Boring just became interesting

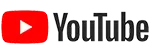

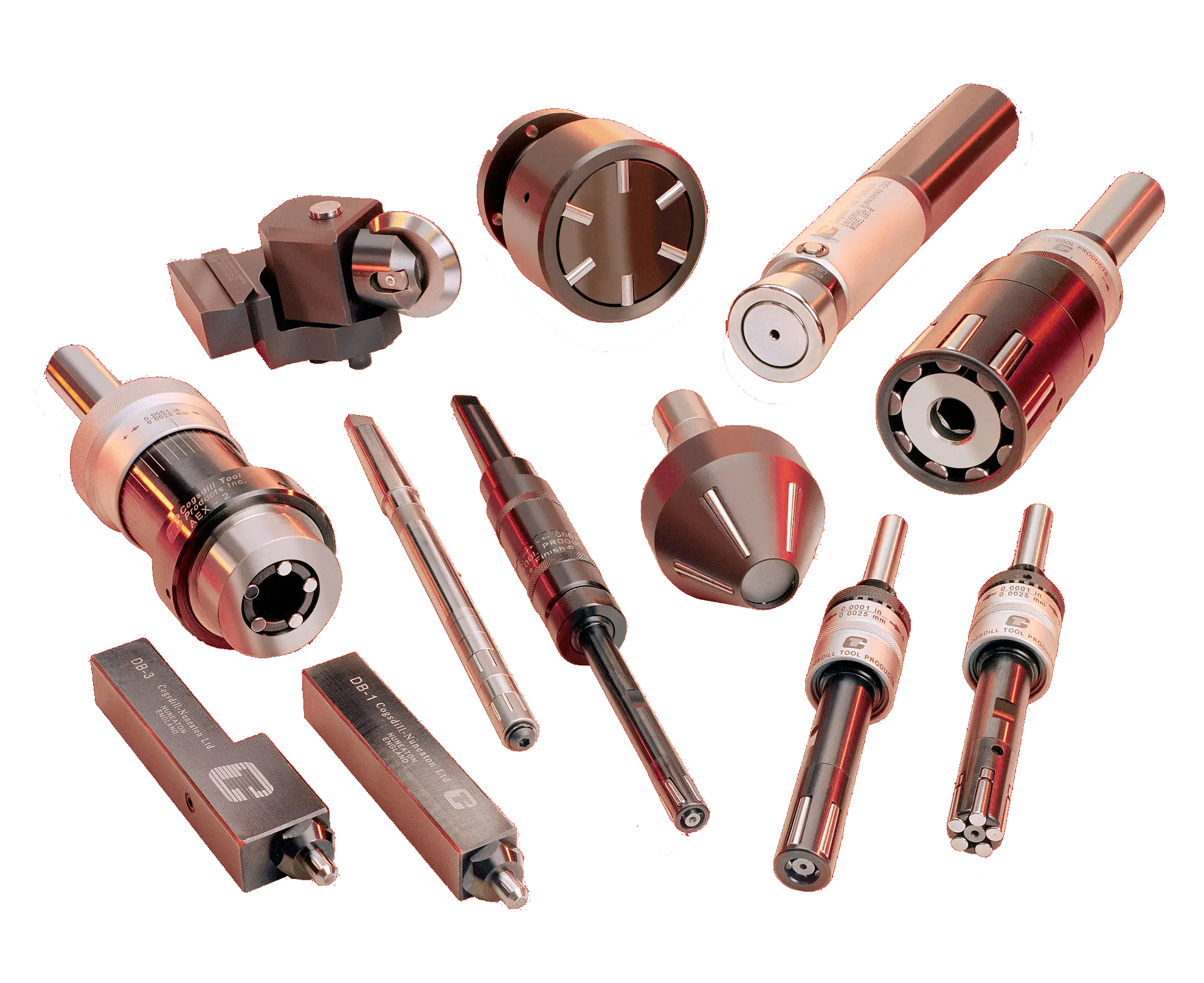

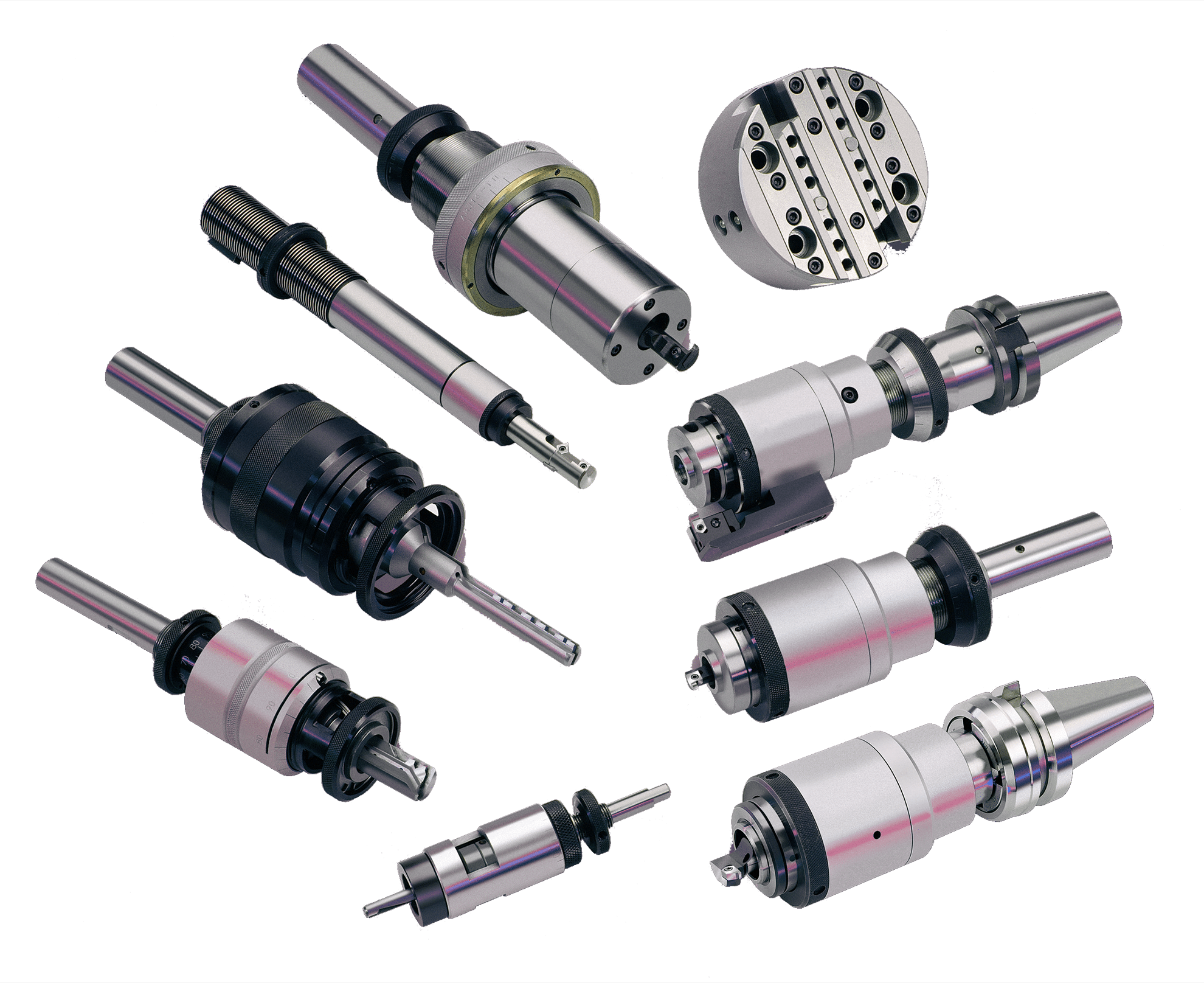

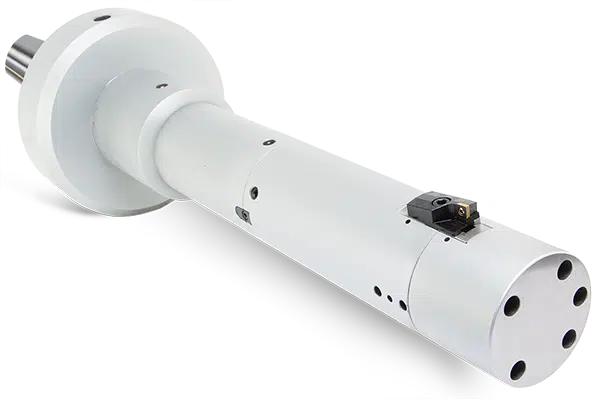

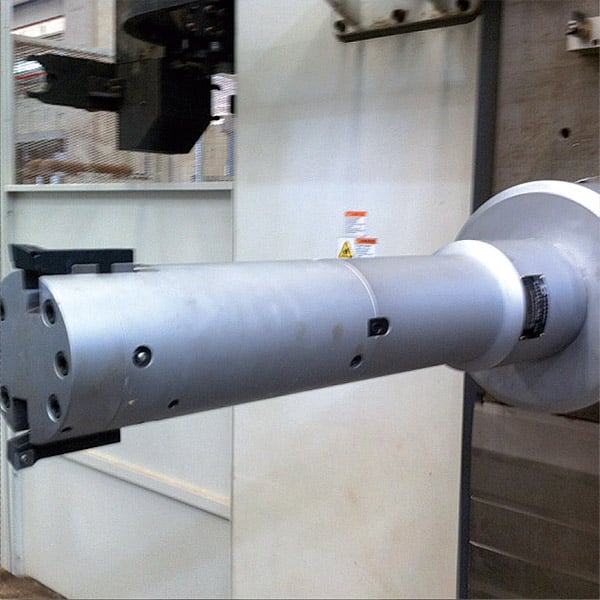

ZX Modular Boring Tools (MBT) offer versatility and economy when machining bores, counter-bores, tapers, threads, and complex contours inside components, over a wide range of diameters. These tools offer the highest cutting speeds and material removal rates available.

