Rapid fire

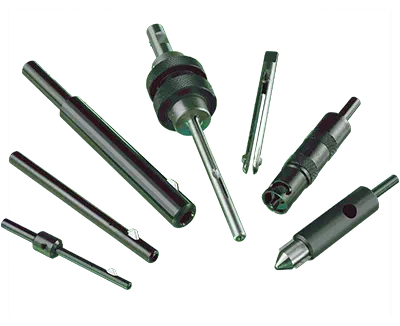

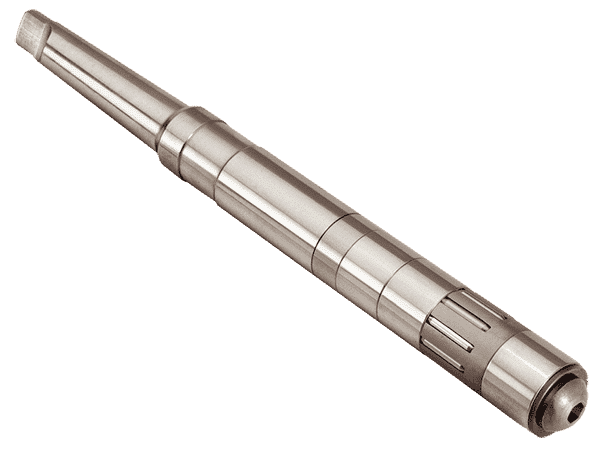

The Bearingizing Tool combines roller burnishing with peening action. As the tool is rotated at a high speed the rolls spin, rise, and fall over a cammed arbor, delivering up to 200,000 rapid fire blows per minute to the work surface. The peaks and valleys of the machined surface are compacted into a smooth, hardened, and ultra fine surface finish.

The Bearingizer may be the tool of choice when the following conditions exist:

- Parts with thin walls — Bearingizing eliminates barrel-shaping of the part.

- Parts with irregular wall thicknesses — the Bearingizing tool will produce a very round hole, whereas the Roll-a-Finish® tool might generate a slightly egg-shaped hole, due to variations in wall thickness.

- Applications where porosity is an issue (e.g., oil-impregnated bearings) — the smaller “footprint” of the Bearingizing roll leaves pores in the surface intact.

- Applications where very tight tolerances must be held — the Bearingizer reduces springback in the work surface material. The Bearingizing tool can, in some materials and with proper part preparation, hold size as close as ±.0001 inch (.002mm), while the Roll-a-Finish tool can achieve tolerances of ±.00025 inch (.006mm).

Where the above conditions do not exist, the Roll-a-Finish® tool would generally be the tool of choice, for two reasons:

- The relatively wide adjustment range of the Roll-a-Finish tool, which is typically .040 inch (1.01mm), and

- The ease of adjustment, with the castellated adjusting collar on the Roll-a-Finish tool.

The Bearingizing tool features a greater number of rolls, and rolls of a smaller diameter, as compared to the Roll-a-Finish tool, and can only be adjusted by change of rolls. The Bearingizer also requires a closer presize than the Roll-a-Finish tool.

Where the above conditions do exist, the Bearingizing tool should be considered. While the Roll-a-Finish Tool increases surface hardness by about 5 to 10%, Bearingizing increases hardness by 10 to 30%, but with less surface penetration.

Multiple Positions

Bearingizing tools provide three roll positions over the cammed arbor (see right). When the forward (#1 position) of cam becomes worn, the roll cage can be re-positioned to the # 2 and # 3 positions by exchanging positions with the movable collars. This presents NEW cam surfaces and original BUILD-UP. After all positions on the cam are worn beyond producing acceptable parts, oversize rolls can be used to further extend tool life. Roll sizes are available in increments of .0001 inch (.0025 mm) and the tool will accommodate a range of roll sizes up to .002 inch (.0508 mm).

