Shefcut ® Reaming

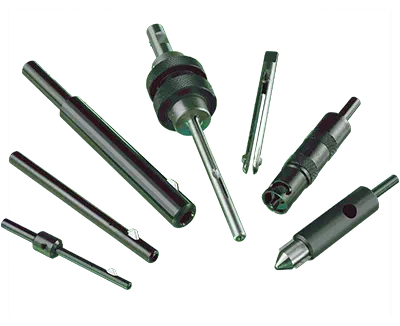

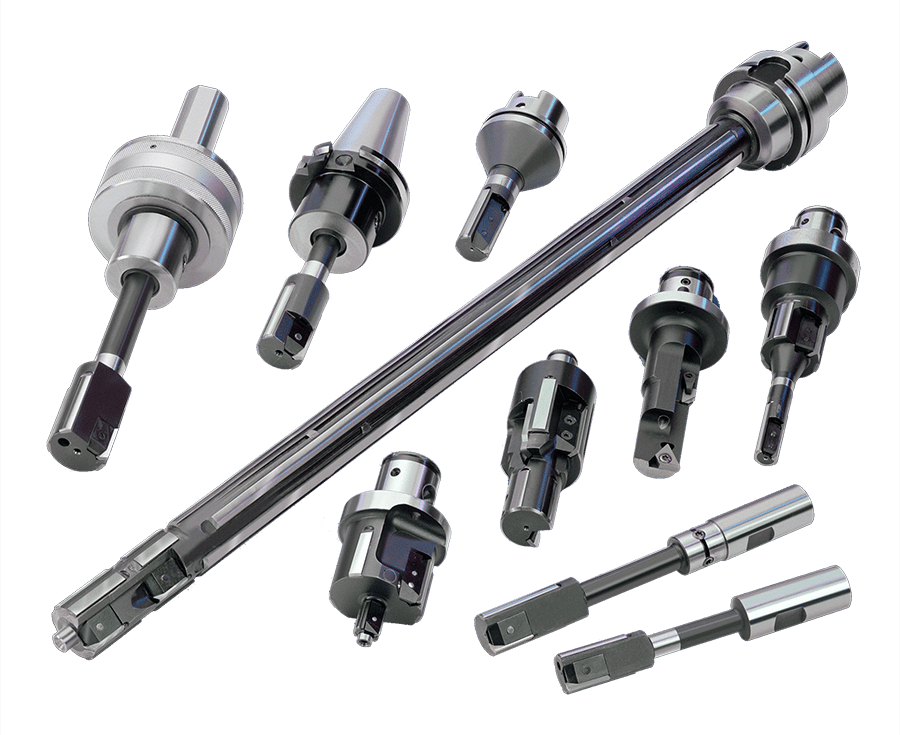

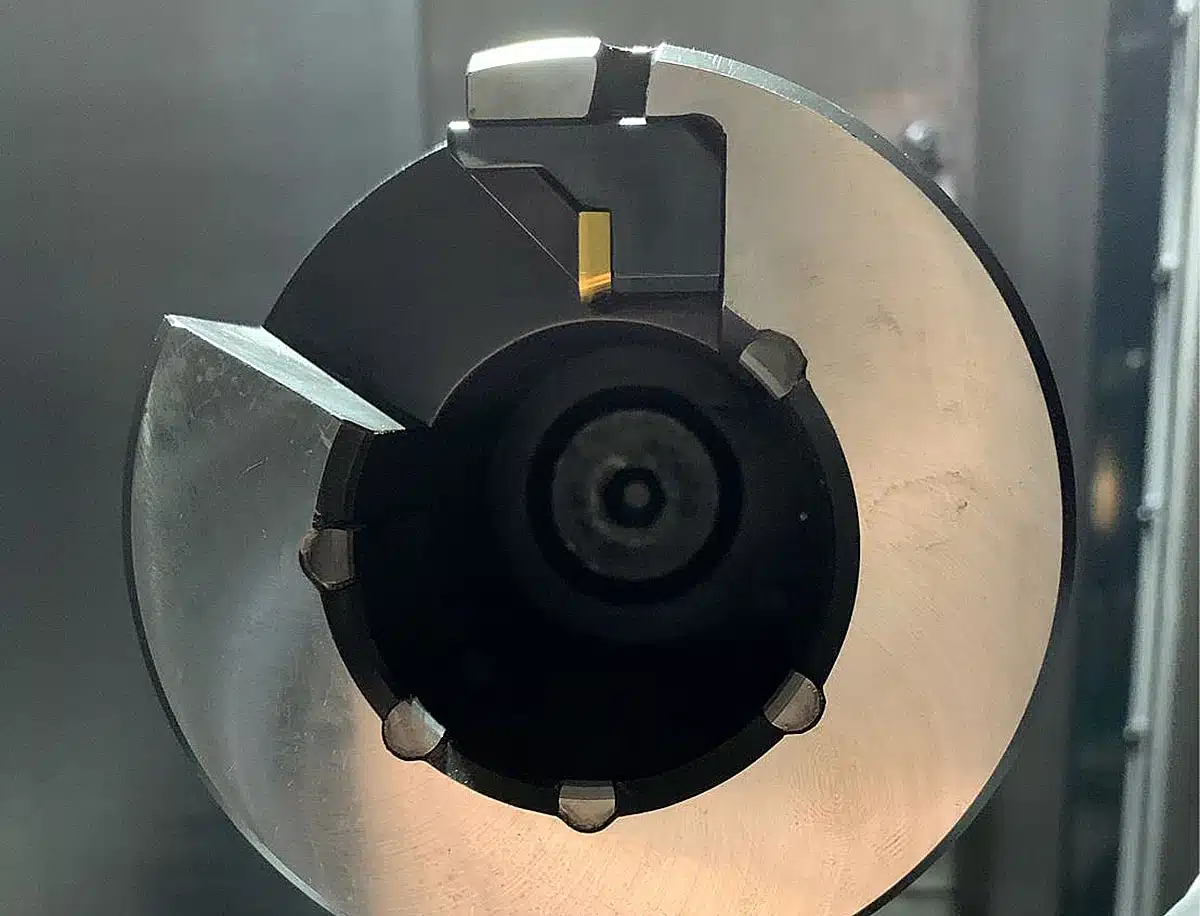

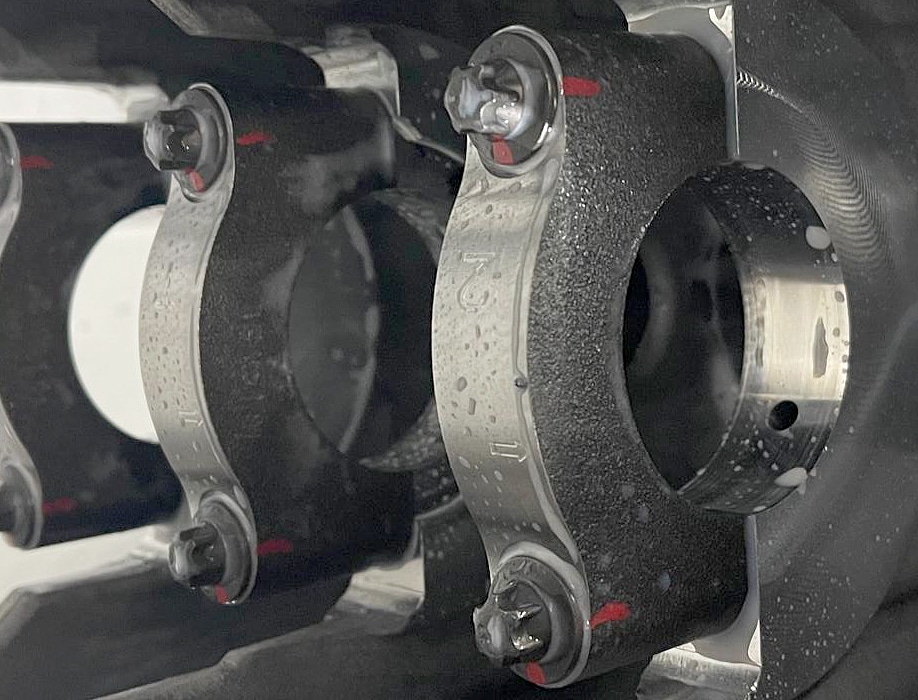

Shefcut precision reamers and boring tools are designed to produce accurately sized, extremely straight and round bores with fine surface finishes. Multiple guide pads rigidly support a single, replaceable cutting blade for exceptional stability and alignment. Size control, surface finish quality, and hole geometry are superior, compared to results from conventional reamers and boring tools.

