Versatile Burnishing

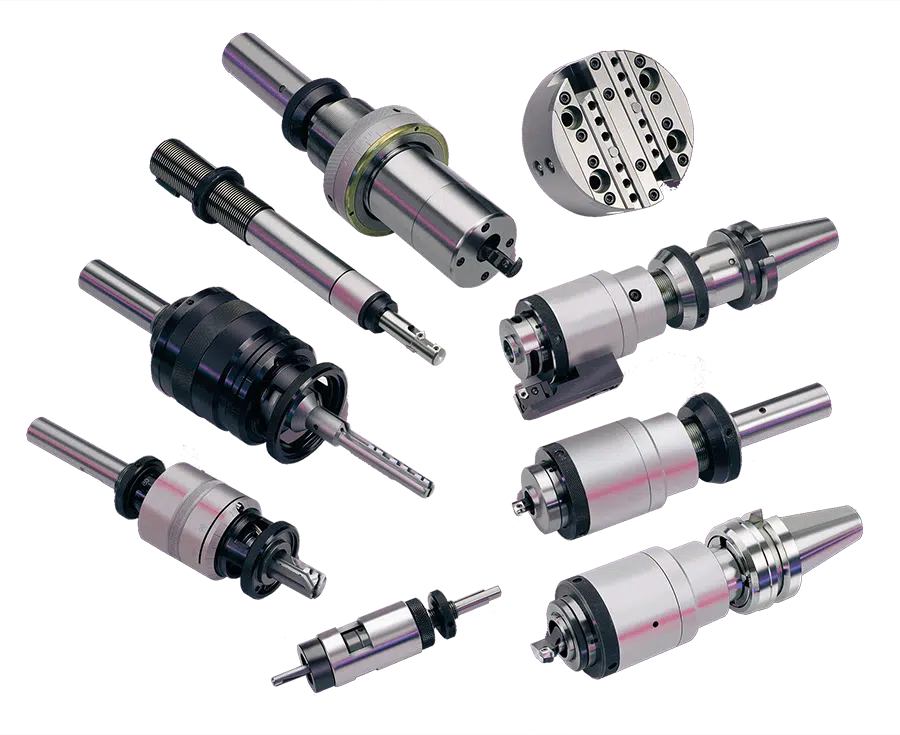

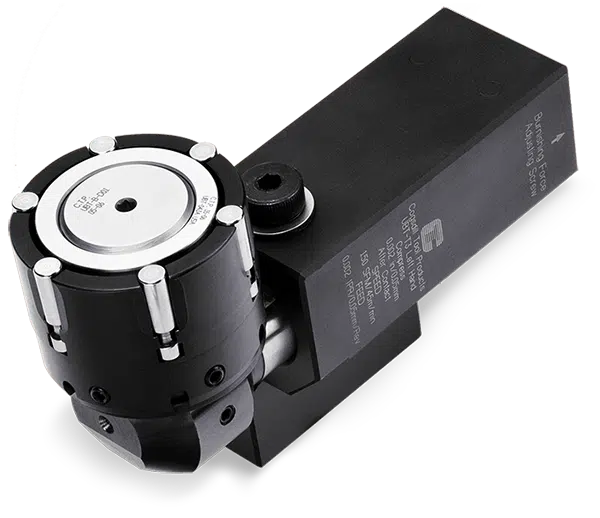

Cogsdill Universal Burnishing Tools are designed for burnishing shafts, faces, tapers, contours, and relatively large IDs (greater than 2.750 inches/69.85mm).

- Boring-Bar style and Index-able turning-holder style designs

- Turning-Holder styles available with force gauges.

- Tool designs to suit any part size or configuration, or any turning machine

- Low surface finishes

- Standard, available off-the-shelf

- Adjustable for optimum burnishing pressure

- Hardened steel or carbide rollers

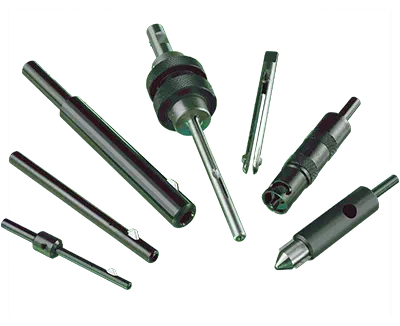

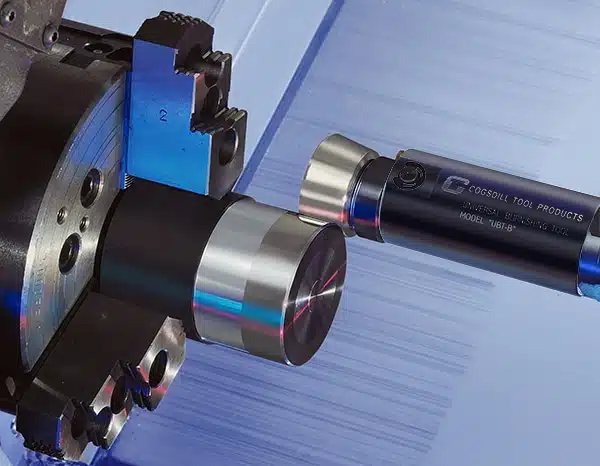

Boring-Bar Style

The Cogsdill UBT-B series are designed for use in a machine turret configuration on a CNC lathe, where differing diameters are required from a single tool set-up.

