Get into the groove

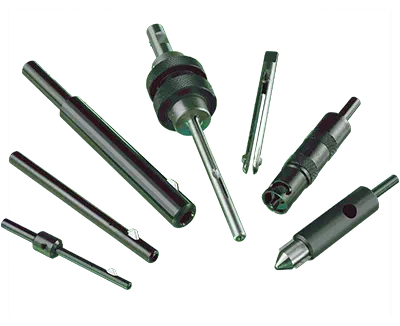

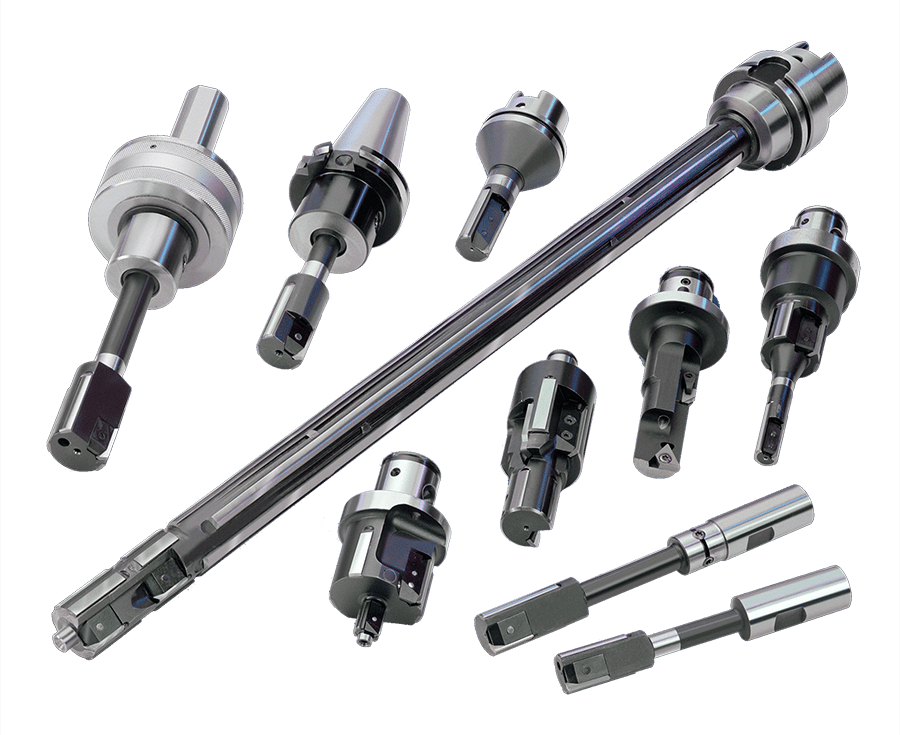

Automatic recessing tools are for machining precision internal and external grooves and recesses on virtually any type of machine. The AR Series Automatic Recessing Tool is made up of three basic components: head, cutter, and pilot. The head is usually standard and consists of shank and tool body. All cutters and pilots are manufactured to suit your application.

Features:

- Pilots off workpiece or jig plate

- Micrometer stop controls depth of cut

- Tool adjustment controls axial location

- Through-shank coolant is standard

- Overtravel shanks are standard

General Purpose tool for use on:

- Horizontal boring machines

- Screw machines

- Special purpose machines

- Drill presses

- Jig boring machines

- Milling machines

- CNC machines

- Tool lathes

- Turret lathes

Operating Principle

The AR Series Automatic Recessing Tool is made up of three basic components: head, cutter, and pilot. The head is usually standard and consists of shank and tool body. All cutters and pilots are manufactured to suit your application.

Pilots

Pilots are required to locate and stabilize the recessing head in the component bore. All pilots are manufactured to suit the application. Although the basic design and dimensions are standardized as shown in the catalog, the locating diameter of the pilot is designed specifically for your component. Part pilots are retained in the master pilot by three retaining screws.

How AR Series tools work:

| 1 | Approach Stroke: The tool is rotating in a machine spindle. The spindle is lowered, and the tool moves into position. |

| 2 | Feed Stroke: The pilot is located in the bore against the face of the workpiece. Downward pressure causes compression of the recessing head, thereby actuating the slide mechanism which feeds the cutter out radially into the workpiece. |

| 3 | End of Feed Stroke: The correct depth of cut is obtained when the micrometer stop bottoms against the front body, making it impossible to continue the cut. Groove location is controlled by the tool adjustment system on the shank end of the cutter. |

When the spindle is retracted, pressure is relieved, and the tool is withdrawn from the bore. The cutter retracts and returns to its starting position. The piloted bearing absorbs both thrust and rotation. It remains stationary in the bore of the workpiece, under load, until the cutter is fully retracted, thereby preventing scoring of the workpiece.