The MBT series is available in single-slide (MBT-S) and twin-slide (MBT-T) versions. All MBT tools feature 2:1 actuation ratio for easy programming.

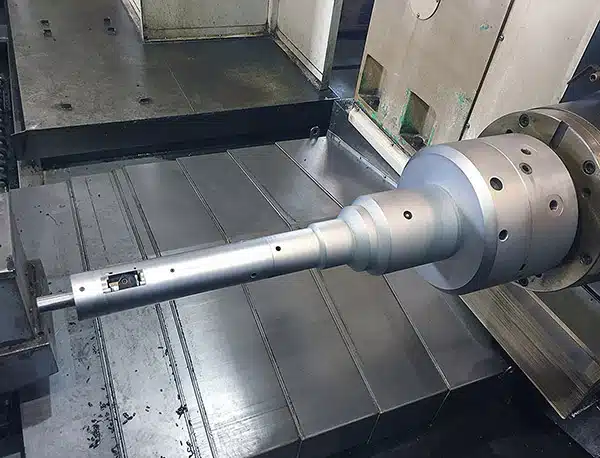

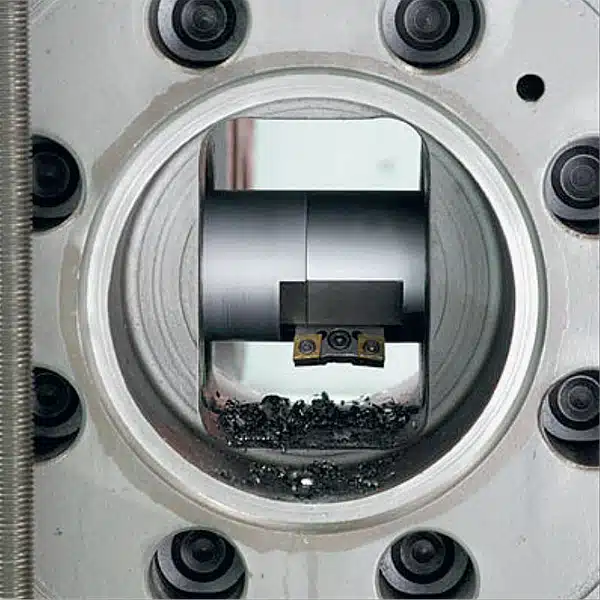

The unique modular design makes adjustment of length and configuration not only fast and easy, but cost effective too. The MBT range can simply be converted for valve seat pocket machining, bottle boring or other extended-reach applications with the addition of extensions and pilot supports – adding to their versatility and adaptability, whilst eliminating the need for additional tools. With a long tool slide stroke, that is supplemented by using different cartridges, they can cover an even wider diameter range – no need to change the tool slide(s) or remove the head from the machine. The tools can perform versatile forward and back boring operations, such as back counter-bores, internal grooves, faces, and bottle bores. Stepped and tapered bores are machined without tool changes offering exceptional concentricity. Accuracy is maintained as the tool slide(s) adjusts for various diameters whilst the tool stays on the same bore centerline.