Three basic styles are available:

- UBT-B1 (For large diameters, tapers & faces)

- UBT-B2 (For smaller diameters, tapers & faces)

- UBT-B3 (For smaller diameters where facing is not required)

Both UBT-B1 and UBT-B2 are offered with both a hardened steel roll and a carbide roll, where as UBT-B3 is offered with a hardened steel roll only.

Boring-Bar style tool operation:

- Mount any UBT-B tool in the desired boring bar station. (Note: The red orientation spot must be opposite the contact point.)

- Bring the tool into contact with the part to be burnished.

- Feed the tool another 0.003-0.005 inch (0.08-0.13mm) into the part to provide interference between the roll and part so that the roll will float in its spring travel.

- Interference should not be used to increase burnishing force; burnishing force should only be adjusted with the load adjusting screws. This ensures the tool can be fed on/off the part and across interruptions without damage to the tool or workpiece.

- For optimum results and long tool life, coolant is required. Any soluble, synthetic, or straight oil can be used.

- Whenever possible, and for best results, the tool should be fed towards the spindle when burnishing diameters and towards the centerline when burnishing faces. (Note: the UBT-B3 tool cannot be used to burnish faces.)

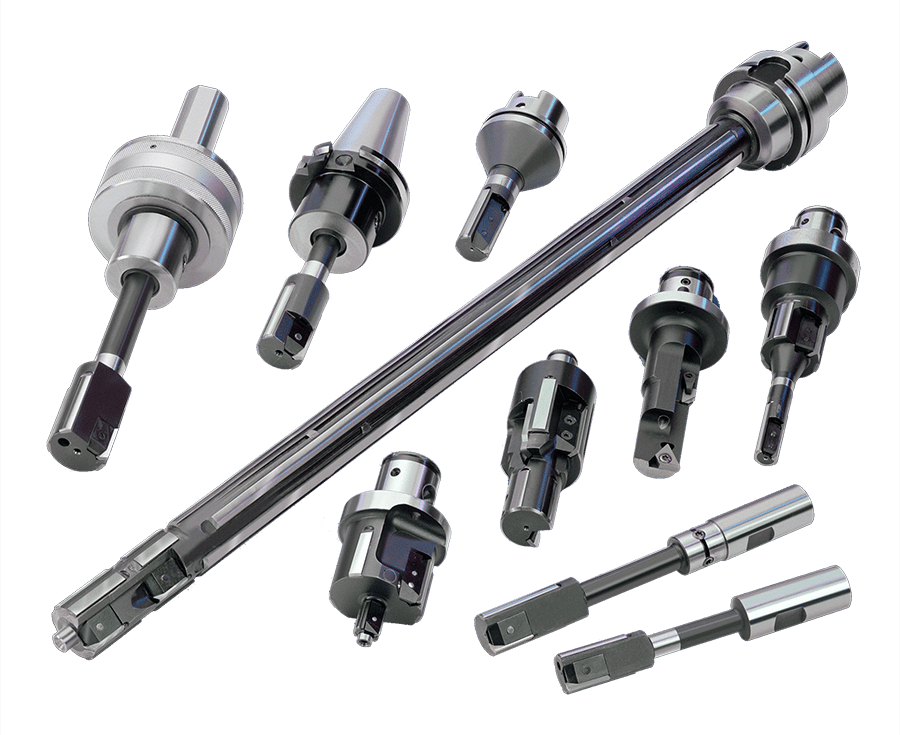

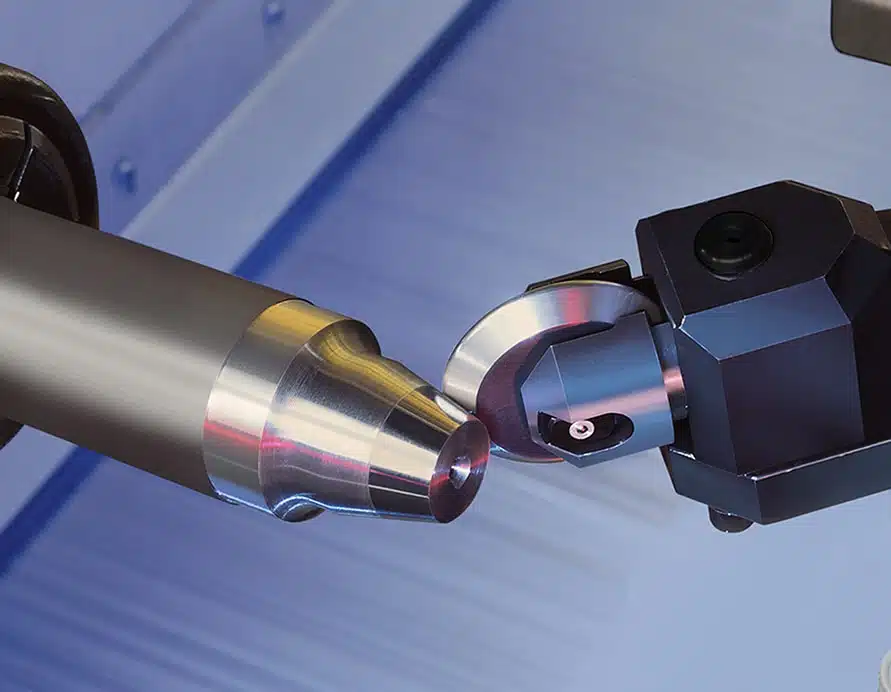

Turning-Holder Style

The Cogsdill UBT-T series are designed for use in an indexable turning holder configuration, mounted to a machine turret on a lathe.

Four basic styles are available in both left-hand and right-hand versions.

- UBT-T1 (For outside diameters, faces, tapers and contours)

- UBT-T2 (For outside diameters only)

- UBT-T3 (For large outside diameters only)

- UBT-T4 (For outside diameters where limited space is available)

