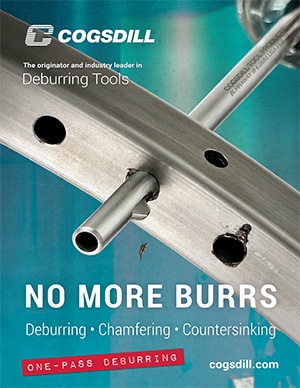

Deburring Tools

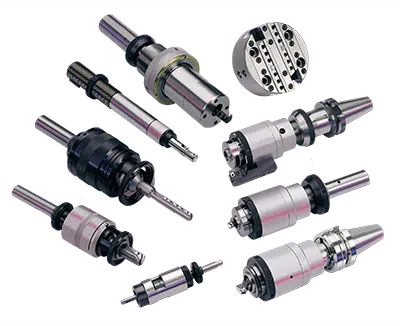

Cogsdill offers you a better way to get rid of those troublesome burrs. BURRAWAY® and BURR-OFF® mechanical hole-deburring tools remove burrs on the front, back, or both sides of drilled holes in one pass… fast, easy, and economical solutions for your hole-deburring problems!

Both Sides in One Pass

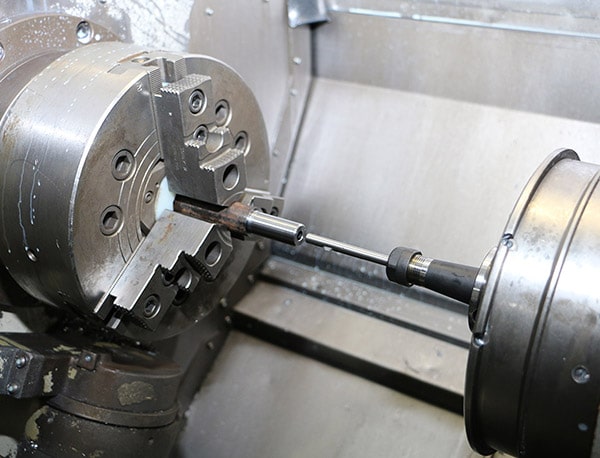

A burr is found on the entrance and exit of a drilled hole and the degree and size of the burr is dependent on the material and sharpness of the drill. Deburring holes is usually a costly and time-consuming operation, with the back sides of holes being particularly difficult as they are frequently inaccessible with conventional deburring tools. We eliminate the need to deburr by hand by providing different styles of tools to suit many applications.

Cogsdill is the industry leader and the originator of ‘one-pass deburring’ – which allows the user to easily deburr the front and back of the holes in one single pass. This means that unwanted material on the front and backside of the hole will be deburred in seconds!

Complete with different coatings, blade styles and cutting-edge geometry options to suit different materials – as well as simple change mechanisms and tension adjustments – Cogsdill gives you the most flexibility of any deburring tool.

A range of inch and metric tool sizes and blades are always held in stock.

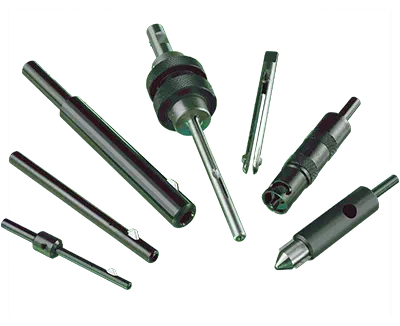

Tools available:

- Deburring tools (inc. Elliptical deburring)

Offers a consistent deburring of even and uneven bore edges – both front and back – in one operation. - Chamfering tools (inc. Back-Spotfacing)

An economic way for front and back chamfering in one operation, complete with easy blade changes. - Countersinking tool

The ultimate in precision countersinking to enlarge and bevel the rim of any drilled hole.

Simple tool adjustments. Multiple cutting geometries.

Incredible cost efficiencies.

