Elliptical Illusion

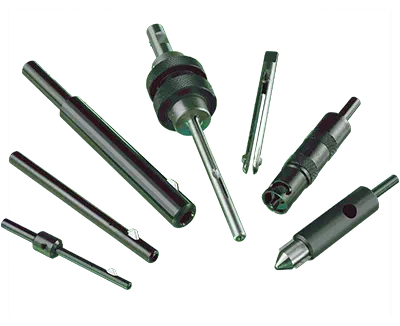

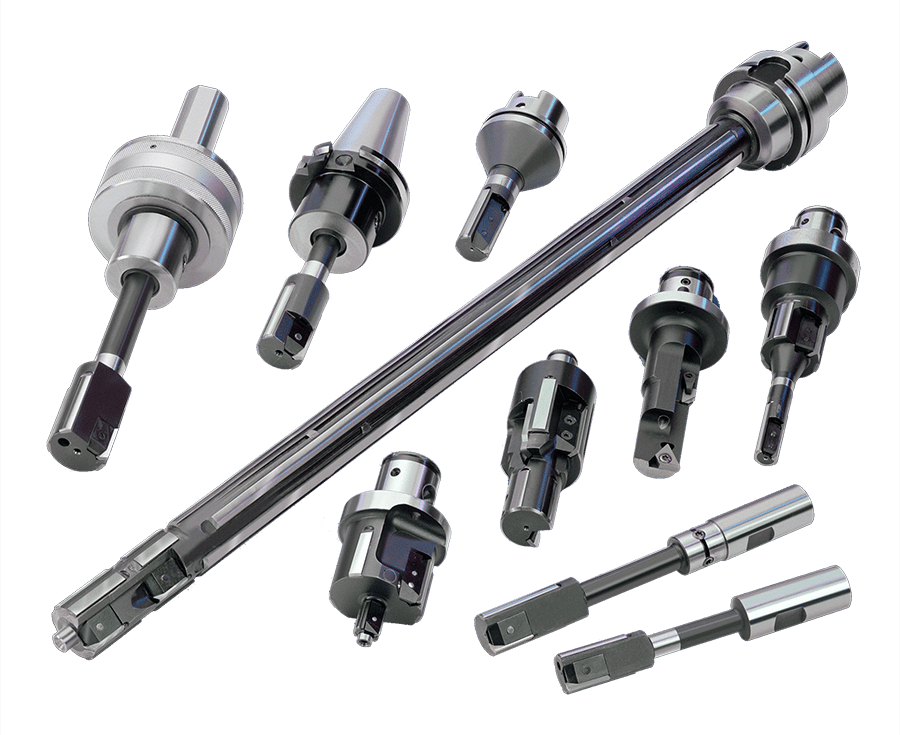

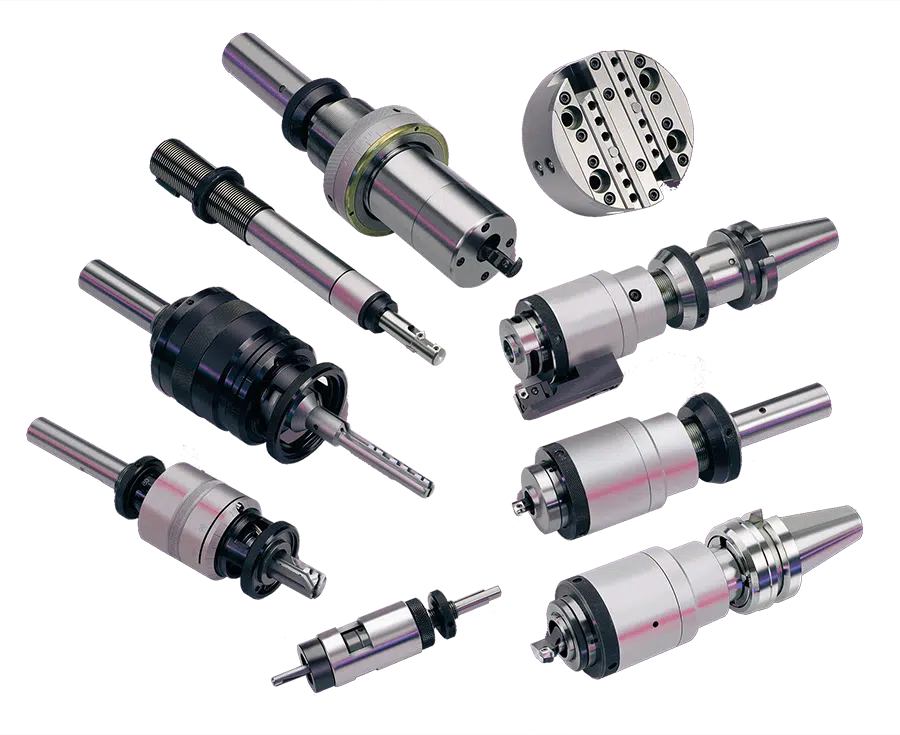

Deburring cylindrical, elliptical or other curved surfaces, used to challenge the most experienced engineers. Yet with the Ellipti-Bur, it’s now effortless simplicity.

The Ellipti-Bur® is designed for deburring irregular hole surfaces, such as those which are generated by drilling into curved surfaces, or by drilling at an angle. The Ellipti-Bur enables the user to perform these difficult deburring operations quickly and accurately, and without jigs, fixtures, or special operator skills.

The blade remains free to react to the irregular surface geometry of the hole, allowing for both radial and axial displacement resulting from the elliptical shape of angular drilled holes, and axial displacement (“rise and fall”) from the saddle shaped configuration of holes drilled in cylindrical surfaces.

This automatic self guiding feature produces a relatively uniform break on the edge of the hole.

How Ellipti-Bur tools work:

| 1 | As the pilot of the tool is located in the hole, the tool is seated and centered. |

| 2 | As the tool is advanced, the pilot is forced into the tool body against the shank spring, and the blade comes into contact with the edge of the hole – resulting in an oscillation motion both radially and axillary from the saddle-shape of the component. |

| 3 | As the tool continues to advance, the pilot is further pressed into the body and the blade is driven into the workpiece. |