The UBT-T1 and UBT-T2 are offered with a carbide roll as standard. The UBT-T3 and UBT-T4 are offered with a hardened steel roll only. A force gauge option is available on the UBT-T2 and UBT-T3.

Turning Holder style tool operation:

- Mount any UBT-T tool in the desired turning station. Use a UBT-T tool that corresponds with the respective turning tool.

- Bring the tool into contact with the part to be burnished; contact has occurred when you see the mandrel rotating.

- Feed the tool another 0.003-0.005 inch (0.08-0.13mm) into the part to provide interference between the roll and part so that the roll will float in its spring travel.

- Interference should not be used to increase burnishing force; burnishing force should only be adjusted with the load adjusting screws. This ensures the tool can be fed on/off the part and across interruptions without damage to the tool or workpiece.

- For optimum results and long tool life, coolant is required. Any soluble, synthetic, or straight oil can be used.

- Whenever possible, and for best results, the tool should be fed towards the spindle when burnishing diameters and towards the centerline when burnishing faces.

- Note: UBT-T2 and UBT-T3 tools cannot be used to burnish faces.

Adaptable Flexibility. Mirror Finishing.

Any size. Any configuration. On any turning machine.

We hold a range of tools and spare Carbide and HSS rolls in stock.

Available for immediate shipping!

UBT-B1

The UBT-B1 Universal Burnishing Tool is for burnishing outside diameters, faces and inside diameters greater than 70mm (2.75 in.).

Standard Tool Specifications

UBT-B2

The Cogsdill UBT-B2 Universal Burnishing tool is a smaller version of the UBT-B1. It is suitable for burnishing outside diameters, faces, and inside diameters greater than 39.6mm (1.56 in.).