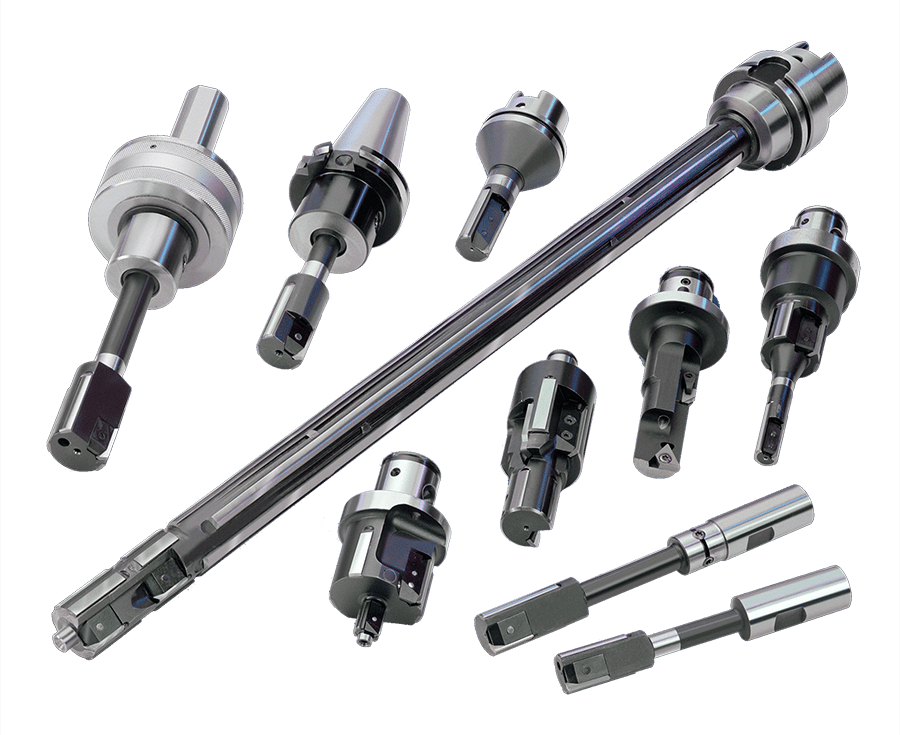

Can be used in three positions:

- Through-hole applications.

- Semi-bottoming applications.

- Bottoming applications.

Standard Tool Specifications

| NOMINAL | BUILD-UP RANGE | CAM | SHANK | OVERALL LENGTH | WORK LENGTH | NO. | ||||||||

| TOOL SIZE | DIAMETER | DIAMETER | MAXIMUM | MINIMUM | OF | |||||||||

| INCHES | MM | INCHES | MM | INCHES | MM | INCHES | MM | INCHES | MM | INCHES | MM | INCHES | MM | ROLLS |

| .188 | 4.76 | .1861 | 4.727 | .1281 | 3.254 | .500 | 12 | 5.5 | 139.7 | 2.938 | 74.61 | 2.188 | 55.56 | 6 |

| .1901 | 4.829 | |||||||||||||

| .219 | 5.56 | .2174 | 5.522 | .1594 | 4.049 | .500 | 12 | 5.5 | 139.7 | 2.938 | 74.61 | 2.188 | 55.56 | 6 |

| .2214 | 5.624 | |||||||||||||

| .236 | 6 | .2343 | 5.951 | .1670 | 4.242 | .500 | 12 | 6 | 152.4 | 3.438 | 87.31 | 2.375 | 60.32 | 6 |

| .2383 | 6.053 | |||||||||||||

| .250 | 6.35 | .2486 | 6.314 | .1806 | 4.587 | .500 | 12 | 6 | 152.4 | 3.438 | 87.31 | 2.375 | 60.32 | 6 |

| .2526 | 6.416 | |||||||||||||

| .276 | 7 | .2743 | 6.967 | .2064 | 5.243 | .500 | 12 | 6 | 152.4 | 3.438 | 87.31 | 2.313 | 58.74 | 6 |

| .2783 | 7.069 | |||||||||||||

| .281 | 7.14 | .2799 | 7.109 | .2119 | 5.382 | .500 | 12 | 6 | 152.4 | 3.438 | 87.31 | 2.313 | 58.74 | 6 |

