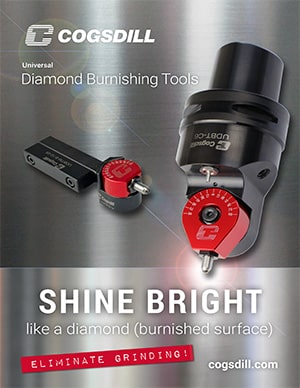

Diamond Hard

The Cogsdill Diamond Burnishing Tools are designed to produce high quality, low micro-inch burnished finishes on shafts, large bores, and faces. With most metals, a turned or ground part with a properly prepared 40 to 60 micro-inch (1.02 to 1.54 µm) finish can be burnished to a 4 to 8 micro-inch (0.10 to 0.20 µm) finish in seconds. Cast iron can usually be burnished to an 8 to 15 micro-inch (0.20 to 0.38 µm) finish.

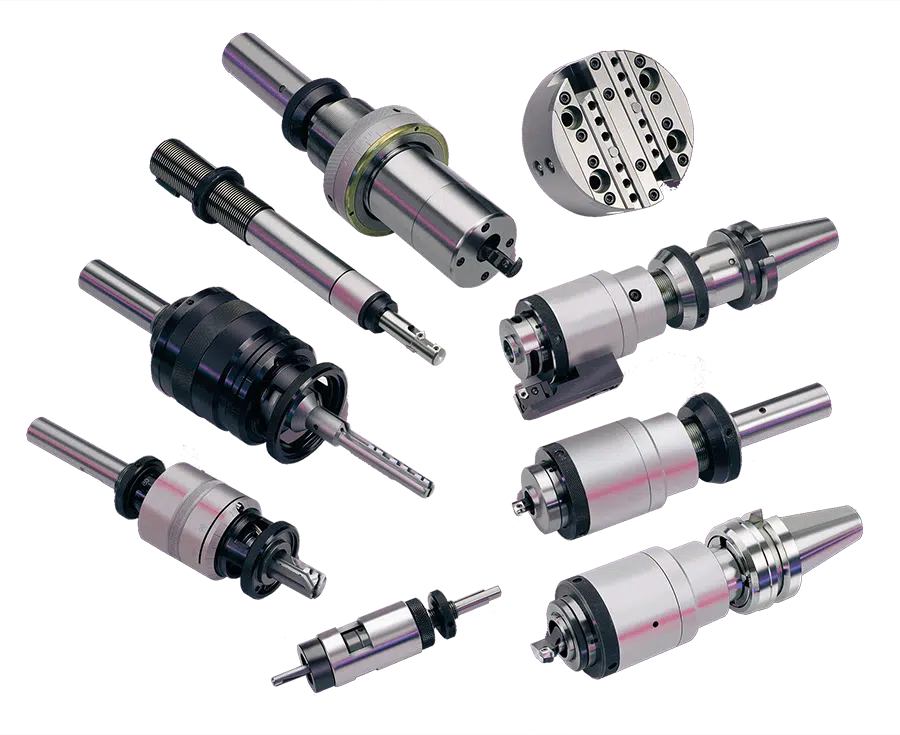

- Multiple designs for use on most turning and Swiss-type machines – manual or CNC

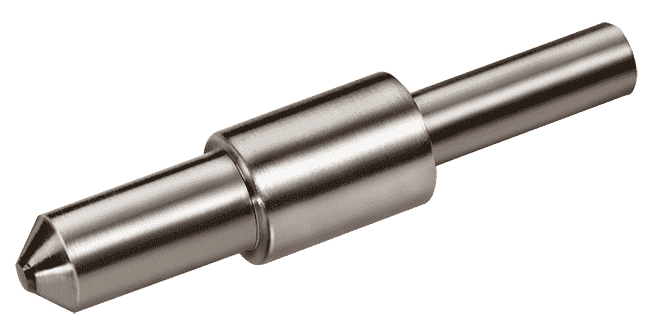

- All tools have include a premium quality, replaceable and polished diamond insert

- Easily adjustable for optimum burnishing pressure

Simple and efficient, Cogsdill Diamond Burnishing Tools are designed to produce mirror-like finishes on any size stock; from carbon steels to tool steels, cast iron to alloys, and most ferrous and non-ferrous metals.

