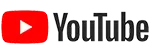

Specially adapted ZX Modular Boring Tools feature piloted cutter support for use

in machining seat pocket areas in oil valves and other extended reach applications.

Valve Seat Pocket Tools

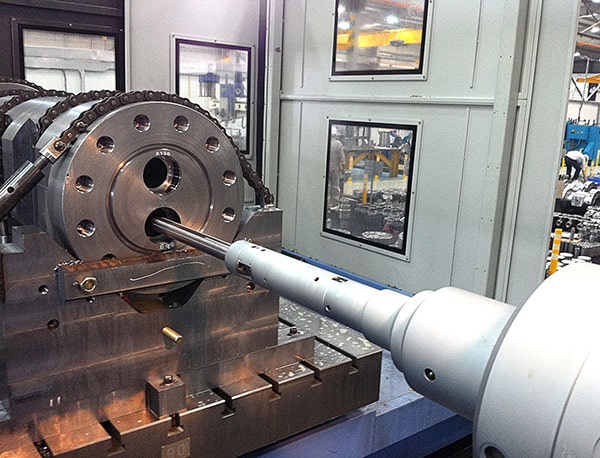

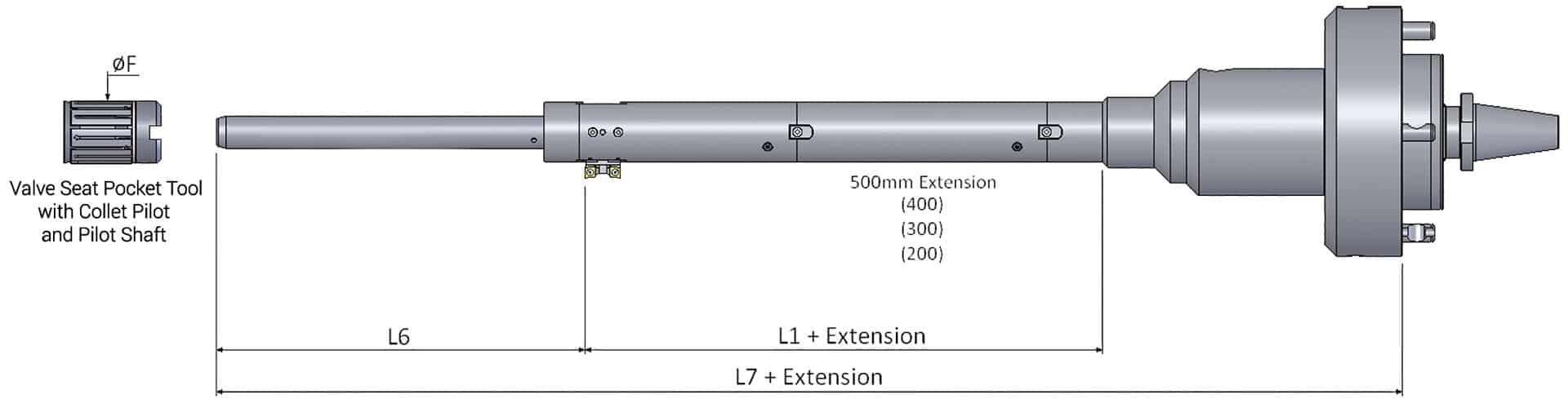

Specially adapted ZX Modular Boring Tools feature piloted cutter support for use in machining seat pocket areas in oil valves and other extended reach applications. Extended and supported long-reaching ZX Modular Boring Tools called Valve Seat Pocket Tools are dedicated to machine cavities or different geometries inside deep bores. Valve Seat Pocket Tools feature an end cap mounted pilot shaft which feeds inside a collet pilot, mounted inside the bore for accurate support during machining operation.

ZX Valve Seat Pocket Tools have enough stroke and strength to rough-machine preclad seat pocket cavities and, using the same tool, to finish-machine the pocket in Inconel after cladding. Non-clad pockets can also be machined. Seat pocket tools are commonly used in steel, stainless steel, and Inconel. All tools feature 2:1 actuation ratio for easy programming.

