in dealing with automotive engineers worldwide to develop new tooling for a variety of applications. Be it machine builder, OEM or tier supplier, Cogsdill can assist and support new projects and processes for maximum productivity and cost reduction efforts.

Whether the application requires a low micro-finish, precision bores, deburring or grooving Cogsdill can help. Please contact us or one of our sales engineers today to discuss your project.

Countless Components

(It’s easier to list the automotive parts we don’t do.)

Regardless of the component or function, Cogsdill has the experience to design and manufacture the right tooling get the job done. From camshaft towers and valve guide bores, transmission valve bodies to crankshafts, hydraulic components, I.D.s, O.D.s, shafts, bores and other surfaces, Cogsdill has the experience to give your part the finishing touch.

A selection of automotive components that utilize Cogsdill tooling:

- Engine Blocks

- Steering Housings and Components

- Torque Converters

- Hydraulic Valve Bodies

- Transmission Cases and Hubs

- Clutch Housings

- Universal Joints

- Rear Axle Differentials

- Crankshafts and Con Rods

- Turbochargers and Impellers

- Brake Rotors/Discs and Callipers

- Exhaust Manifolds

- Pistons, Valve Guides and Seats

- Fuel, Oil and Water pumps

- Brake Cylinders

- Suspension Arms

- Power Steering Units

- Fuel Injectors

- Alloy Wheels and Valves

- Hood and Trunk Gas Struts

- Even the locks on glove boxes

- and many, many more.

On or off the track.

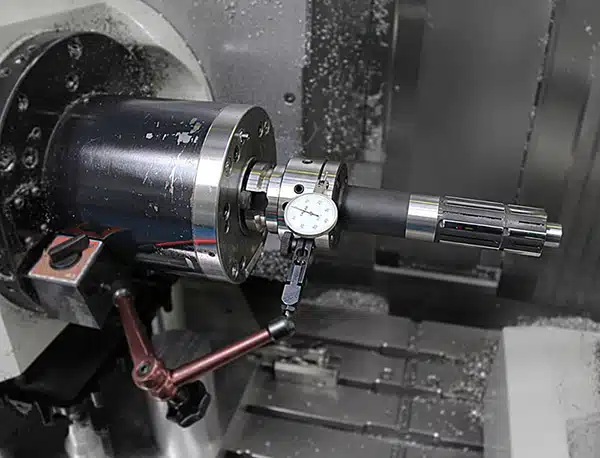

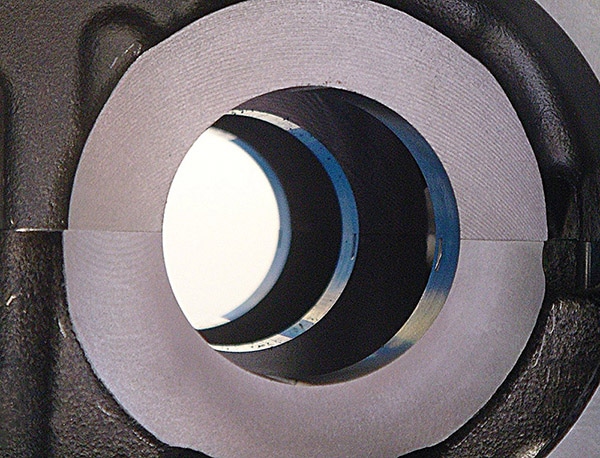

Accurate sizing and superior bore geometry with consistent performance.

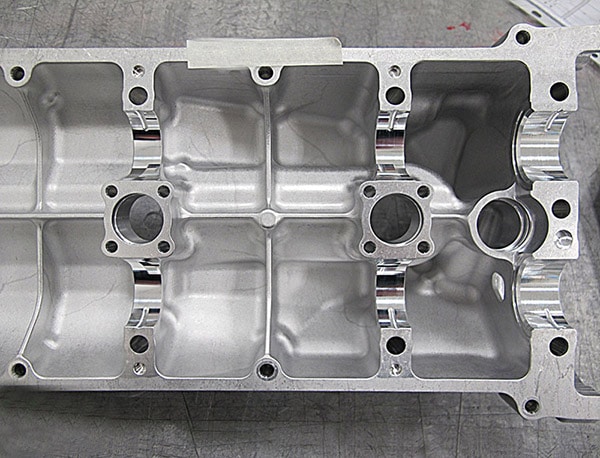

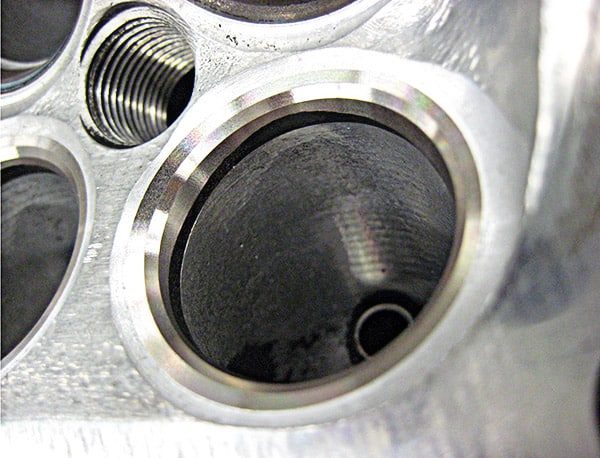

Cylinder Heads

Product features:

- Machining camshaft bores on machining center line: Shefcut short-length pad-guided tool semi-finishes and finishes first journal. Piloting in finished first journal, Shefcut long-length pad-guided tool semi-finishes and finishes remaining journals.