Simple and Versatile

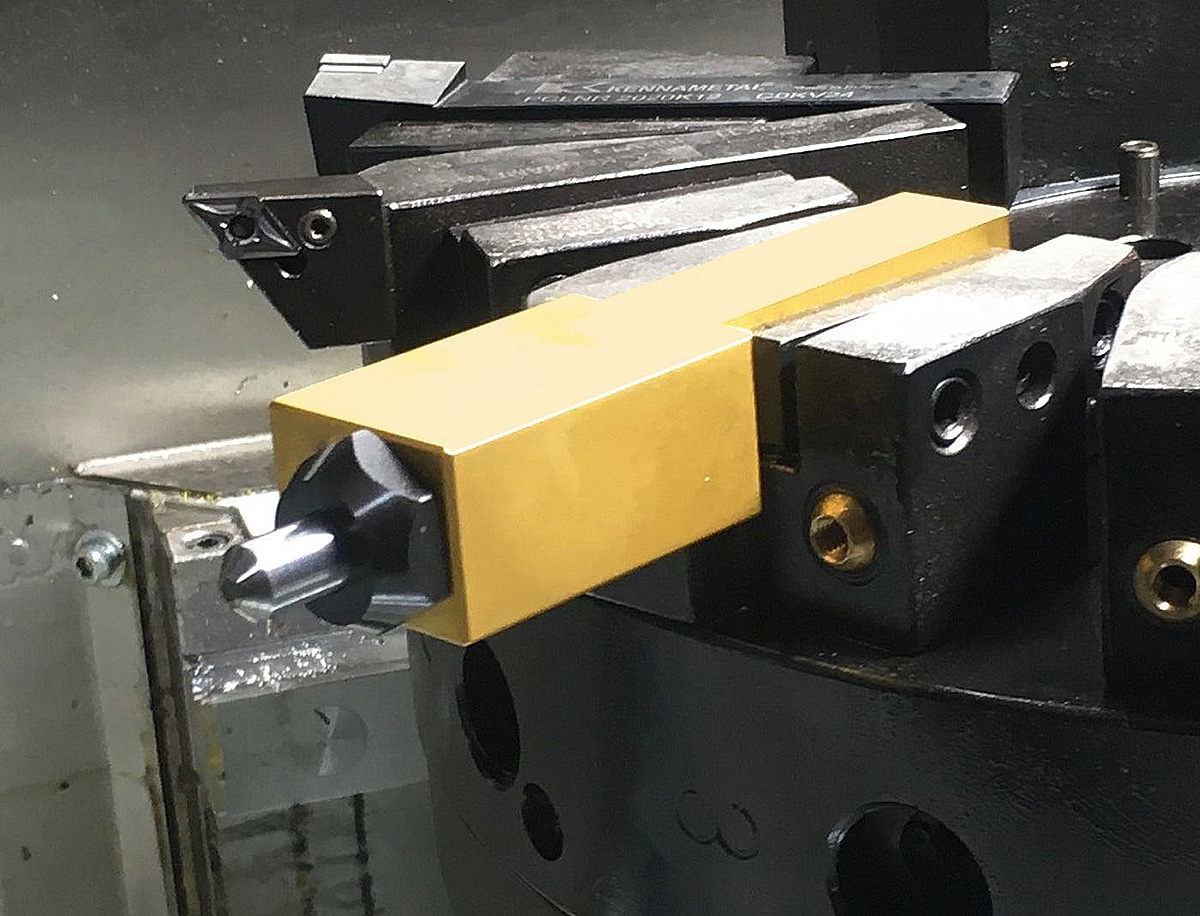

Since set up and operation is relatively simple, no special operator skills are required. Diamond Burnishing Tools are versatile; various models are designed for use in the tool post of a manual lathe, automatic, or in CNC equipment. The tools can be used on both large and small diameters, and are ideal for short production runs.The Diamond Burnishing Tool can produce quality finishes on interrupted surfaces, such as a shaft with a keyway or the face of a flange having a series of bolt holes.

While the tool must be used with coolant, no special coolant is required. Straight oils, soluble oils, and synthetic coolants can be used to provide the necessary lubrication.