Product features:

- Bottom-facing capability available for blind bores.

- Twin-slide tools offer balanced cutting forces for high feeds and speeds and high material removal rates.

- Internal through-tool coolant is standard.

- Fully enclosed actuation mechanism: No chip packing.

- Internal forward hard stop and anti-torque features protect the tool in case of mishaps.

Modular Design. Increased Functionality.

From short bores to long components with one extendable modular system.

We hold standard Modular Boring Tools in stock – other sizes available upon request.

MBT 50

MBT-50-S Modular Boring Tool (single slide)

| MBT-50-S | Through end cap | Bottoming end cap | |

| Tool Diameter | ⌀ 50 mm | ⌀ 50 mm | |

| Maximum Stroke | 23 mm | 18 mm | |

| Standard Capacity (default configuration) |

⌀ 50–96 mm | ⌀ 68–104 mm | |

| Maximum Capacity (extended cartridge/slide) |

⌀ 72–118 mm | ⌀ 76–112 mm | |

| Work Length | L1 ⌀ A | 315 mm : ⌀ 50 mm | 340 mm : ⌀ 68 mm |

| L4 ⌀ D | 531 mm : ⌀ 155 mm | 557 mm : ⌀ 155 mm | |

MBT 75

MBT-75-S Modular Boring Tool (single slide)

| MBT-75-S | Through end cap | Bottoming end cap | |

| Tool Diameter | ⌀ 75 mm | ⌀ 75 mm | |

| Maximum Stroke | 32 mm | 22 mm | |

| Standard Capacity (default configuration) |

⌀ 75–139 mm | ⌀ 75–119 mm | |

| Maximum Capacity (extended cartridge/slide) |

⌀ 150–214 mm | ⌀ 150–194 mm | |

| Work Length | L1 ⌀ A | 350 mm : ⌀ 75 mm | 386 mm : ⌀ 75 mm |

| L2 ⌀ B | 414 mm : ⌀ 86 mm | 450 mm : ⌀ 86 mm | |

| L3 ⌀ C | 454 mm : ⌀ 125 mm | 490 mm : ⌀ 125 mm | |

| L4 ⌀ D | 622 mm : ⌀ 155 mm | 658 mm : ⌀ 155 mm | |

MBT 100

MBT-100-S Modular Boring Tool (single slide)

| MBT-100-S | Through end cap | Bottoming end cap | |

| Tool Diameter | ⌀ 100 mm | ⌀ 75 mm | |

| Maximum Stroke | 45 mm | 23 mm | |

| Standard Capacity (default configuration) |

⌀ 100–190 mm | ⌀ 100–146 mm | |

| Maximum Capacity (extended cartridge/slide) |

⌀ 184–274 mm | ⌀ 184–230 mm | |

| Work Length | L1 ⌀ A | 454 mm : ⌀ 100 mm | 483 mm : ⌀ 100 mm |

| L2 ⌀ B | 486 mm : ⌀ 125 mm | 515 mm : ⌀ 125 mm | |

| L4 ⌀ D | 654 mm : ⌀ 155 mm | 684 mm : ⌀ 155 mm | |

MBT 125

MBT-125-S Modular Boring Tool (single slide)