| .2839 | 7.211 | |||||||||||||

| .313 | 7.94 | .3112 | 7.904 | .2212 | 5.618 | .500 | 12 | 6 | 152.4 | 3.438 | 87.31 | 2.313 | 58.74 | 6 |

| .3152 | 8.006 | |||||||||||||

| .315 | 8 | .3137 | 7.968 | .2238 | 5.667 | .500 | 12 | 6 | 152.4 | 3.438 | 87.31 | 2.313 | 58.74 | 6 |

| .3177 | 8.069 | |||||||||||||

| .343 | 8.73 | .3425 | 8.700 | .2525 | 6.414 | .500 | 12 | 7 | 177.8 | 4.438 | 112.71 | 3.063 | 77.79 | 6 |

| .3465 | 8.801 | |||||||||||||

| .354 | 9 | .3530 | 8.966 | .2631 | 6.683 | .500 | 12 | 7 | 177.8 | 4.438 | 112.71 | 3.063 | 77.79 | 6 |

| .3570 | 9.068 | |||||||||||||

| .375 | 9.53 | .3738 | 9.495 | .2518 | 6.396 | .500 | 12 | 7 | 177.8 | 4.438 | 112.71 | 3.125 | 79.38 | 6 |

| .3778 | 9.596 | |||||||||||||

| .394 | 10 | .3965 | 9.970 | .2705 | 6.871 | .500 | 12 | 7 | 177.8 | 4.438 | 112.71 | 3.125 | 79.38 | 6 |

| .3925 | 10.071 | |||||||||||||

| .406 | 10.32 | .4051 | 10.290 | .2831 | 7.191 | .500 | 12 | 8 | 203.2 | 5.438 | 138.11 | 3.563 | 90.49 | 6 |

| .4091 | 10.391 | |||||||||||||

| .433 | 11 | .4320 | 10.973 | .2779 | 7.059 | .500 | 12 | 8 | 203.2 | 5.438 | 138.11 | 3.688 | 93.66 | 6 |

| .4360 | 11.074 | |||||||||||||

| .438 | 11.11 | .4365 | 11.087 | .2825 | 7.176 | .500 | 12 | 8 | 203.2 | 5.438 | 138.11 | 3.688 | 93.66 | 6 |

| .4405 | 11.189 | |||||||||||||

| .469 | 11.91 | .4678 | 11.882 | .3138 | 7.971 | .500 | 12 | 8 | 203.2 | 5.438 | 138.11 | 3.688 | 93.66 | 8 |

| .4718 | 11.984 | |||||||||||||

| .472 | 12 | .4710 | 11.963 | .3174 | 8.062 | .500 | 12 | 8 | 203.2 | 5.438 | 138.11 | 3.688 | 93.66 | 8 |

| .4750 | 12.065 | |||||||||||||

| .500 | 12.70 | .4990 | 12.675 | .3450 | 8.763 | .500 | 12 | 8 | 203.2 | 5.438 | 138.11 | 3.688 | 93.66 | 8 |

| .5030 | 12.776 | |||||||||||||

| .512 | 13 | .5110 | 12.979 | .3568 | 9.063 | .500 | 12 | 8 | 203.2 | 5.438 | 138.11 | 3.688 | 93.66 | 8 |

| .5150 | 13.081 | |||||||||||||

| .531 | 13.49 | .5303 | 13.470 | .3763 | 9.558 | .500 | 12 | 8 | 203.2 | 5.438 | 138.11 | 3.688 | 93.66 | 8 |

| .5343 | 13.571 | |||||||||||||

| .551 | 14 | .5500 | 13.970 | .3962 | 10.063 | .500 | 12 | 8 | 203.2 | 5.438 | 138.11 | 3.688 | 93.66 | 8 |

| .5540 | 14.072 | |||||||||||||

| .563 | 14.29 | .5615 | 14.262 | .4075 | 10.351 | .500 | 12 | 8 | 203.2 | 5.438 | 138.11 | 3.688 | 93.66 | 8 |