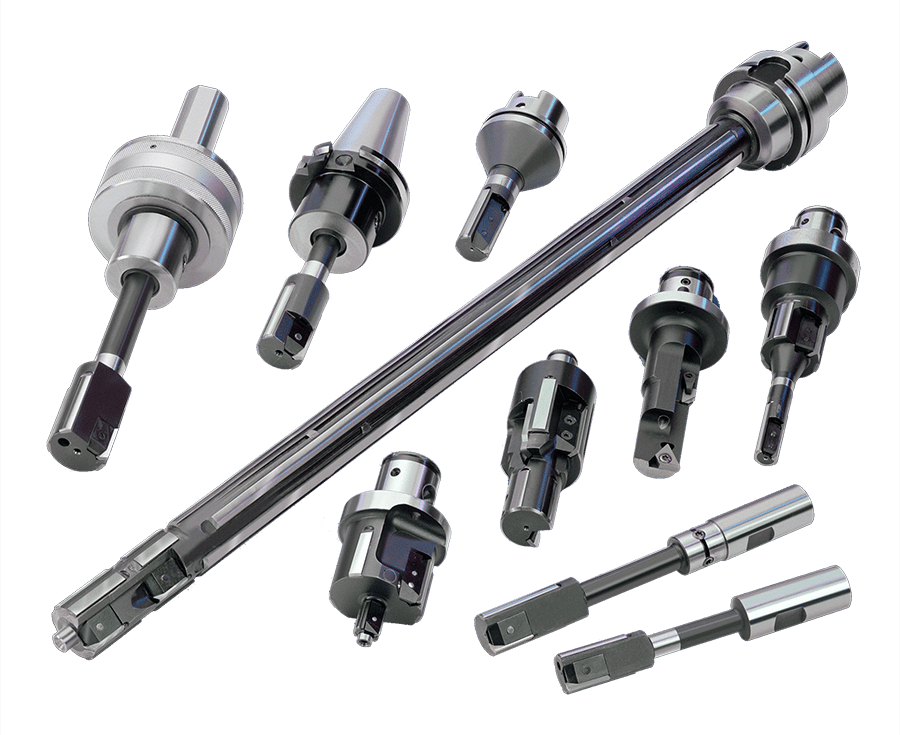

The Diamond Burnishing Range

Conventional Turning Machine / Lathe

Swiss-Type Machine / Mini Series

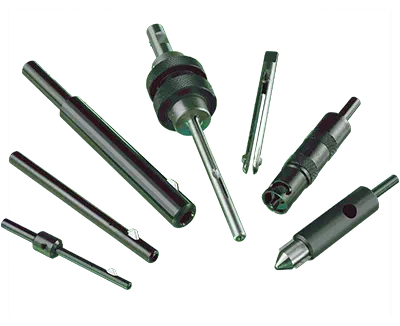

DB Series

Turning-Holder style, designed for use in a tool-post in either a manual or a CNC machine.

RDB Series

Round Boring-Bar style, designed for use in turrets in CNC machines.