| MBT-125-S | Through end cap | Bottoming end cap | |

| Tool Diameter | ⌀ 125 mm | ⌀ 125 mm | |

| Maximum Stroke | 54 mm | 30 mm | |

| Standard Capacity (default configuration) |

⌀ 125–233 mm | ⌀ 125–185 mm | |

| Maximum Capacity (extended cartridge/slide) |

⌀ 212–320 mm | ⌀ 212–272 mm | |

| Work Length | L1 ⌀ A | 524 mm : ⌀ 125 mm | 556 mm : ⌀ 125 mm |

| L4 ⌀ D | 692 mm : ⌀ 155 mm | 725 mm : ⌀ 155 mm | |

MBT Comparison Table

| TECHNICAL DATA | UNITS | MBT50 | MBT75 | MBT100 | MBT125 | ||||

| ⌀ A : Nominal Tool Diameter | mm | 49.8 | 73.0 | 100.0 | 123.8 | ||||

| ⌀ B : Tool Diameter (first stage) | mm | – | 86 | – | – | ||||

| ⌀ C : Tool Diameter (second stage) | mm | – | 125 | 125 | – | ||||

| ⌀ D : Tool Diameter (third stage) | mm | 155 | 155 | 155 | 155 | ||||

| RS : Max. Radial Stroke (through / bottoming) | mm | 23 | 18 | 32 | 22 | 45 | 23 | 54 | 30 |

| ⌀ X : Min. Standard Capacity (through / bottoming) | mm | 50 | 68 | 75 | 75 | 100 | 100 | 125 | 125 |

| ⌀ Y (through) / ⌀ Z (bottom) : Max. Extended Range * | mm | 118 * | 112 * | 214 * | 194 * | 274 * | 230 * | 320 * | 272 * |

| CL : Cartridge Length | mm | 35.0 | 44.4 | 50.8 | 63.5 | ||||

| L1 (through) / L5 (bottom) : Max. Working Length ⌀ A | mm | 315 | 340 | 350 | 386 | 454 | 483 | 524 | 556 |

| L2 (through) / L6 (bottom) : Max. Working Length ⌀ B | mm | – | – | 414 | 450 | 486 | 515 | – | – |

| L3 (through) / L7 (bottom) : Max. Working Length ⌀ C | mm | – | – | 454 | 490 | – | – | – | – |

| L4 (through) / L8 (bottom) : Max. Working Length ⌀ D | mm | 521 | 527 | 622 | 658 | 622 | 684 | 692 | 725 |

| AL : Adapter Length 4-pin (standard) / 2-pin (option) | mm | 95.3 | 104.3 | 95.3 | 104.3 | 95.3 | 104.3 | 95.3 | 104.3 |

| Maximum Speed | RPM | 800 | 800 | 800 | 800 | ||||

| Stoke Ratio | 2 to 1 | 2 to 1 | 2 to 1 | 2 to 1 | |||||

| Repeatibility Accuracy | mm | 0.003 | 0.003 | 0.003 | 0.003 | ||||

| Backlash | mm | +/- 0.025 | +/- 0.025 | +/- 0.025 | +/- 0.025 | ||||

| Boring Accuracy | H7 | H7 | H7 | H7 | |||||

| Max. chip removal on 080M46 steel | |||||||||

| Facing | D.O.C./mm | 3 | 3 | 3 | 3 | ||||

| Boring | D.O.C./mm | 3 | 6 | 7 | 7 | ||||

| Rapid Traverse | M/min | 100 | 100 | 100 | 100 | ||||

| Roughness | Ra | 0.8 | 0.8 | 0.8 | 0.8 | ||||

Special MBT Tools are also available in larger and smaller diameter sizes or equipped with special tool slides operating in bi-directional ways (for roughing and finishing without need to change the cartridge).

* Maximum Range requires Slide and Cartridge changes (see Insert charts).