Each tool is designed for a specific cut diameter. Standard and custom tool designs are offered. Also available from Cogsdill: tool holders designed to complement and enhance the performance of Shefcut tools, and Shefcut setting fixtures for fast and accurate tool settings.

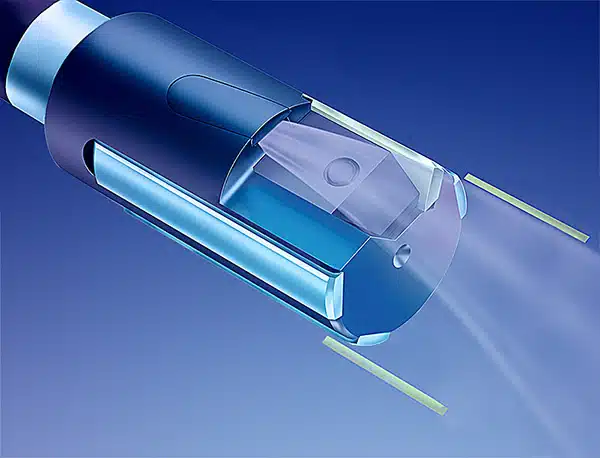

The Shefcut design concept

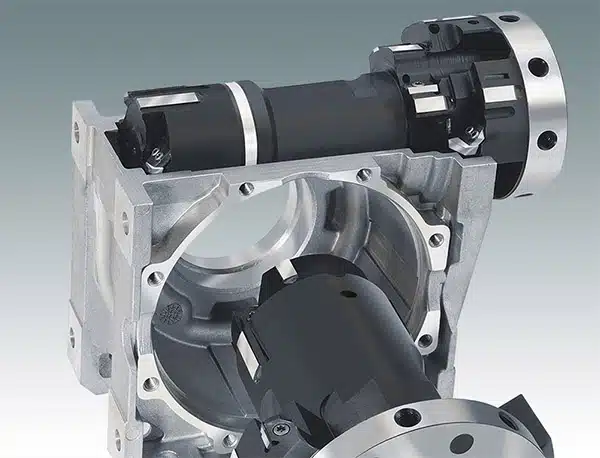

Conventional multi-fluted reamers are guided by their cutting edges. The Shefcut design separates the cutting, guiding, and supporting functions of the tool for maximum advantage.

Because the cutting blade is independent of the tool body, it can be micro-adjusted over a limited range and pre-set to a cut diameter that the tool will then produce with consistent accuracy. Worn cutting blades can be replaced quickly and easily.

Pads that are independent of the cutting blade optimize the guiding and supporting functions of the tool. While the tool is in operation, cutting forces are opposed by pad reaction forces in perfect balance, providing rigid support for the blade edge. Pads can be tailored to suit the application; e.g., for interrupted cuts, piloted operations, etc.

