Deep into the groove

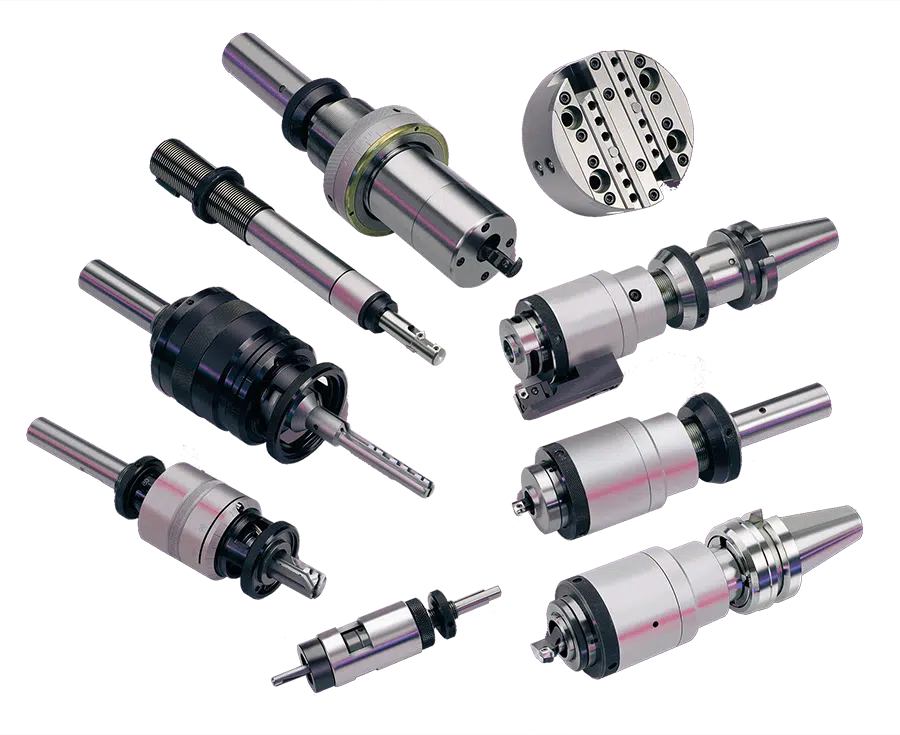

The Nobur JA Series of recessing heads are for deep bore recessing and grooving. These tools can be used on drill presses, jig boring machines, milling machines, tool or turret lathes, horizontal boring machines, CNC machines, and special purpose machines.

For heavy duty applications, please see the JA2000 with internal coolant capability.

Features:

- In-bore pilot supports cutter along its entire length – eliminates tool deflection; ensures concentricity through rigid cutting action

- Micrometer-stop adjustment

- Multiple grooves, chamfers, or metering lands

- O-ring and retaining ring grooves

- Relief grooves and tube sheet grooves

- Back-chamfering and facing of deep bores

How Nobur JA Series tools work:

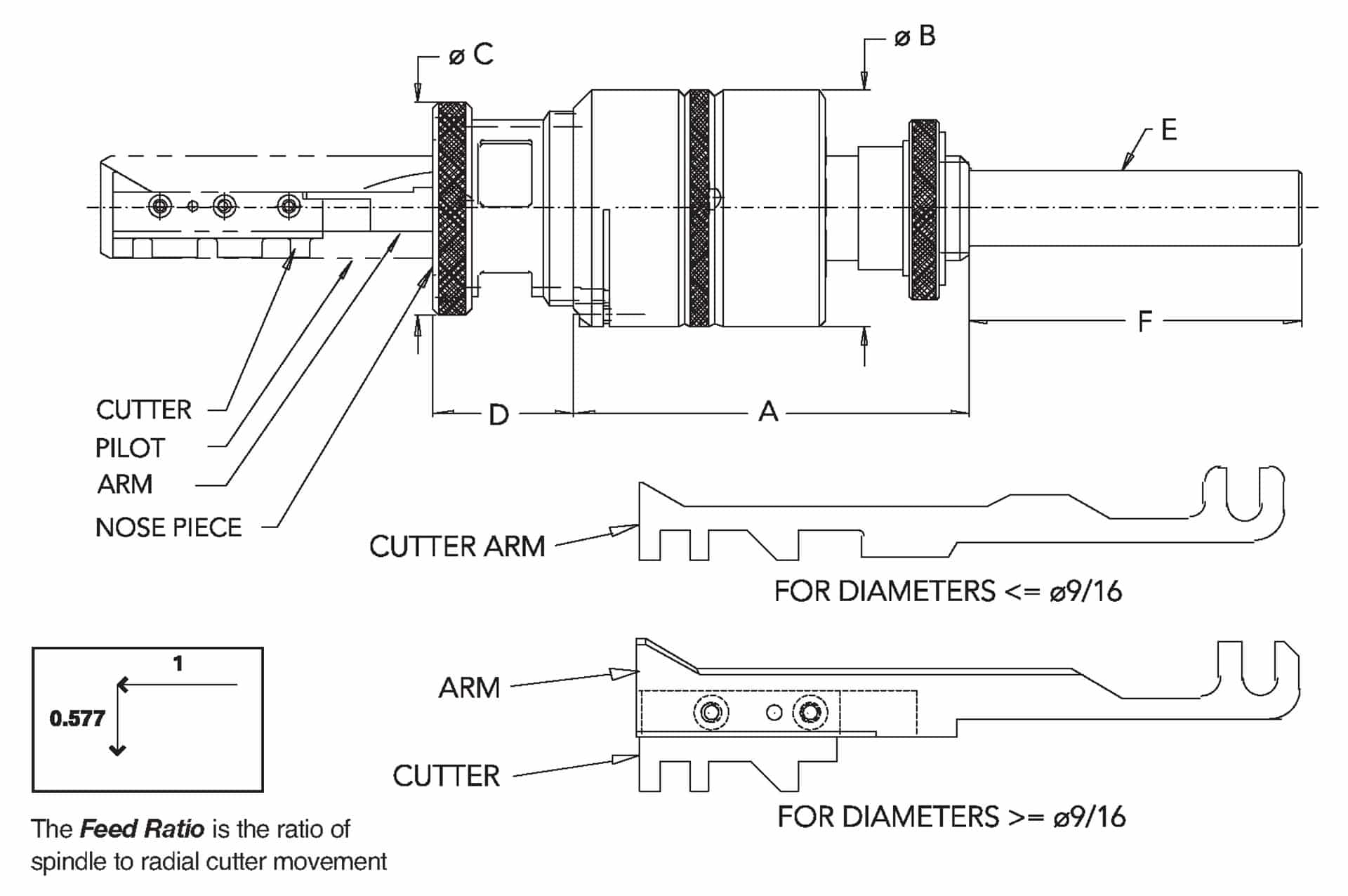

| 1 | Approach Stroke: The Nobur JA tool is rotating in a machine spindle. The spindle is lowered. The tool approaches entry into the bore. |

| 2 | Feed Stroke: The pilot is located in the bore, stopping against the face of the workpiece. Downward travel of the machine spindle compresses the tool so that the cutter feeds out radially into the surface of the workpiece. The pilot rigidly supports the cutter along its entire length to eliminate deflection and ensure concentricity. |

| 3 | End of Feed Stroke: Radial depth of cut is obtained when the micrometer-stop nut bottoms out. Groove location is controlled by the adjusting stop-collar, which moves the nose-piece up or down to position the cutter arm for accurate groove location. |

Nobur JA 2000

Designed for heavier cuts than the regular JA. Innovative internal coolant system directs coolant to cutting edges for improved chip evacuation, longer tool life, better tool function, and improved repeatability. For use on machines with internal coolant capability.

JA2000 recessing heads can be ordered in a side-port model for use on machines that do not have through-spindle coolant capability. Through-shank coolant is standard; specify side-port coolant if desired.

Features:

- Same in-bore pilot support and micrometer-stop adjustment as the regular JA

- Capable of wider cuts than the regular JA in some applications

- Extremely durable high-load precision dual bearings for long life

- Easy disassembly and reassembly for maintenance

- Overtravel units available upon request

Standard Tool Specifications

| HEAD | CAPACITY 1 | (A) | (B) | (C) | (D) | (D) | (E) | (F) | |||||||

| TYPE | FREE | MAXIMUM | MINIMUM | SHANKS 2 | |||||||||||

| in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | ||

| JA | 0.25 | 6.30 | 3.82 | 97.00 | 2.28 | 57.90 | 2.06 | 52.30 | 2.24 | 56.90 | 1.24 | 31.50 | 3/4″ straight 3 | 3.25 | 82.60 |

| 1.85 | 47.10 | 1″-12 acme | 3.63 | 92.20 | |||||||||||

| 1-1/16″-12 acme | 3.63 | 92.20 | |||||||||||||

| #2 morse taper | 3.19 | 81.00 | |||||||||||||

| #3 morse taper | 3.88 | 98.60 | |||||||||||||

| JA2000 | 0.25 | 6.30 | 4.43 | 112.5 | 3.36 | 85.40 | 3.00 | 76.20 | 1.53 | 38.9 | 1.03 | 26.20 | 1″ straight 4 | 3.00 | 76.20 |

| 1.85 | 47.10 | ||||||||||||||

1 Capacity means the suggested maximum groove diameter. Dependent upon cutting forces and bore diameter. Stated capacity is for steel.

2 Shank is included with head. Shanks other than shown can be supplied upon request.

3 Supplied with through-tool coolant.

4 Through-shank coolant is standard; specify side-port coolant if desired.