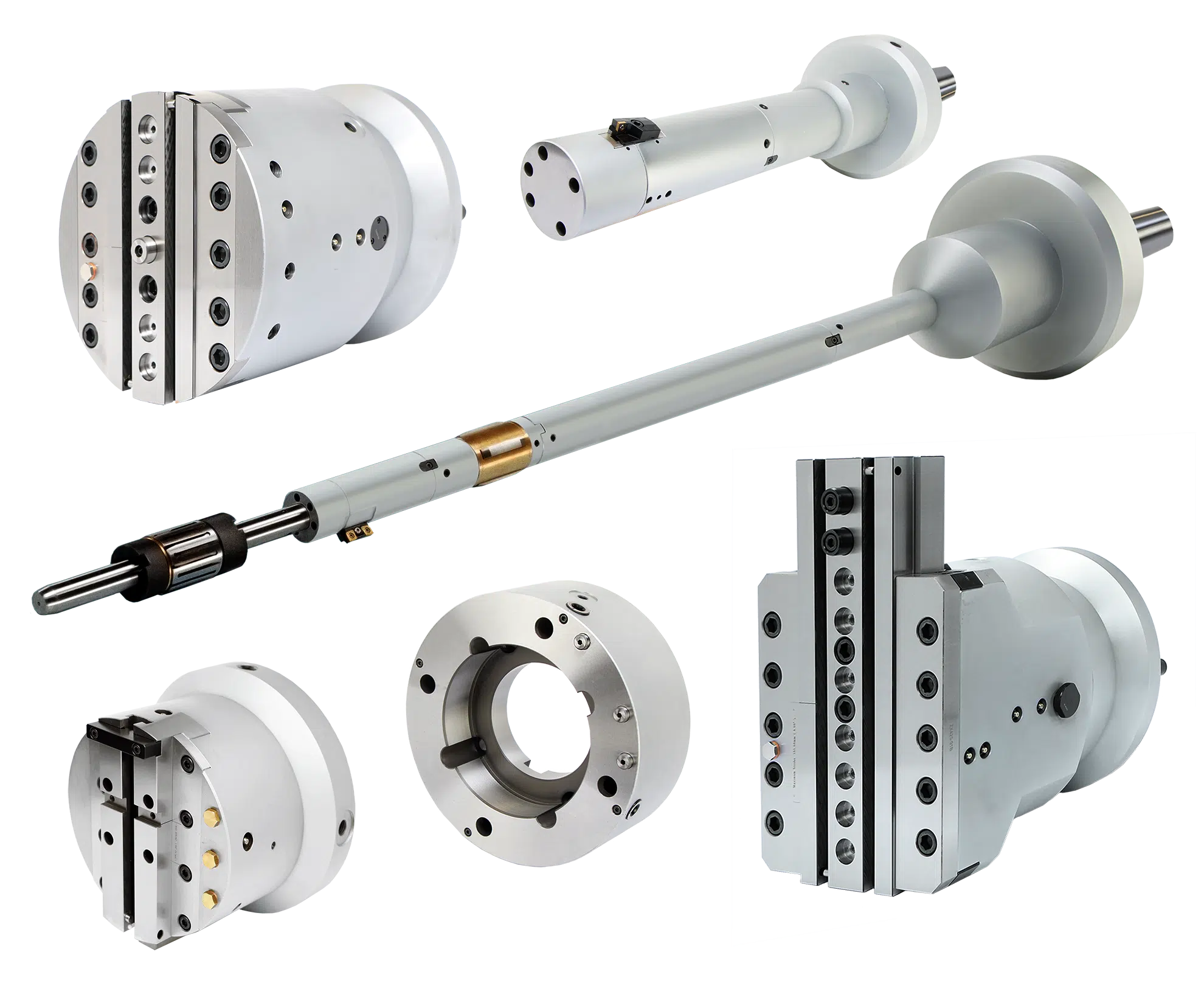

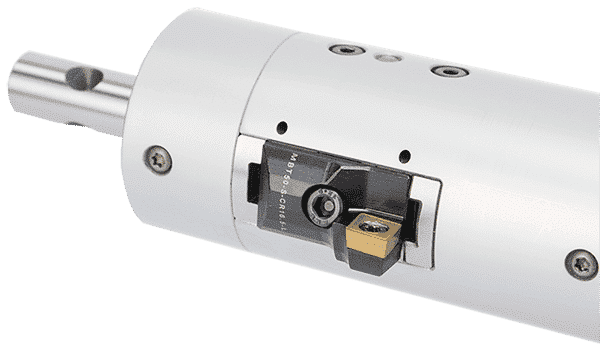

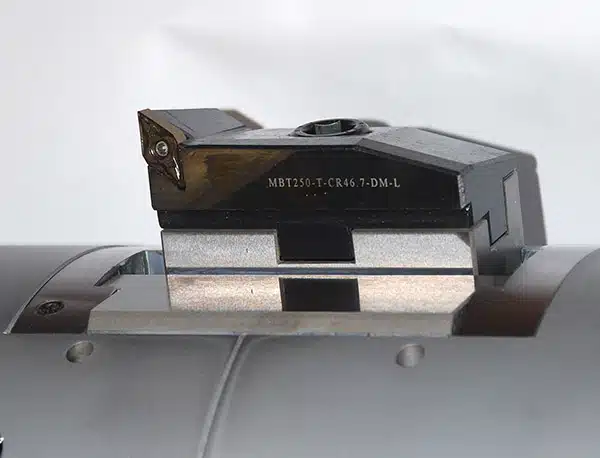

Insert Cartridges and Toolslides

Broad size range: Each tool has a long tool slide stroke that is supplemented by using different cartridges and toolslides to cover an ever wider diameter range. No need to change the toolslide(s) or remove the head from the machine.