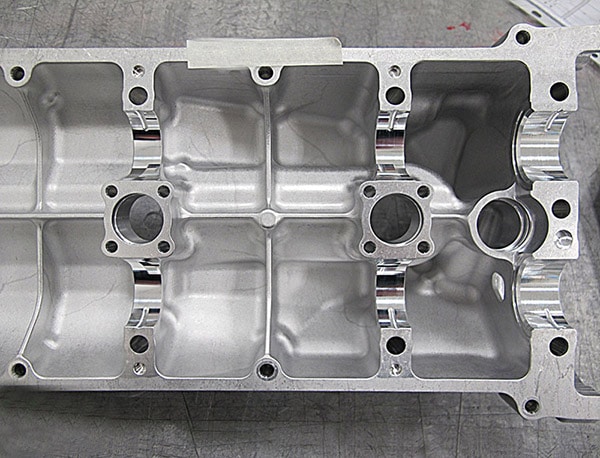

Fine surface finishes

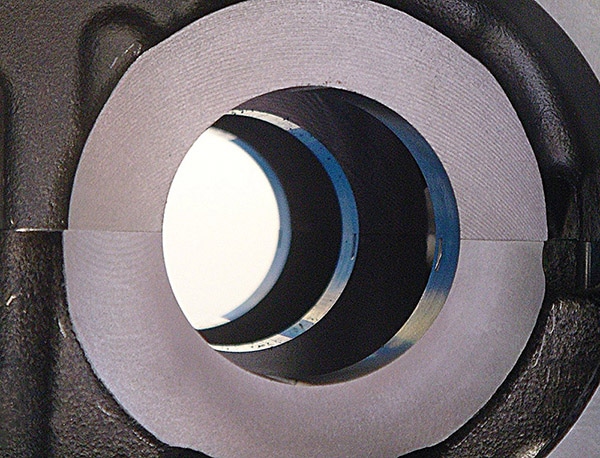

Shefcut produces lower surface finishes than conventional cutting tools. Surface finishes as fine as 0.1 micrometers (4 microinches) Ra or better are attainable in some materials.

The face of the Shefcut blade is highly polished to reduce friction between chip and blade, which in turn reduces the tendency toward edge build-up. The Shefcut blade has a very sharp edge, and the cutting geometry reduces chip thickness. These blade design advantages, along with the rigid support provided to the blade by the guide pads, enable the user to achieve excellent surface finishes.

Accurate sizing and superior bore geometry

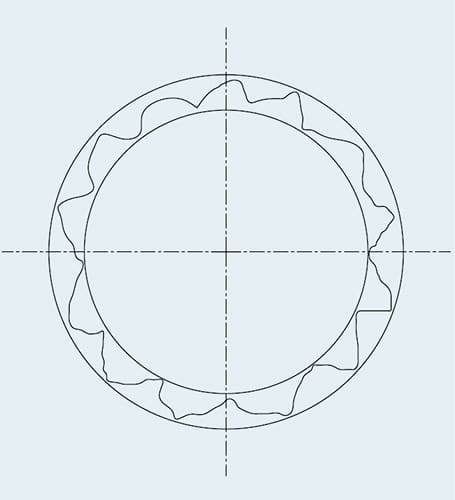

The Shefcut tool produces hole geometry that is superior to the hole geometry produced by conventional reamers. Since multifluted reamers are guided by the cutting edges, they inevitably generate a lobed bore geometry (refer to figure 1). The Shefcut design produces better hole geometry due to rigid support of the cutting blade by the guide pads (see figure 2).

Bore tolerances, including straightness and roundness, can usually be held within 5 microns (.0002 inch) using Shefcut tools on typical shop equipment, provided that reasonable care is taken.

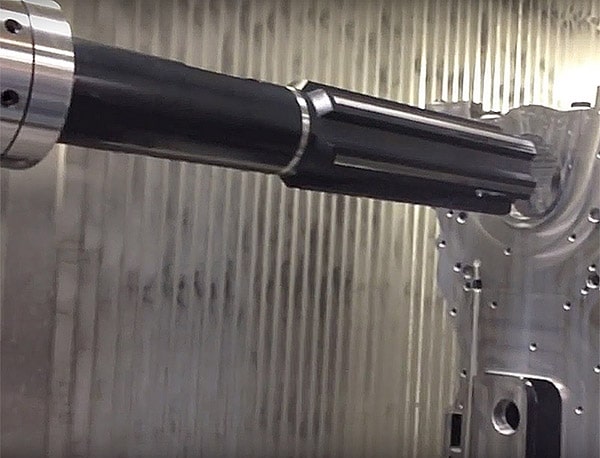

Accurate and consistent performance

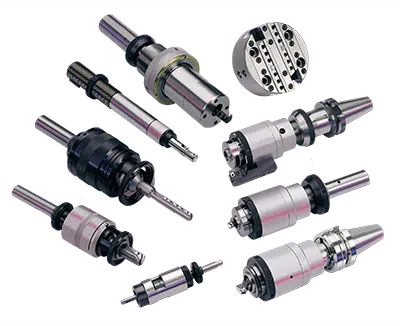

Advances in machine tool spindle speeds and accuracy, along with improved tool materials (such as PCD) and more accurate tool-to-spindle connections, have revolutionized manufacturing processes. Today’s higher performance machine tools demand higher performance tooling. Shefcut ensures maximum efficiency from high-speed, highly accurate machines. The tools can be pre-set to achieve the required size and finish with minimal part-to-part variation.