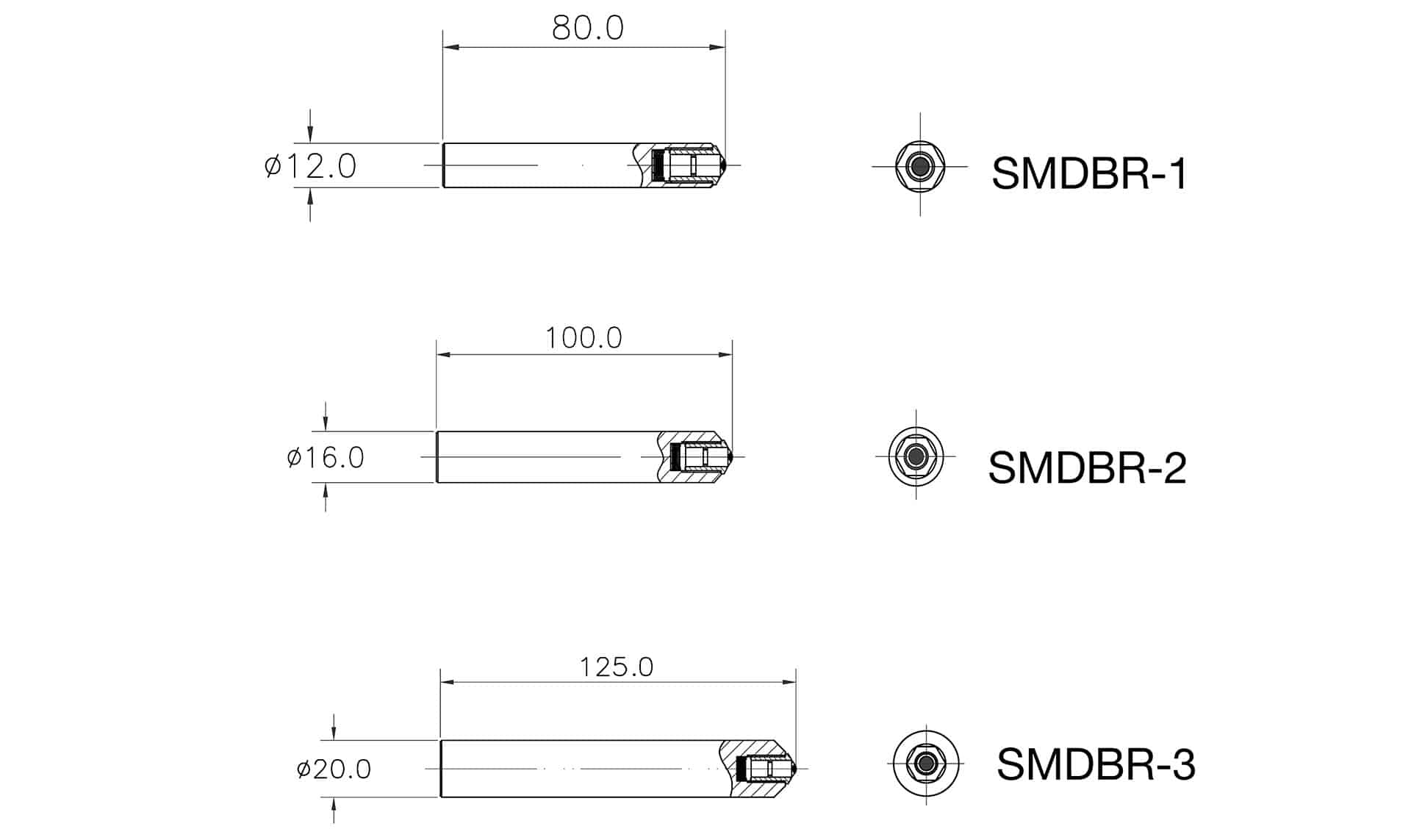

SMDBR Series

Mini round Boring-Bar style, designed for use in turrets in Swiss-Type CNC machines.

SMDB/S Series

Mini Turning-Holder / Square style, designed for use in a tool-post in Swiss-Type CNC machines.

How Diamond Burnishing tools work:

| 1 | The Cogsdill Diamond Burnishing tool is mounted in the tool post or turret of the desired machine. |

| 2 | The diamond burnishing point is brought into contact with the workpiece at the centerline of the part and perpendicular to the surface being finished. |

| 3 | The tool is then fed into the workpiece an additional .002 or .003 inch (.05 or .08mm) to allow the diamond insert to become disengaged from the stop in the holder. |

| 4 | The spring, with its preload, forces the diamond against the workpiece. |

| 5 | The tool is then fed along the surface of the rotating workpiece to produce a mirror-like finish. |