Standard Tool Specifications

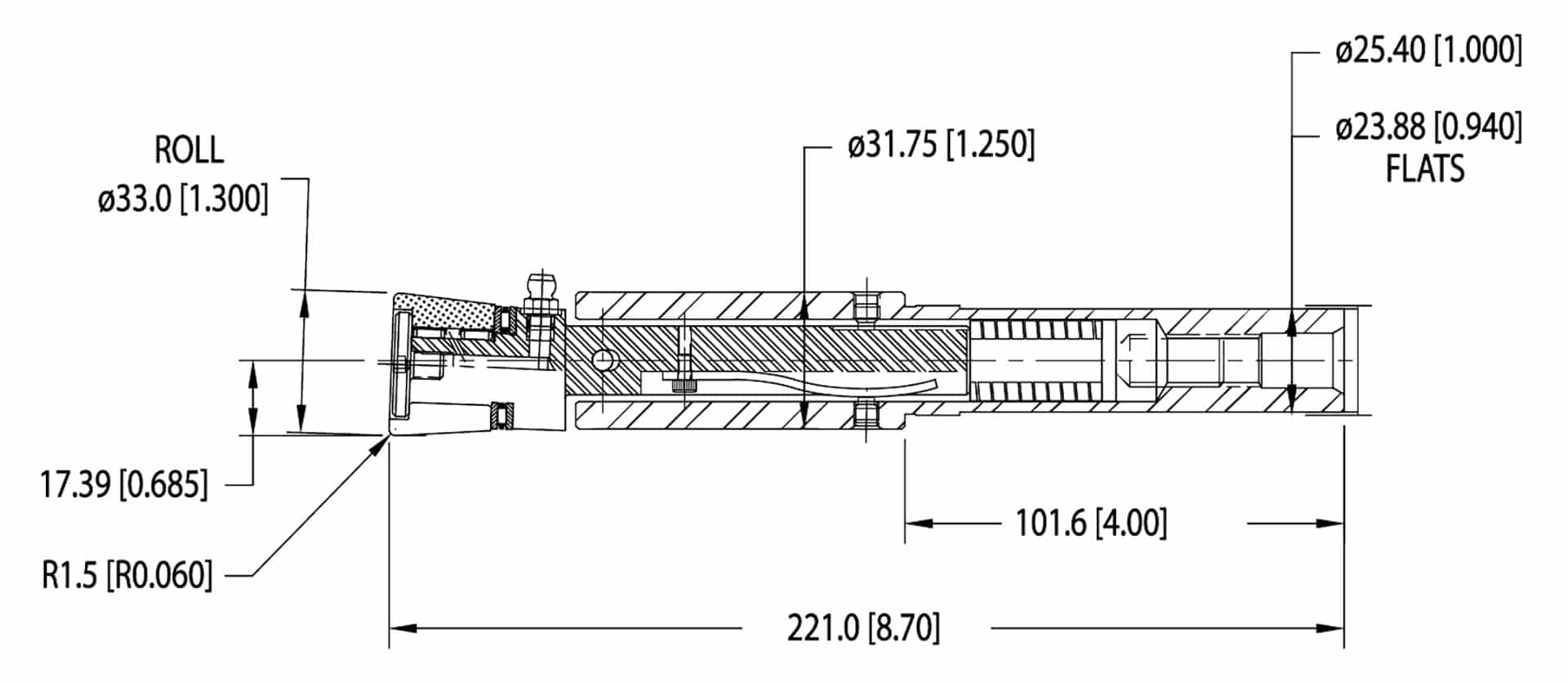

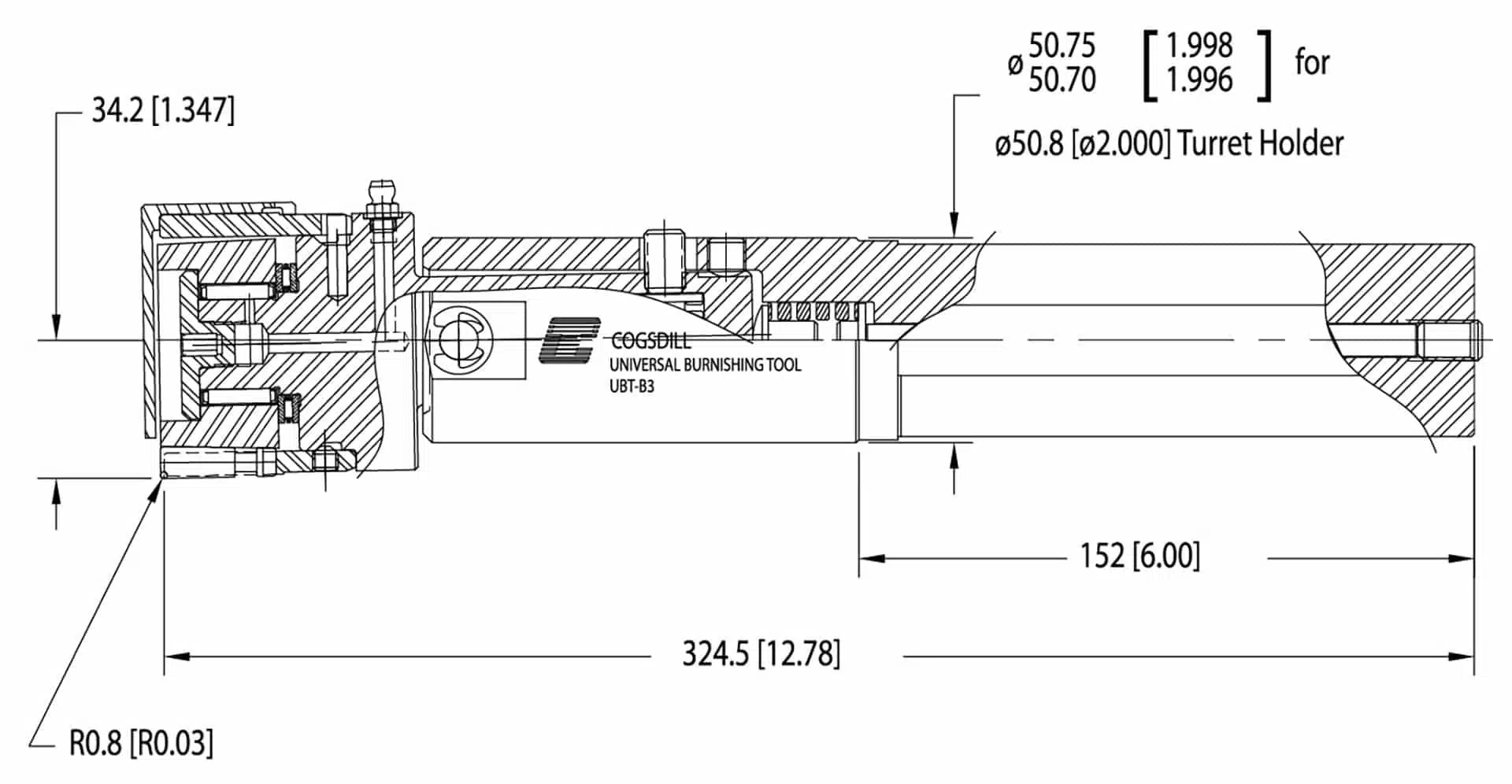

UBT-B3

The Cogsdill UBT-B3 Universal Burnishing Tool is for use in smaller inside diameters greater than 70mm(2.75 in.) or on large outside diameters greater than 100mm (4.00 in.).