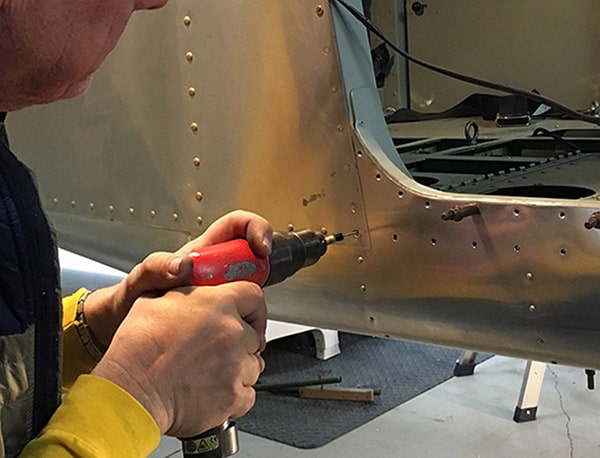

Cogsdill is proud to be trusted to ensure the precision finishing of countless components from leading manufacturers around the world. With a suite of Deburring tools and blades to match every scenario and material, both flat and irregular shapes can be finished to exacting standards in a fast and simple manner – ensuring production time is maximised without negating precision, performance and accuracy.

The tools range from 1.57mm / 0.093” (3/32) through to 50mm / 2 inches in both metric and imperial as standard, with other sizes available upon request. The Deburring tools are suited for CNC set-ups, power tools as well as hand-finishing to suit your own specific manufacturing requirements, with many quick-change and simple tension adjustments as standard.

Multiple blade options are available, including High Speed Steel (HSS), HSS with a TiN (Titanium Nitride) coating or Carbide tipped, and offer positive, negative and neutral rakes as well as front acting, back acting or double acting – to ensure everything from hard plastics (CFRP/GFRP), Brass, Aluminium, Steel and Stainless Steel, Cast Iron, Inconel 718 as well as countless other materials – can be finished effortlessly and efficiently.

Each application raises it’s own specific tooling requirements. Here are just some of them:

- Prop Shafts

- Derailleur Gears

- Coupling Flanges

- Turbine Shafts

- Rotor Hubs

- Alloy Wheels

- Wheel Hubs & Spacers

- Drilled Brake Discs

- Common Rails

- Spindle Housings

- Pivot Bolts

- Cylinder Heads

- Crankshafts

- Valve Guides

- Connecting Rods

- Manifolds

- Differentials

- Fly Wheels

- Turbochargers

- Gear Housings

- Steering Joints

- And many more…

The industry leader and the originator of ‘one-pass deburring’