We hold a range of Automatic Recessing heads in stock.

Please contact us for availability.

Standard Tool Specifications

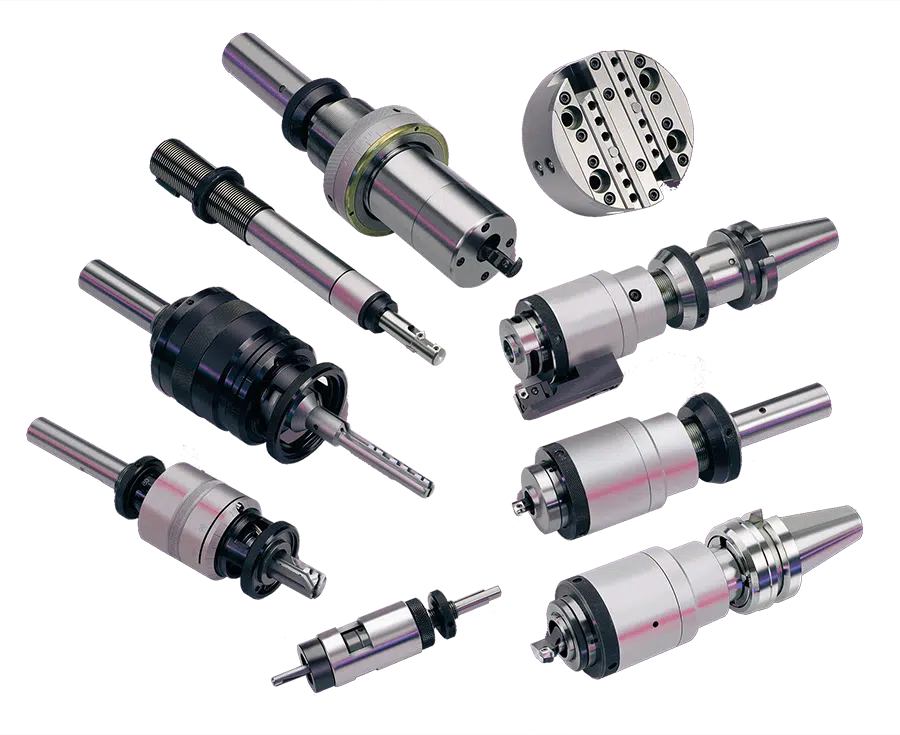

ARSP Short Pilot Head

| METRIC (Imperial) | |||||||||||

| Head | Approximate | Maximum | Shanks | (A) | (B) | (C) | (D) | (E) | (F) | (G) | (H) |

| Type | Capacity Range | Cutter Travel | Free Length | Tool body | Cutter shank | Master Pilot | Ref Min | Bore | Overtravel | Ref to | |

| Cutter Length | Depth | Front Nut | |||||||||

| 5.00mm | |||||||||||

| (0.196″) | |||||||||||

| ARSP2 | 5.00mm | 25.00mm | 93.95mm | Ø60.00mm | Ø12.00mm | Ø27.70mm | 36.50mm | 20.50mm | 1.50mm | 4.00mm | |

| 45.00mm | (0.197″) | (1.000″) | (3.699″) | (Ø2.360″) | (Ø0.472″) | (Ø1.091″) | (1.440″) | (0.810″) | (0.060″) | (0.158″) | |

| (1.772″) | |||||||||||

AR Recessing Head

| METRIC (Imperial) | |||||||||||

| Head | Approximate | Maximum | Shanks | (A) | (B) | (C) | (D) | (E) | (F) | (G) | (H) |

| Type | Capacity Range | Cutter Travel | Free Length | Tool body | Cutter shank | Master Pilot | Ref Min | Bore | Overtravel | Ref to | |

| Cutter Length | Depth | Front Nut | |||||||||

| 5.00mm | |||||||||||

| (0.196″) | |||||||||||

| AR16 | 7.00mm | 25.00mm | 140.90mm | Ø65.00mm | Ø16.00mm | Ø36.00mm | 51.50mm | 30.23mm | 1.50mm | 4.76mm | |

| 45.00mm | (0.276″) | (1.000″) | (5.547″) | (Ø2.360″) | (Ø0.630″) | (Ø1.416″) | (2.030″) | (1.190″) | (0.060″) | (0.187″) | |

| (1.772″) | |||||||||||