Fine Surface Finish. No Deflection.

Accurate sizing and superior bore geometry with consistent performance.

Shefcut World Reamer

The Shefcut World Reamer program includes tools of a standard design suited for precision reaming applications.

The World Reamer features a rigid blade-clamping system offering the greatest possible amount of chip clearance for maximum tool performance.

The tools are available for popular hole sizes, both metric and inch. They are offered in two lengths, with through-hole or blind-bore internal coolant, or external flood coolant. Tools with cermet pads are available on request for ferrous material applications.

World Reamers are available on a quick delivery basis. Blanks are stocked and tools are built to order to suit a specific cut diameter.

The Shefcut design concept can be adapted to a wide variety of standard and special tool configurations to suit your application.

Operating Requirements

Internal coolant options for Shefcut Tools.

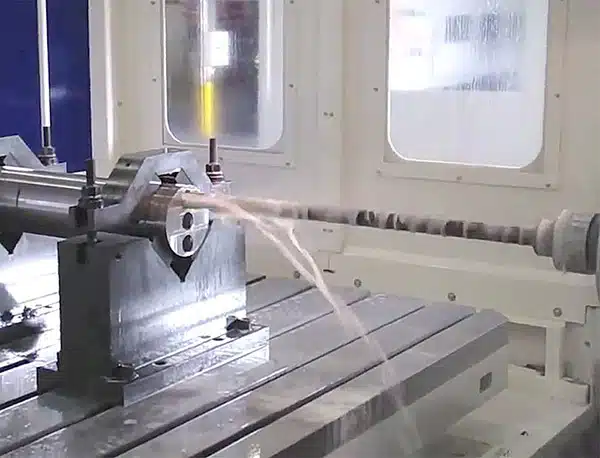

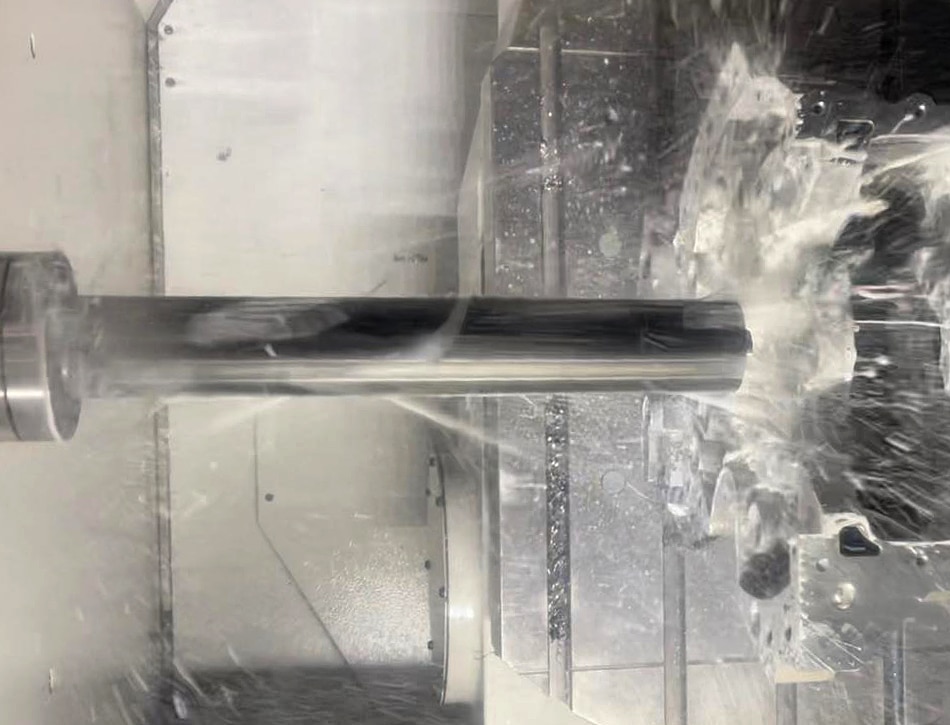

Coolant usage and selection is a critically important factor in maximizing Shefcut tool performance. As a general rule, Shefcut tools should not be run dry. A flood of clean coolant should be directed along the blade for lubrication and clearing of chips (swarf). (NOTE: Special Shefcut dry-cutting tools, and tools for spray-mist applications, are designed and built to order. Contact Cogsdill to discuss your application.)