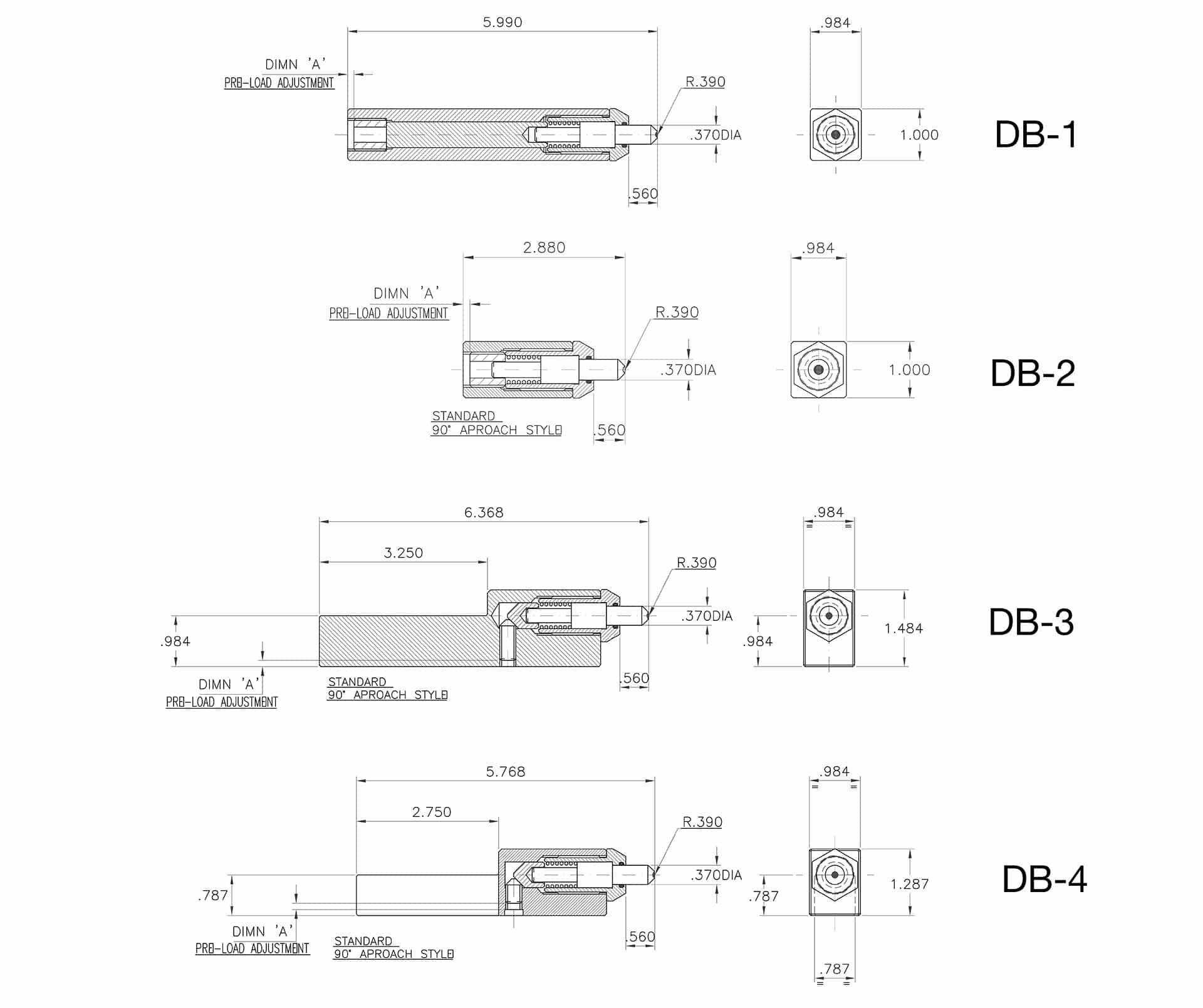

Easily Adjustable

- Diamond Burnishing Tools are adjustable for optimum burnishing pressure.

- For the DB-1 and DB-2 models, the adjustment screw is located in the end of the tool.

- For models DB-3 and DB-4, the adjustment screw is located on the side of the tool.

The premium quality and replaceable diamond burnishing insert is polished and contoured to provide superior finishes and long tool life.

Multiple Designs. Easily Adjustable.

Produce mirror-like finishes on any size stock, including interrupted surfaces.

We hold a range of Diamond Burnishing tools and diamond nibs in stock.

Available for immediate shipping!

Standard Tool Specifications

DB Series Diamond Burnishing Tools

Turning-Holder style, designed for use in a tool-post in either a manual machine or an automatic CNC machine.

RDB Series Diamond Burnishing Tools

Round Boring-Bar style, designed for use in turrets in CNC machines.

SMDBR Series Diamond Burnishing Tools

Mini round Boring-Bar style, designed for use in turrets in Swiss-Type CNC machines.

SMDB Series Diamond Burnishing Tools

Mini Turning-Holder style, designed for use in a tool-post in Swiss-Type CNC machines.

SMDBS Series Diamond Burnishing Tools

Mini Turning-Holder style, designed for use in a tool-post in Swiss-Type CNC machines.