Recessing Tools

Cogsdill offers the widest array of standard tooling and the broadest range of solutions for precision grooving, recessing, and internal and external facing and chamfering.

We will design and manufacture a complete tooling package for your application, including Automatic Recessing heads, cutters and pilots. The wide variety of standard recessing heads described in this catalog are available from stock to suit most applications and machines. Special recessing heads can be designed and manufactured for unusual applications.

Greater accuracy.

Shorter cycle time.

Lower cost.

Shorter cycle time.

Lower cost.

Cogsdill Automatic Recessing Tools will save you time and money. Cycle time is reduced from minutes or hours to seconds. The precision is built into the head so that grooves and recesses can be machined with exceptional accuracy and repeatability. The Automatic Recessing head changes the operational direction by 90˚ (i.e., axial spindle motion is converted to radial cutter movement). Recessing operations can be performed on a variety of machines, even on a drill press.

Superior Craftsmanship

All moving parts in our recessing heads are hardened and precision ground to ensure lasting accuracy and low maintenance costs. Close tolerances virtually eliminate “backlash” during retraction, for accurate size on groove width as well as depth. All sliding surfaces have large, hardened, load-bearing areas for long life and durability.

Superior Construction

Compression of the head between the machine spindle and the workpiece or jig plate actuates a sliding inclined wedge mechanism, thereby extending the cutter. Groove depth can be machined with great accuracy.

The cutter retracts radially prior to axial withdrawal of the tool from the bore, for accurate control of groove width. This design also results in a constant linear relationship between spindle movement and cutter movement. The straight-line movement of the cutter makes cutter regrinding easier.

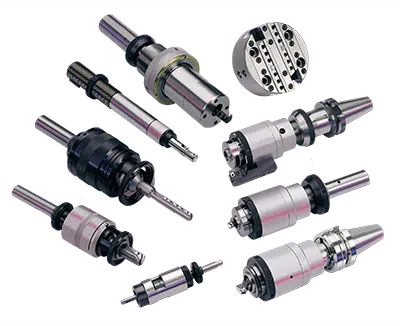

AR Series

Automatic recessing tools, for machining precision internal and external grooves and recesses on virtually any type of machine. The AR Series Automatic Recessing Tool is made up of three basic components: head, cutter, and pilot. The head is usually standard and consists of shank and tool body. All cutters and pilots are manufactured to suit your application.

Features

- Pilots off workpiece or jig plate

- Micrometer stop controls depth of cut

- Tool adjustment controls axial location

- Through-shank coolant is standard

- Overtravel shanks are standard

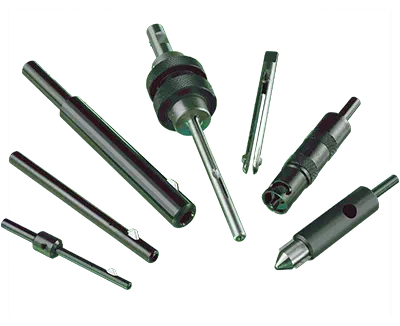

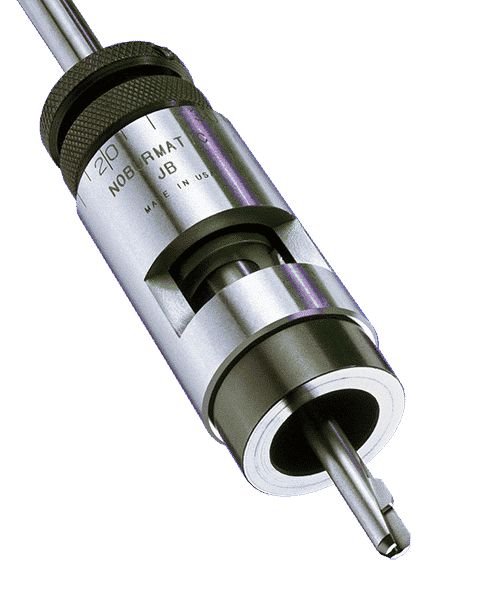

Nobur JA Series

The Nobur JA Series of recessing heads are for deep bore recessing and grooving. These tools can be used on drill presses, jig boring machines, milling machines, tool or turret lathes, horizontal boring machines, CNC machines, and special purpose machines.

Features:

- In-bore pilot supports cutter along its entire length – eliminates tool deflection; ensures concentricity through rigid cutting action

- Micrometer-stop adjustment

- Multiple grooves, chamfers, or metering lands

- O-ring and retaining ring grooves

- Relief grooves and tube sheet grooves

- Back-chamfering and facing of deep bores

Nobur JB Series

For back-chamfering or deburring on drill presses, CNC machines, tool or turret lathes, multi-spindle machines and jig boring machines.