We strongly recommend using a coolant with good lubricity, especially when machining nonferrous materials. Refer to the Coolant Selection and Coolant Flow Rate charts on this page for guidance in selecting the appropriate coolant for your material type. Internal coolant is available for both through-bore and blind-bore applications.

Internal coolant is recommended where the following conditions exist:

- When machining blind bores where the depth of the bore is more than twice the diameter.

- Where guide bushings or fixtures are used, or in applications where chip clearance problems are likely to occur.

- When machining at high cutting speeds.

- When machining long through-bores.

Through-Hole

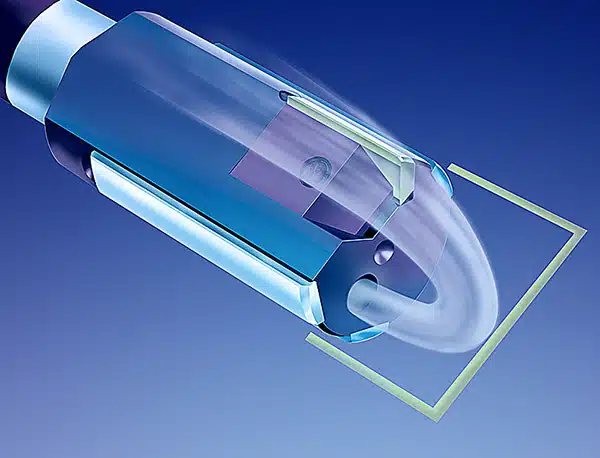

For through-hole tools with internal coolant, the coolant flows through the center of the tool and exits above the blade and pads, flushing chips out of the bore ahead of the tool.

Blind-Bore

For blind-bore tools with internal coolant, the coolant exits at the end of the cutting head, flushing the chips back and out of the entrance of the blind bore.

| COOLANT SELECTION | |

| MATERIAL TYPE | COOLANT RECOMMENDATION |

| Steel | Soluble 12% |

| Nickel chrome steel | Soluble 12% |

| Stainless steel | Soluble 12-14% |

| Cast iron | Soluble/Synthetic |

| Aluminium | Soluble 12-14% |

| Zinc alloys | Soluble 12% |

| Copper | Soluble 10-12% |

| Brass | Soluble 10-12% |

| INTERNAL COOLANT FLOW RATE | |||||

| REAMER DIAMETER | PRESSURE | VOLUME | |||

| mm | in. | bar | psi | liters/min | gal/min |

| 6-20 | .236-.787 | 6-20 | 87-290 | 6-20 | 1.5-5.3 |

| >20 | >.787 | 3-10 | 44-125 | 20-100 | 5.3-26.4 |

Machining allowance

The bore size and finish prior to reaming must allow sufficient depth of cut for the reamer to remove all tool marks from the pre-machined hole. Refer to the catalogue for recommended machining allowances when using standard cutting leads.

NOTE: A maximum allowance of 0.15mm (.006 in.) on diameter is recommended when machining stainless steel.

Alignment

Shefcut reaming or boring requires accurate alignment of machine spindle to workpiece. Misalignment will reduce tool performance and bore quality, and may result in blade damage.

In Shefcut reaming applications, a floating holder may correct misalignment problems. Precision boring operations performed with a Shefcut tool may require the use of an adjustable holder (see “Tool Holders,” in catalogue).

Power feed

Power feed is essential for consistent cutting pressure on the Shefcut tool. Handfeeding the tool could result in poor tool performance and probable tool damage.