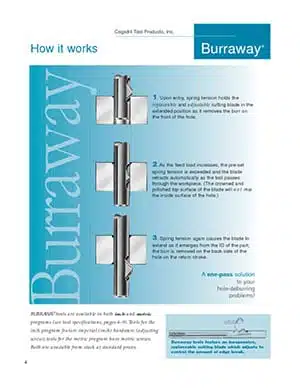

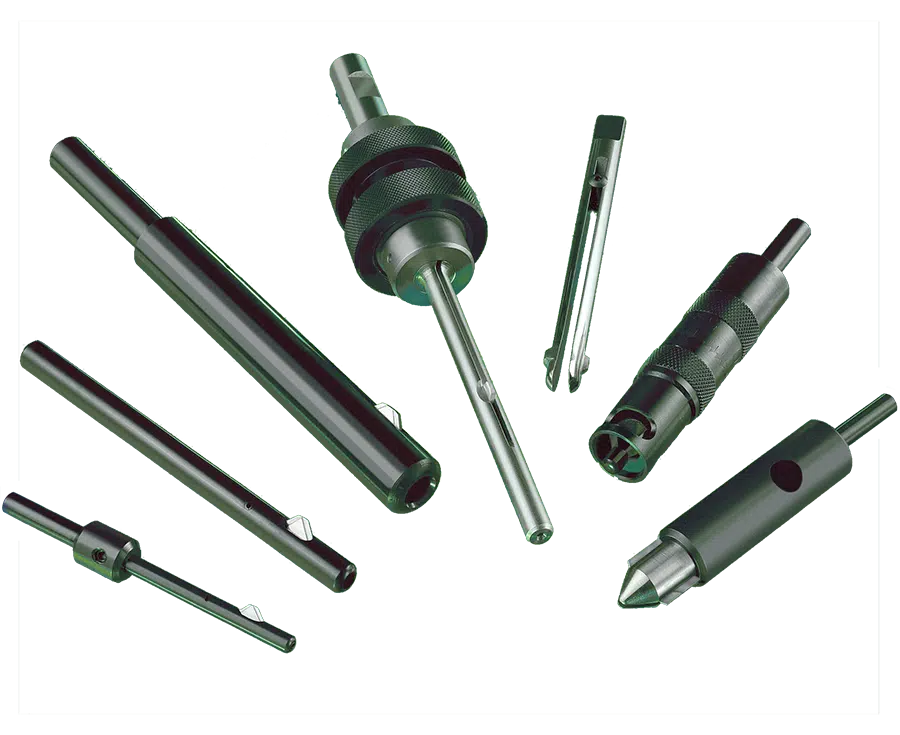

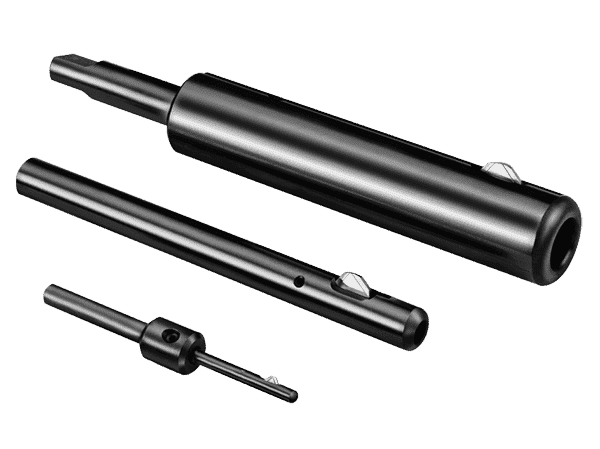

Burraway

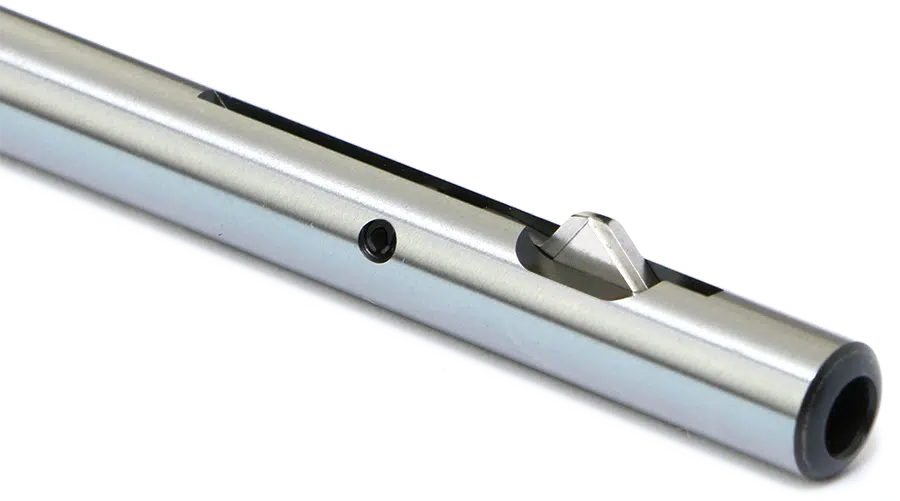

The Burraway® features a replaceable and inexpensive cutting blade which can be adjusted to control the amount of edge break for consistent results from part to part.

The tool can remove feather edges or heavier burrs, on both sides of the hole, working from one side only.

The Burraway can be used in fixed spindles or in portable power tools – no need for complicated fixturing, and no special operator skills are required.