Standard Tool Specifications

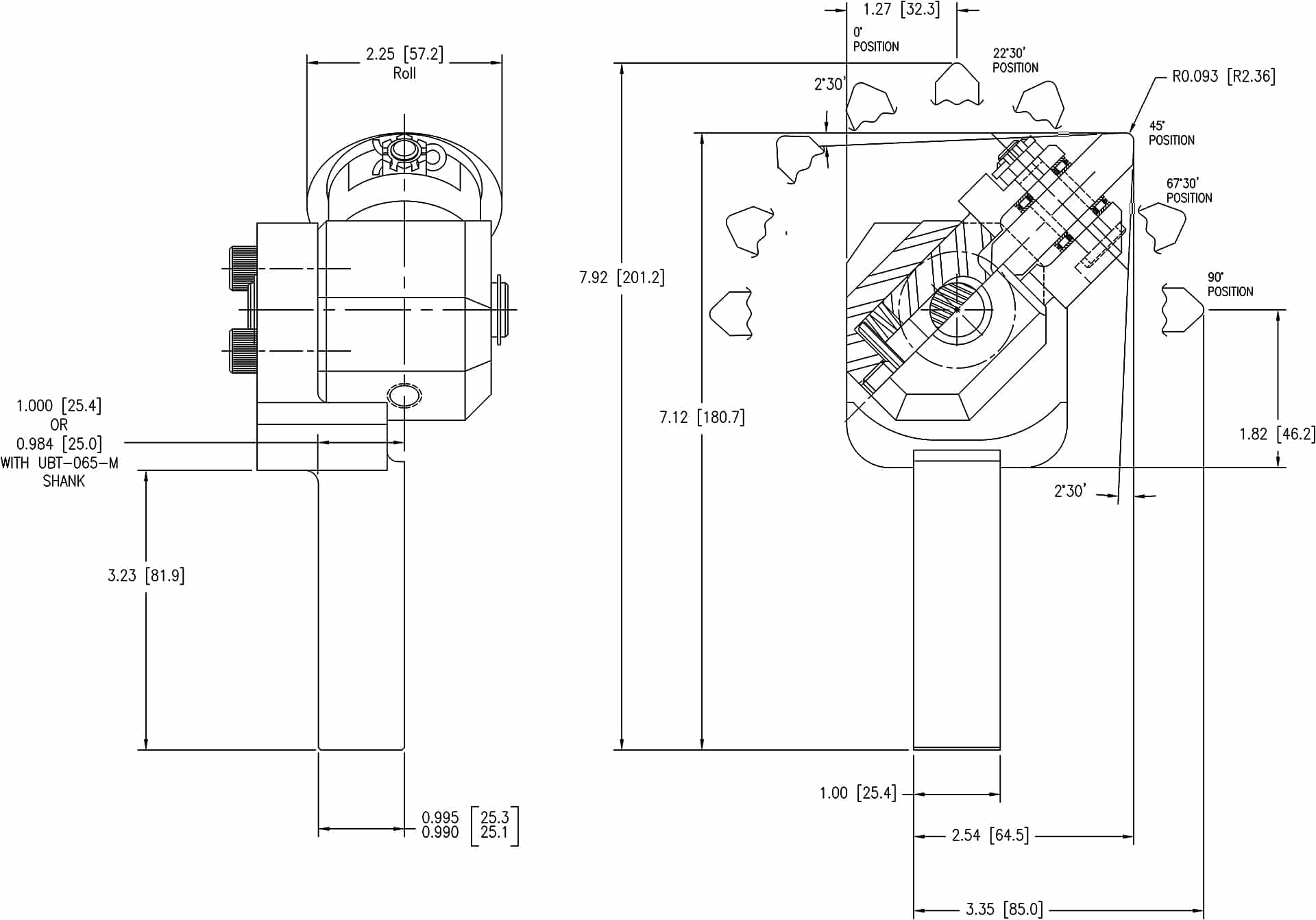

UBT-T1

The Cogsdill UBT-T1 Universal Burnishing Tool is designed for burnishing outside diameters, faces, tapers, and contours.

The new tool eliminates the need for left or right handed configurations, as a single tool now suits both orientations. The UBT-T1 is supplied as standard with a carbide roller.