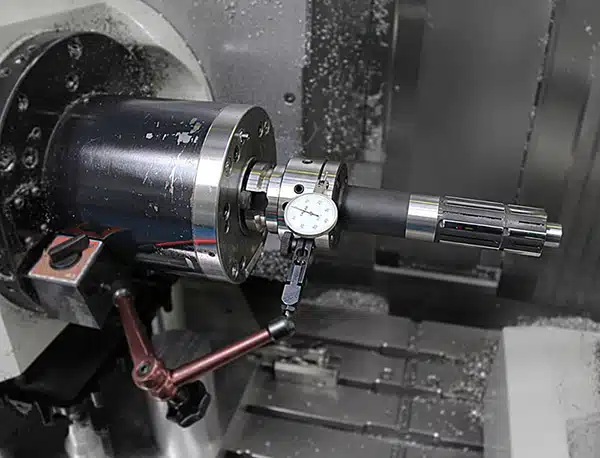

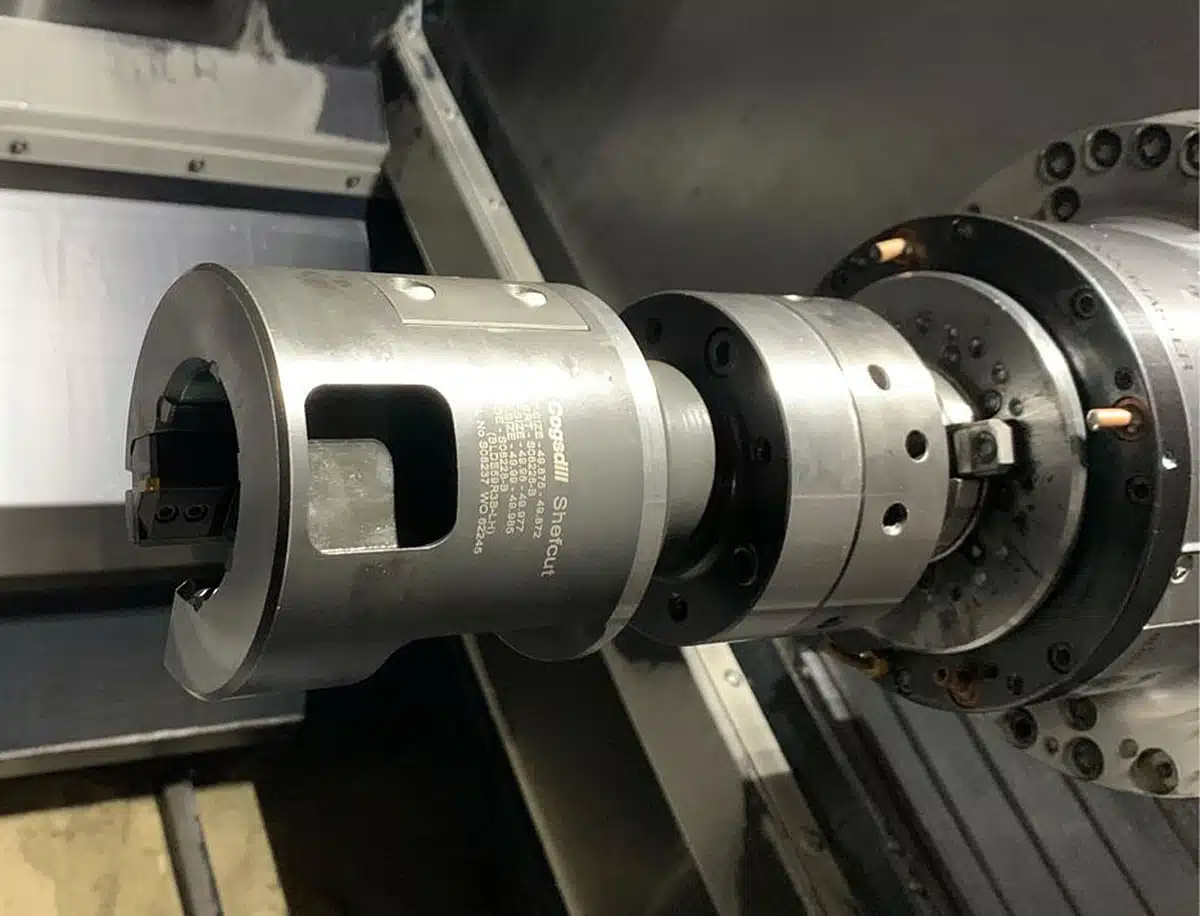

Lathe applications

Position the blade in the “up” position when using a Shefcut reamer on a lathe or in any application where the tool is held stationary in the horizontal position while the workpiece rotates. Use of a floating holder will correct any turret indexing errors.