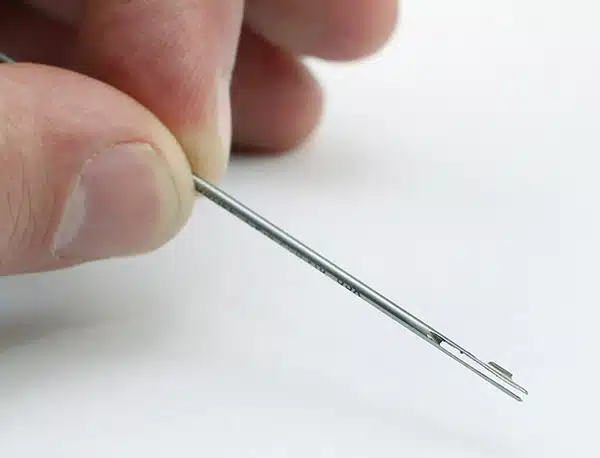

Micro Burraway

The Micro Burraway series of tools will deburr both sides of even the smallest of holes in one pass.

Suitable for materials such as aluminum, steel, stainless steel, titanium and even composites, these micro deburring tools suit holes ranging from .040″ (1.00mm) to .092″ (2.33mm).

The two-piece construction allows you to remove and replace a cartridge in a matter of seconds while the micro tool is still in the spindle, with a convenient set screw securing the cartridge’s brass sleeve within the holder.

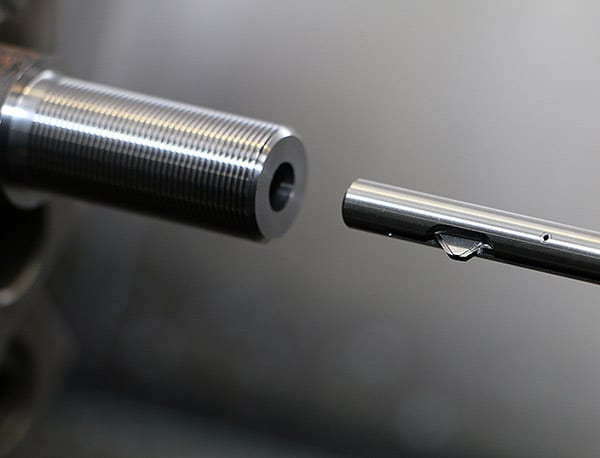

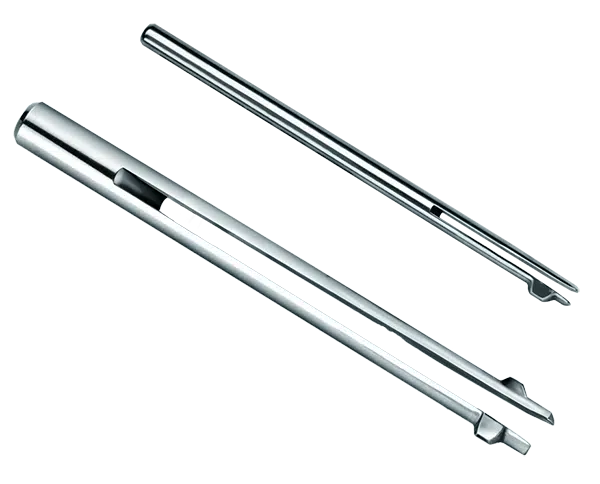

Burr-Off

The Burr-Off® operates on the same basic principle as the Burraway®, but is designed for high-production, automated deburring operations. The open-slot design of the “clothespin tool” allows chips to clear easily, which makes the tool ideal for automatic equipment and multi-spindle machines. Just like the Burraway, the Burr-Off deburrs the front, back, or both sides of holes in one fast pass.

The Burr-off is a simple one-piece construction. The integral cutting edges can be altered upon request for front or back-cutting only.