Standard Tool Specifications

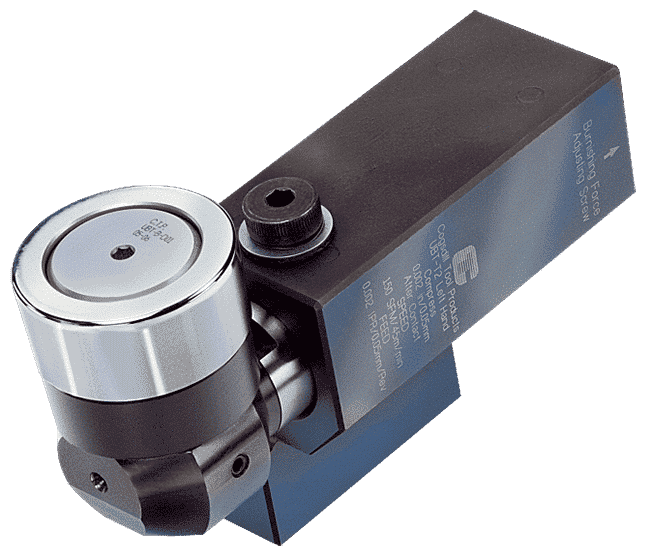

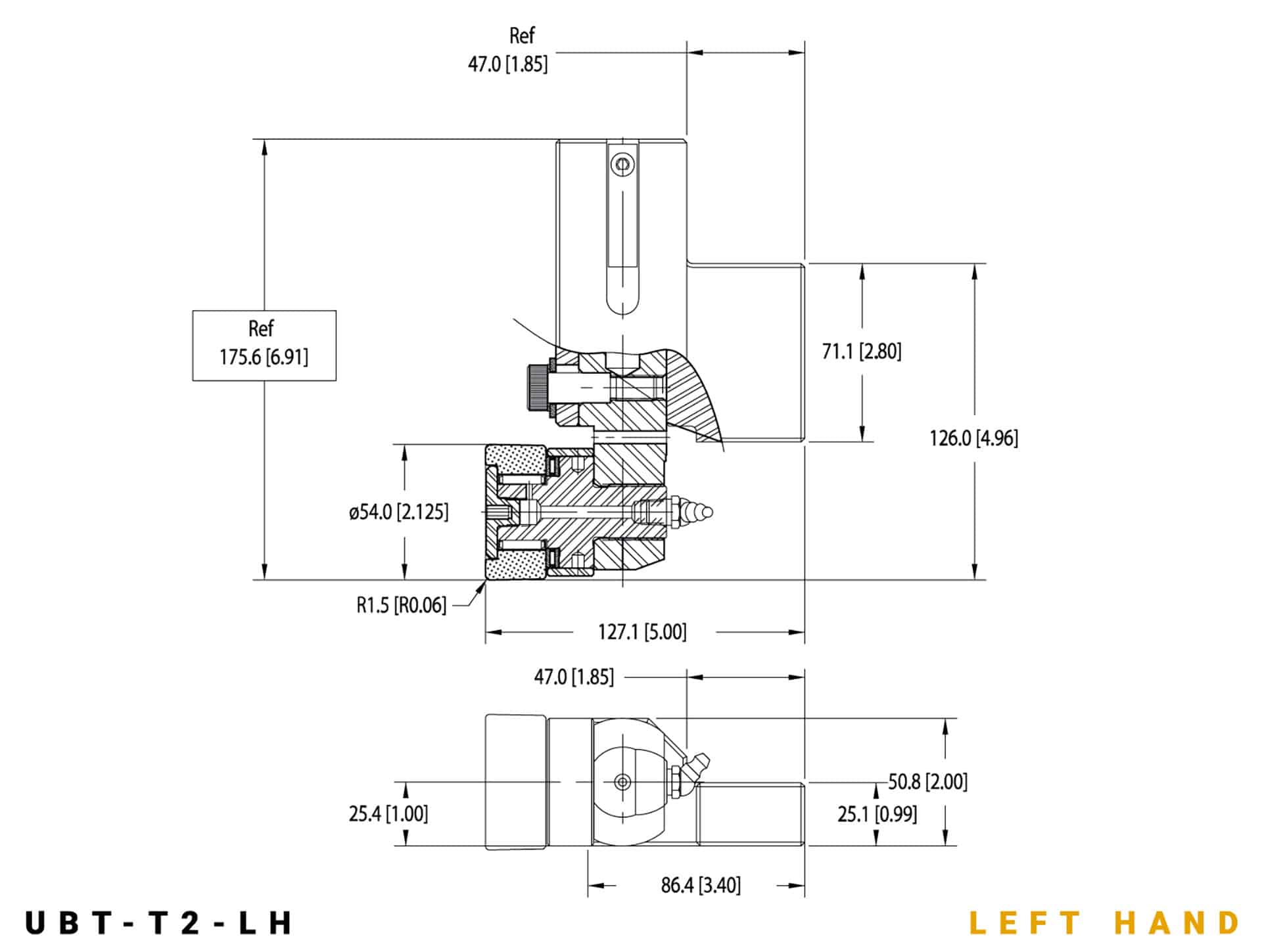

UBT-T2

The Cogsdill UBT-T2 Universal Burnishing Tool is designed for burnishing outside diameters.

The tool comes in both left hand and right hand configurations. The UBT-T2 is offered with both a hardened steel and a carbide roll.

