Flippin’ Genius

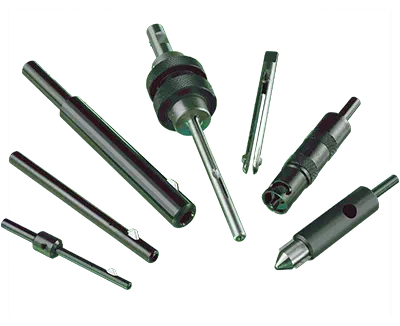

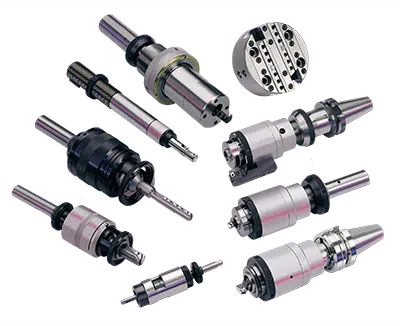

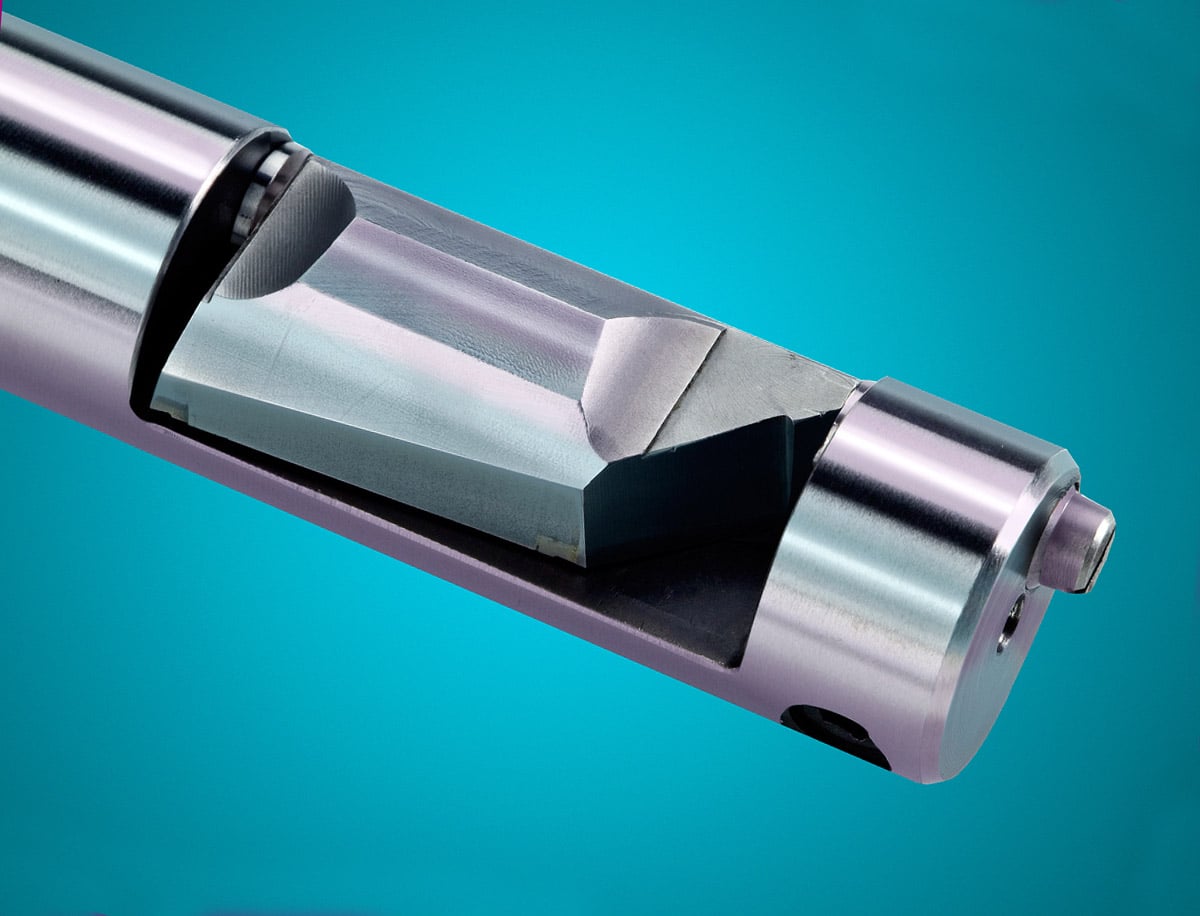

The Flipcut tool is designed to perform back-spotfacing or back-chamfering operations in one set-up. The cutter extends, with right-hand rotation of the tool, to cut the back spotface or back chamfer. Left-hand spindle rotation initiates positive mechanical closure of the cutter; the closing action is assisted by centrifugal force. When the cutter is fully enclosed within the arbor pocket, the tool can be easily withdrawn from the bore.

The Flipcut tool is designed for rugged use on all types of plant equipment and in all kinds of manufacturing environments. Tools for hole sizes from .312 inch and above (inch program) and tools for hole sizes from 8.00mm and above (metric program) have internal coolant capability.

Flipcut cutters are a brazed carbide design. The steel body absorbs shock. The brazed carbide Flipcut cutting edge dissipates heat, for outstanding cutting performance.

Two standard cutters are available from stock:

- Cutter designed for back-spotfacing and front-chamfering operations.

- Cutter designed for back- and front-chamfering operations

cutter designs are available upon request to suit other applications; contact our sales department and request a quotation.

How Flipcut tools work:

| 1 | The front chamfer is machined upon entry into the bore, using right hand rotation (clockwise) of the machine spindle at the appropriate speed (refer to chart on page 10), and .002 IPR (0.05mm/rev). |

| 2 | Left hand rotation (counterclockwise) at a maximum of .008 IPR (0.20mm/rev) will effect mechanical closure of the cutter (aided by centrifugal force) so that the tool can feed through the bore. |

| 3 | The back spotface is machined, using right hand rotation (clockwise) at the appropriate speed (refer to chart on page 10), and .002 IPR (0.05 mm/rev). |

| 4 | Left hand rotation (counterclockwise) at a maximum of .008 IPR (0.20mm/rev) will close the cutter so that the tool can be retracted from the bore. |

NOTE: Coolant should be shut off when retracting cutter to ensure cutter closure.

We hold a range of inch and metric tools and assortment of blades in stock.

Available for immediate shipping!