Complexity simplified. Flexibility extended.

Product features:

- In-bore piloting for rigid cutter support.

- Available in single and twin-slide designs to fit industry-standard flow bore sizes. Supplemental cartridges can be supplied to increase diameter range in special applications.

- Modular construction, in standard lengths: stub, medium, and long reach. (Non-threaded design allows for easy assembly and disassembly of modular sections.)

- Support collet pilots with wrench sets are included on medium and long-reach tools (optional air collets are available).

- Longest tool slide strokes available, for maximum diameter range.

- Internal through-tool coolant is standard.

- Fully enclosed actuation mechanism – no chip packing.

- Internal forward hard stop and anti-torque features protect the tool in case of mishaps.

- Modular damper units are available on smaller-bore tools to dampen vibrations.

- Conversion kits provide ability to easily change tool for use in valves of various sizes.

- A variety of insert cartridges are available, utilising industry standard inserts.

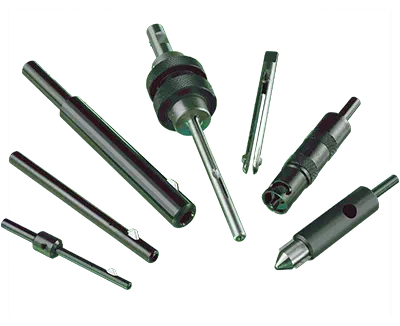

Bottle Boring Tools

Critical Support

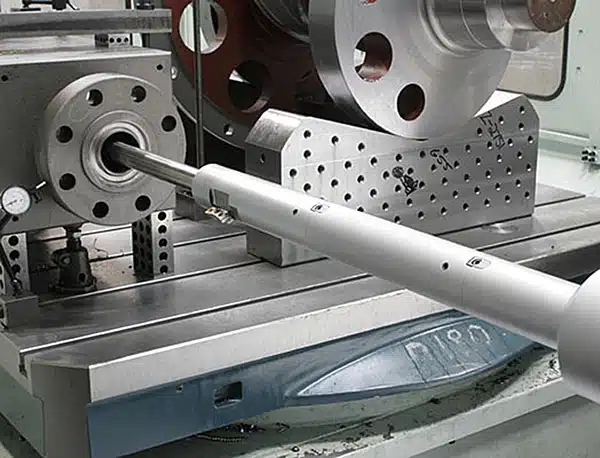

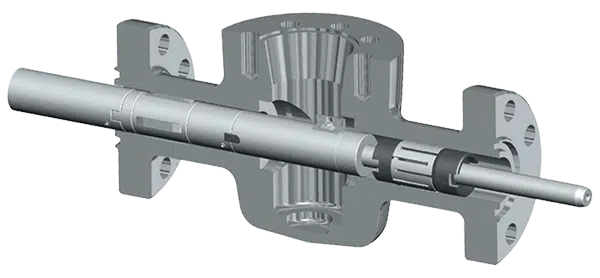

Bottle boring, also known as internal profiling or chamber boring is a special cutting operation where the boring tool expands and contracts within an existing bore to produce a contour inside the workpiece. This enables the manufacturer to machine complex internal shapes, sophisticated bore transitions and undercuts, that reduces the overall weight of critical components without compromising surface integrity. These characteristics are generally too deep or too complicated for single point boring bars. The internal hole profile is larger within the part than at the entry or exit diameters, therefore CNC controls are necessary for coordinating multiple axes simultaneously to create the desired profiles.

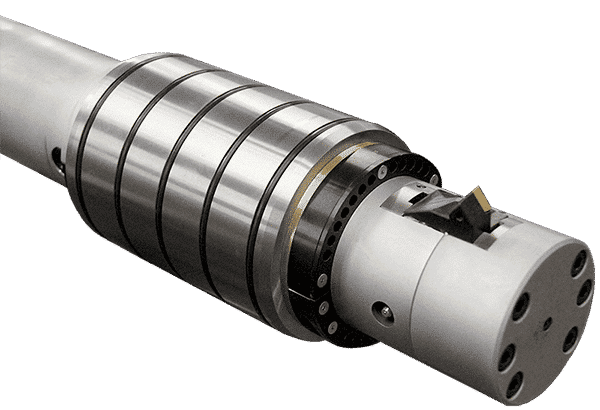

The Cogsdill MBT tool is supported with a proven pilot system, either utilising a rotating O’ring pilot assembly, designed to keep coolant and chips away from the tool body or via coated carbide wear pads, both styles ensuring a vibration free operation, with superior surface finishes. These pads/pilots are designed to suffer the least amount of wear whilst not damaging the base material of the component.