- Consistently accurate back-chamfering, deburring, and back-countersinking operations

- Pilots in hole for precise concentricity

- Rigid support of the cutter virtually eliminates deflection

- Micrometer-stop adjustment

- Standard pilots and cutters for hole sizes from 3/16 to 3/4” (4.75 to 19.05mm)

- Special pilots and cutters available upon request

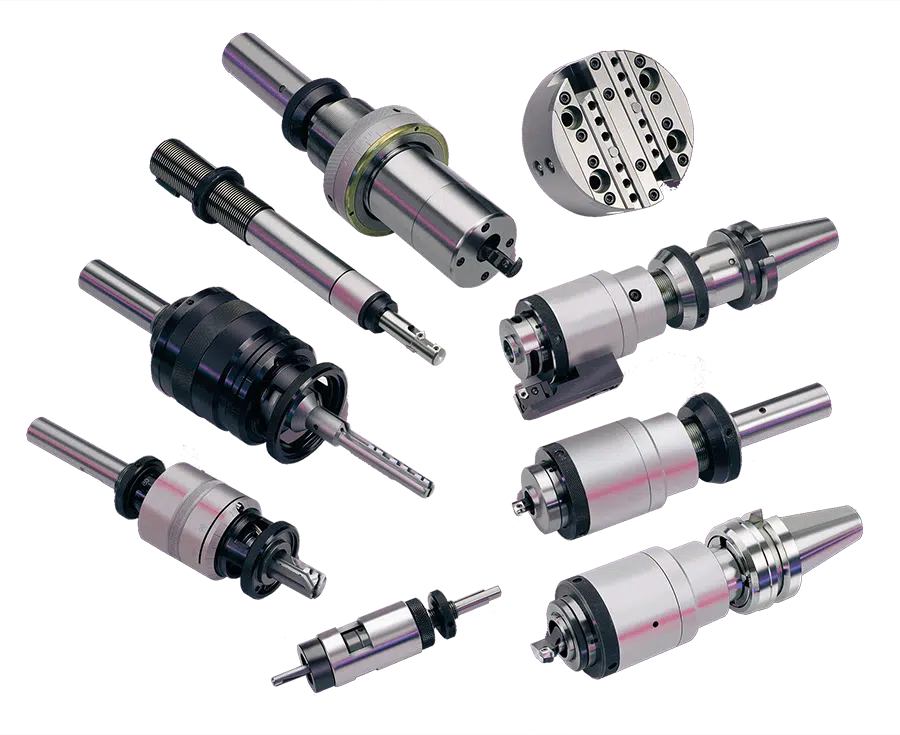

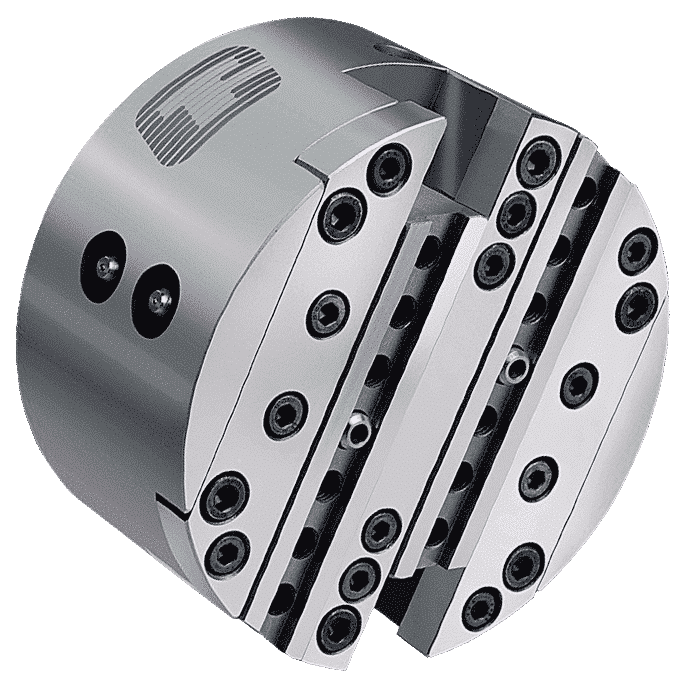

Generating Heads

Cogsdill generating heads are designed to work on machines where the tool slide stroke is controlled by a drawbar. The drawbar can produce finite, accurate movements in the tool slide(s), allowing the head to perform accurate machining operations. Drawbars can either push or pull on the actuator, and may be controlled by CNC, hydraulic, or mechanical action.

Custom-designed top tooling is mounted in qualified holes on the toolslide. Standard inserts are used for most applications. Special head designs and special form cutters are available.

Operations such as boring, turning, facing, chamfering, and form cutting can be easily performed. Generating heads can often be made to perform multiple operations in a single pass – this provides for optimum efficiency and performance in your machining operations.