Design Features

The Ellipti-Bur features a spring-loaded and self-centering conical pilot to locate and seat the tool for consistent results. All essential tool parts are hardened and ground for durability.

Three models cover a range of hole sizes from 5/32 to one inch (3.96 to 25.4mm).

The blade, which has two diametrically opposed cutting edges, is made from hardened high-speed steel and finish ground. A supplemental surface treatment provides for increased wear resistance.

Curved surfaces. Simply deburred.

A simple solution for burr removal on curved and elliptical components.

We hold a range of tool sizes and assortment of blades in stock.

Available for immediate shipping!

Standard Tool Specifications

| Tool No. | Operating Range | “C” Length | “D” Body | “E” Shank | “F” Degree | ||||||

| “A” (min) | “B” (max) | ||||||||||

| in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | ||

| EL-5 | 0.156 | 3.96 | 0.312 | 7.93 | 3.125 | 79.37 | 0.625 | 15.87 | 0.250 | 6.35 | 120˚ |

| EL-5XT* | 0.156 | 3.96 | 0.312 | 7.93 | 3.125 | 79.37 | 0.625 | 15.87 | 0.250 | 6.35 | 120˚ |

| EL-8 | 0.250 | 6.35 | 0.500 | 12.70 | 3.250 | 82.55 | 0.750 | 19.05 | 0.250 | 6.35 | 120˚ |

| EL-16 | 0.375 | 9.52 | 1.000 | 25.40 | 4.750 | 120.65 | 1.000 | 25.40 | 0.500 | 12.70 | 120˚ |

*Blades for the EL-5XT are made from a premium grade high speed steel and recommended for applications where longer tool life is desired, such as when coolant is unavailable.

Note: Operating range is determined by pilot diameter, not by cutter width.