Swarf removal presents a tough challenge when bottle boring. If machining a through hole, the swarf can simply be flushed out of the hole by the workpiece spindle through coolant system. However, in the case of blind holes, and especially with the machining of materials such as nickel based alloys or titanium, the swarf needs to be broken up using high pressure coolant directly onto the insert and through suitable channels.

The Cogsdill Bottle boring tools are designed to use ISO inserts within cartridges or directly fitted into the toolslide. Therefore, depending on the materials to be machined the customer has the flexibitly to use the latest technology and grades of inserts.

The ZX Bottle boring tools are generally used on HBM Machines where the components are too large to be machined on a lathe, however these tools can also be adapted to suit Deep-Hole-Drilling machines, Mill turn machines and Horizontal and Vertical lathes to produce internal extended reach cavities, seat pockets and bottle shaped contours including roughing and finishing operations in one set-up.

Simple connectivity

Extension Coupling

Modular design and construction: Makes adjustment of length and configuration fast and easy, greatly enhancing the versatility of the tool.

Some sizes can be converted for extended-reach applications with piloted support.

Application: valve body

Bottle boring tool inside cavity

Application: valve body

Recessing inside pump housing

Machining seat pocket

Sizing Guide

| COLLET SIZE (øF) | MBT50 | MBT75 | MBT100 | MBT125 | |||||

| 2.060” | 52.32mm | 2.050”–2.130” | 52.07–54.10 mm | ||||||

| 2.560” | 65.02mm | 2.550”–2.630” | 64.77–66.80 mm | ||||||

| 3.000” | 76.20mm | 2.990”–3.070” | 75.95–77.98mm | ||||||

| 4.060” | 103.12mm | 4.050”–3.070” | 102.87–106.43mm | 4.050”–4.190” | 102.87–106.43mm | ||||

| 5.125” | 130.18mm | 5.110”–5.250” | 129.79–133.35mm | 5.110”–5.250” | 129.79–133.35mm | 5.110”–5.250” | 129.79–133.35mm | ||

| 6.375” | 161.93mm | 6.360”–6.500” | 161.54–165.10mm | 6.360”–6.500” | 161.54–165.10mm | ||||

| 7.060” | 179.32mm | 7.050”–7.130” | 179.07–181.10mm | ||||||

| TOOLSLIDE SLIDE RADIUS |

CARTRIDGE CUT RADIUS | ||||||||

| 16.5mm | 21.0mm | 23.0mm | 35.5mm | 23.0mm | 35.5mm | 27.0mm | 44.0mm | ||

| 8.5mm | 50.0–96.0mm | 59.0–105.0mm | |||||||

| 15.0mm | 63.0–109.0mm | 72.0–118.0mm | |||||||

| 14.5mm | |||||||||

| 27.0mm | 75.0–139.0mm | 100.0–164.0mm | |||||||

| 39.5mm | 100.0–164.0mm | 125.0–189.0mm | 100.0–190.0mm | 125.0–215.0mm | |||||

| 56.5mm | 125.0–189.0mm | 150.0–214.0mm | 125.0–215.0mm | 150.0–240.0mm | |||||

| 35.5mm | 159.0–249.0mm | 184.0–274.0mm | 125.0–233.0mm | 159.0–267.0mm | |||||

| 52.5mm | 159.0–267.0mm | ||||||||

| 62.0mm | 178.0–286.0mm | 212.0–320.0mm | |||||||

| L6 | 325mm | 448mm | 608mm | 325mm | |||||

| L7 | 846mm | 1070mm | 1263mm | 846mm | |||||