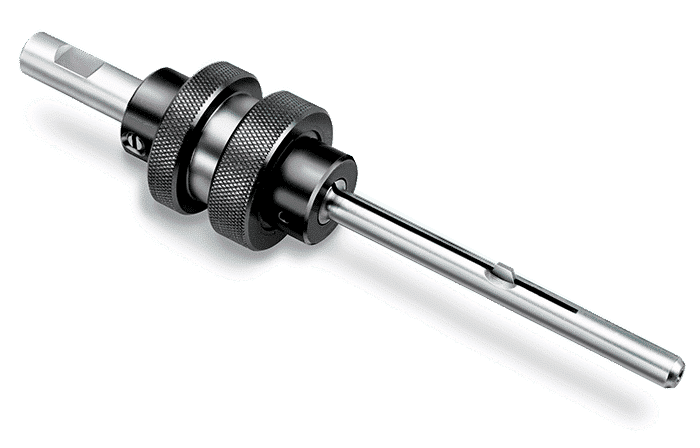

Micro-Limit

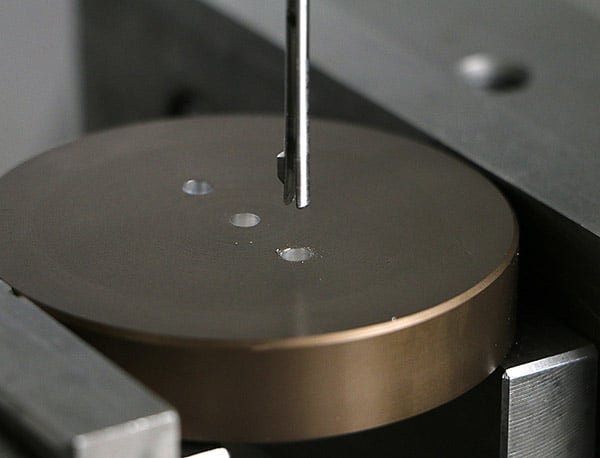

The Micro-Limit is a precision depth-control countersinking tool. The tool consists of a drive with a piloted countersink and a depth control adjustment feature.

The tool is pre-set to the desired depth of cut. The selected setting is locked in for accurate and consistent results from part to part.

The pilot is engaged in the hole. A stop collar seats on the face of the workpiece; the tool advances to countersink the hole to the desired depth.

The Micro-Limit drive is designed and built for rugged production work. The thrust load is taken up on ball bearings through a hardened steel stop collar. The drive shaft rides on needle bearings. This design makes our drive the longest lasting in the industry.

Three drive models cover a wide range of hole sizes. Adjustment is in increments of .001 inch (.025mm).

Ellipti-Bur

The Ellipti-Bur® is designed for deburring irregular hole surfaces, such as those which are generated by drilling into curved surfaces, or by drilling at an angle. The Ellipti-Bur enables the user to perform these difficult deburring operations quickly and accurately, and without jigs, fixtures, or special operator skills.

As the pilot of the tool is located in the hole, the tool is seated and centered. As the tool is advanced, the pilot is forced into the tool body against the shank spring, and the blade comes into contact with the edge of the hole. As the tool continues to advance, the pilot is further pressed into the body and the blade is driven into the workpiece.

The blade remains free to react to the irregular surface geometry of the hole, allowing for both radial and axial displacement resulting from the elliptical shape of angular drilled holes, and axial displacement (“rise and fall”) from the saddle shaped configuration of holes drilled in cylindrical surfaces.

Flipcut

The Flipcut™ tool is designed to perform back-spotfacing or back-chamfering operations in one set-up. The cutter extends, with right-hand rotation of the tool, to cut the back spotface or back chamfer. Left-hand spindle rotation initiates positive mechanical closure of the cutter; the closing action is assisted by centrifugal force. When the cutter is fully enclosed within the arbor pocket, the tool can be easily withdrawn from the bore.

The Flipcut tool is designed for rugged use on all types of plant equipment and in all kinds of manufacturing environments. Tools for hole sizes from .312 inch and above (inch program) and tools for hole sizes from 8.00mm and above (metric program) have internal coolant capability.

Flipcut cutters are a brazed carbide design. Steel body absorbs shock. The brazed carbide Flipcut cutting edge dissipates heat, for outstanding cutting performance.

Nobur Tool

The Nobur® Tool is a manually actuated deburring and chamfering tool for use where production requirements are low. The tool is used on multi-walled parts and on intersecting holes. It will remove severe burrs and will produce non-qualified chamfers. The tool body pilots in the hole to be deburred. A quick-action sliding sleeve extends the retractable, double-edged cutting blade to deburr or chamfer the front, back, or both sides of holes, in one pass of the tool.

Since the tool is manually actuated while the spindle continues to run, there is no “on-off” down time.