Other special cartridge designs available on request: e.g. Burnishing Slide.

Twin pocket insert cartridge

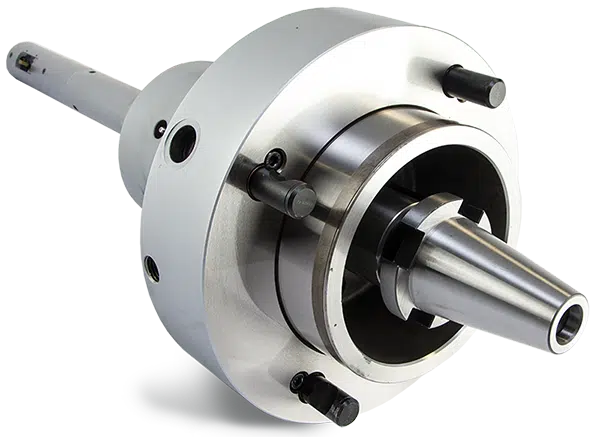

Twin slide MBT

Roller burnishing cartridge

MBT pick up station

Inserts Comparison Table

| TECHNICAL DATA | MBT50 | MBT75 | MBT100 | MBT125 | ||||

| CL : Cartridge Length | 35.0 | 44.4 | 50.8 | 63.5 | ||||

| RS : Max. Radial Stroke (through end) |

23 | 32 | 45 | 54 | ||||

| RS : Max. Radial Stroke (bottoming end) |

18 | 22 | 23 | 30 | ||||

Through End Maximum Range (⌀ X–⌀ Y) |

||||||||

| SR : TOOLSLIDE SLIDE RADIUS |

CR : CARTRIDGE CUT RADIUS | |||||||

| 16.5 mm | 21 mm | 23 mm | 35.5 mm | 23 mm | 35.5 mm | 27 mm | 44 mm | |

| 8.5 mm | 50–96 mm | 59–105 mm | ||||||

| 15.0 mm | 63–109 mm | 72–118 mm | ||||||

| 14.5 mm | 75–139 mm | 100–164 mm | ||||||

| 27.0 mm | 100–164 mm | 125–189 mm | 100–190 mm | 125–215 mm | ||||

| 39.5 mm | 125–189 mm | 150–214 mm | 125–215 mm | 150–240 mm | ||||

| 56.5 mm | 159–249 mm | 184–274 mm | ||||||

| 35.5 mm | 125–233 mm | 159–267 mm | ||||||

| 52.5 mm | 159–267 mm | 193–301 mm | ||||||

| 62.0 mm | 178–286 mm | 212–320 mm | ||||||

Bottoming End Maximum Range (⌀ X–⌀ Z) |

||||||||

| SR : TOOLSLIDE SLIDE RADIUS |

CR : CARTRIDGE CUT RADIUS | |||||||

| 16.5 mm | 21 mm | 23 mm | 35.5 mm | 23 mm | 35.5 mm | 27 mm | 44 mm | |

| 15.0 mm | 68–104 mm | 76–112 mm | ||||||

| 14.5 mm | 75–119 mm | 100–144 mm | ||||||

| 27.0 mm | 100–164 mm | 125–189 mm | 100–146 mm | 125–171 mm | ||||

| 39.5 mm | 125–189 mm | 150–214 mm | 125–171 mm | 150–196 mm | ||||

| 56.5 mm | 159–205 mm | 184–230 mm | ||||||

| 35.5 mm | 125–185 mm | 159–219 mm | ||||||

| 52.5 mm | 159–219 mm | 193–253 mm | ||||||

| 62.0 mm | 178–238 mm | 212–272 mm | ||||||

Other special cartridge designs available on request: e.g. Burnishing Slide.