Machining camshaft bores on transfer line: Shefcut pad-guided tool, piloting in precision guide bushing, semi-finishes and finishes all journals. - Shefcut precision boring tool machines valve guide and valve seat bores.

- Shefcut precision boring tool machines lash adjuster bores.

- Shefcut precision boring tool machines water outlet bores.

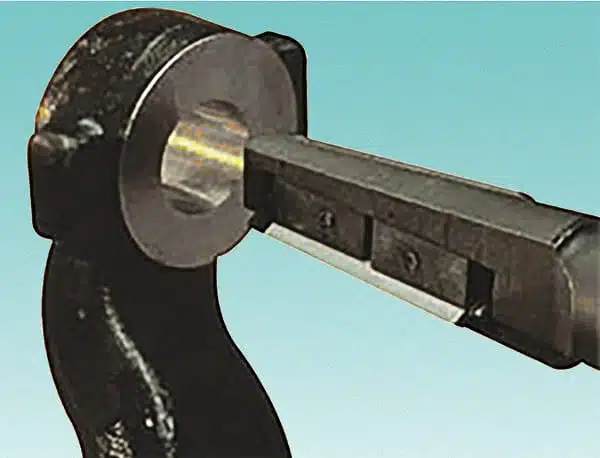

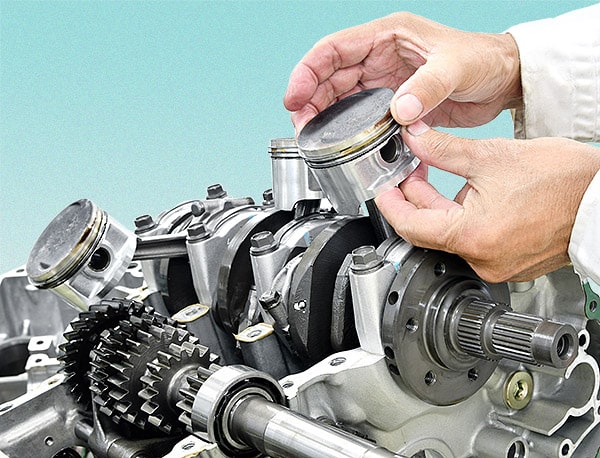

Connecting Rods

Product features:

- Wrist pin bores on connecting rods can be finished with any of three solutions from Cogsdill: Shefcut pad-guided precision boring tool, or either of two burnishing tool designs, Bearingizing or Roll-a-Finish tool.

- Crank bores on connecting rods are best finished with Shefcut pad-guided precision boring tool: radial forces are kept to a minimum, ensuring no cap-to-body separation, while producing quality bore.

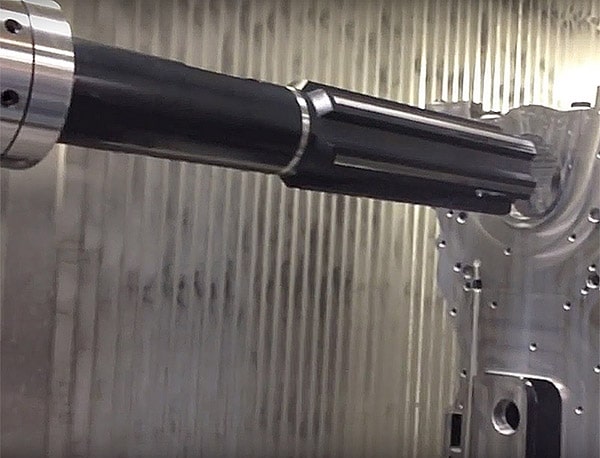

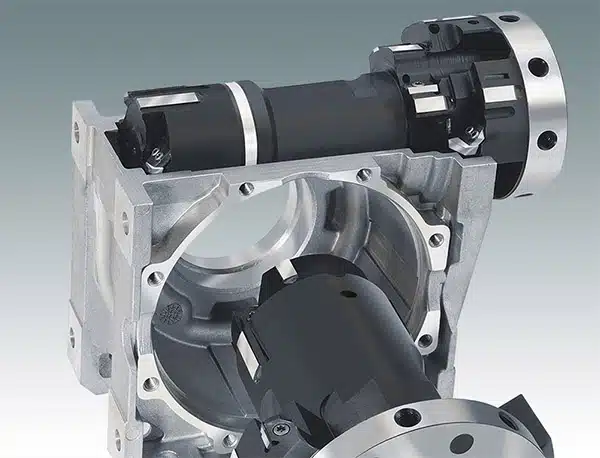

Oil Pumps

Many different Cogsdill tools are applied on this one component:

Product features:

- Rough-boring tool machines bores from cast condition.

- Shefcut precision boring tool finishes critical bores.

- Generating Head performs boring, facing, and chamfering operations.

- Automatic Recessing tool machines back-chamfers.

- Burraway tool deburrs front and back corner breaks on drilled holes.

Brake Systems

A variety of solutions for machining master cylinders, wheel cylinders, and brake calipers:

Product features:

- Air-compensating burnishing tool finishes main bore in master cylinder and wheel cylinder.

- Shefcut precision reamer finishes main bore in master cylinder and wheel cylinder.

- Automatic Recessing tool machines boot groove in brake calipers.

- Generating Head machines boot groove in brake calipers.

- Automatic Recessing tool works as coining arbor to punch and chamfer oil holes in master cylinder.