Standard Tool Specifications

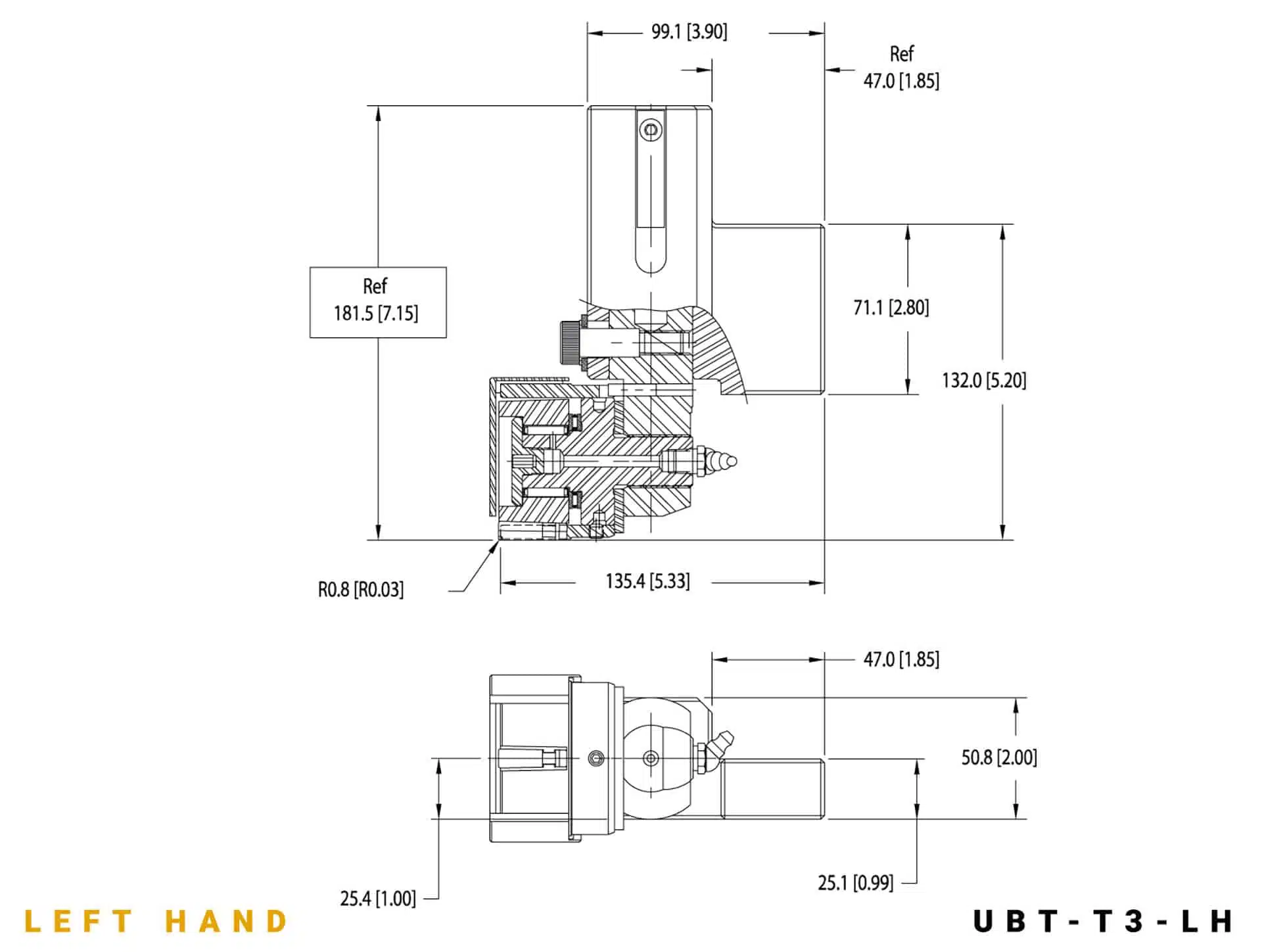

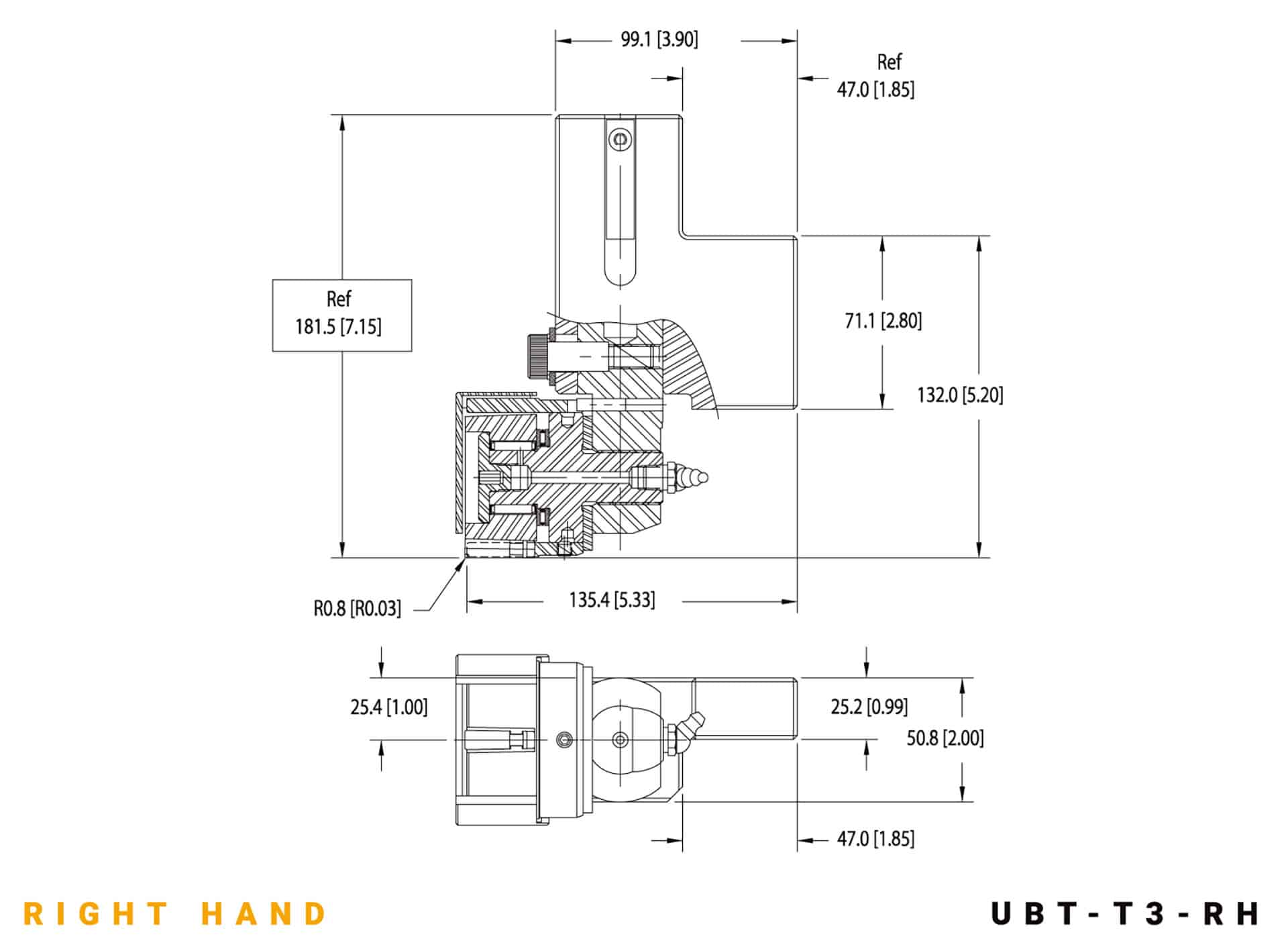

UBT-T3

The Cogsdill UBT-T3 Universal Burnishing Tool is designed for burnishing large outside diameters (greater than 100mm/4in.). The tool comes in both left hand and right hand configurations.

Standard Tool Specifications

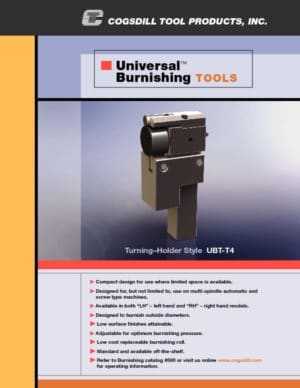

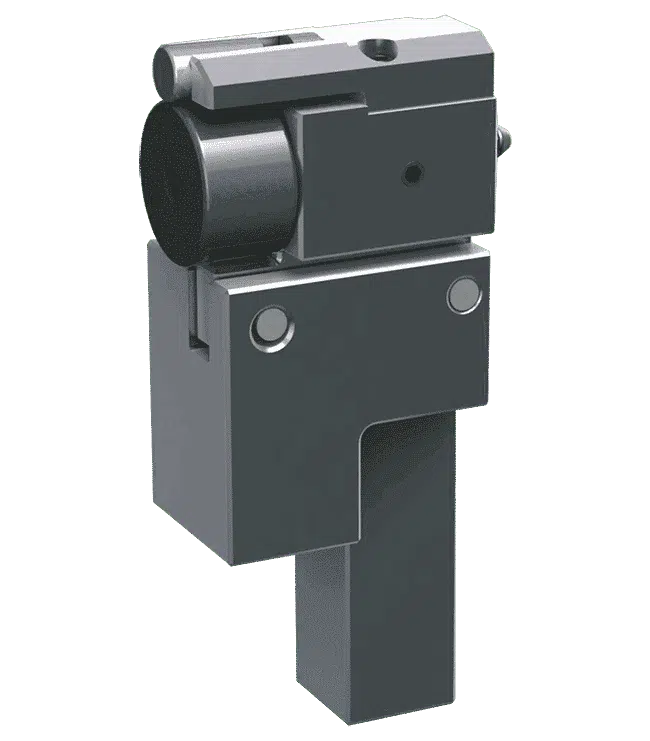

UBT-T4

The Cogsdill UBT-T4 Universal Burnishing Tool is a compact design for use where limited space is available.

- Designed for, but not limited to, use on multi-spindle automatic and screw type machines.

- Available in both “LH” – left hand and “RH” – right hand models.

- Designed to burnish outside diameters.

- Low surface finishes attainable.

- Adjustable for optimum burnishing pressure.

- Low cost replaceable burnishing roll.

- Standard and available off-the-shelf.

Standard Tool Specifications