| .5655 | 14.364 | |||||||||||||

| .591 | 15 | .5896 | 14.976 | .4356 | 11.064 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 8 |

| .5936 | 15.077 | |||||||||||||

| .594 | 15.09 | .5928 | 15.057 | .4388 | 11.146 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 8 |

| .5968 | 15.159 | |||||||||||||

| .625 | 15.87 | .6240 | 15.850 | .4390 | 15.151 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 8 |

| .6280 | 15.951 | |||||||||||||

| .630 | 16 | .6290 | 15.977 | .4439 | 11.275 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 8 |

| .6330 | 16.078 | |||||||||||||

| .656 | 16.67 | .6553 | 16.645 | .4703 | 11.946 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 8 |

| .6593 | 16.746 | |||||||||||||

| .669 | 17 | .6680 | 16.967 | .4833 | 12.276 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 8 |

| .6720 | 17.069 | |||||||||||||

| .688 | 17.46 | .6865 | 17.437 | .5015 | 12.738 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 8 |

| .6905 | 17.539 | |||||||||||||

| .709 | 18 | .7080 | 17.983 | .5227 | 13.277 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 10 |

| .7120 | 18.085 | |||||||||||||

| .719 | 18.26 | .7178 | 18.232 | .5328 | 13.533 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 10 |

| .7218 | 18.334 | |||||||||||||

| .748 | 19 | .7470 | 18.974 | .5620 | 14.275 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 10 |

| .7510 | 19.075 | |||||||||||||

| .750 | 19.05 | .7490 | 19.025 | .5640 | 14.326 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 10 |

| .7530 | 19.126 | |||||||||||||

| .781 | 19.84 | .7803 | 19.820 | .5953 | 15.121 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 10 |

| .7843 | 19.921 | |||||||||||||

| .787 | 20 | .7860 | 19.964 | .6014 | 15.276 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 10 |

| .7900 | 20.066 | |||||||||||||

| .813 | 20.64 | .8115 | 20.612 | .6265 | 15.913 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 10 |

| .8155 | 20.714 | |||||||||||||

| .827 | 21 | .8260 | 20.980 | .6408 | 16.276 | .750 | 20 | 8 | 203.2 | 4.875 | 123.83 | 3.125 | 79.38 | 10 |

| .8300 | 21.082 | |||||||||||||

| .844 | 21.43 | .8428 | 21.407 | .5958 | 15.133 | .750 | 20 | 9 | 228.60 | 5.875 | 149.23 | 3.75 | 95.25 | 10 |

| .8468 | 21.509 | |||||||||||||

| .866 | 22 | .8650 | 21.971 | .6181 | 15.700 | .750 | 20 | 9 | 228.60 | 5.875 | 149.23 | 3.75 | 95.25 | 10 |

| .8690 | 22.076 | |||||||||||||

| .875 | 22.22 | .8740 | 22.200 | .6270 | 15.926 | .750 | 20 | 9 | 228.60 | 5.875 | 149.23 | 3.75 | 95.25 | 10 |

| .8780 | 22.301 | |||||||||||||

| .905 | 23 | .9050 | 22.987 | .6583 | 16.721 | 1.000 | 25 | 10 | 254.00 | 6.125 | 155.58 | 4.00 | 101.60 | 10 |

| .9090 | 23.087 | |||||||||||||

| .906 | 23.02 | .9053 | 22.995 | .6583 | 16.721 | 1.000 | 25 | 10 | 254.00 | 6.125 | 155.58 | 4.00 | 101.60 | 10 |

| .9093 | 23.096 | |||||||||||||

| .938 | 23.81 | .9365 | 23.787 | .6895 | 17.513 | 1.000 | 25 | 10 | 254.00 | 6.125 | 155.58 | 4.00 | 101.60 | 10 |

| .9405 | 23.889 | |||||||||||||

| .945 | 24 | .9440 | 23.978 | .6969 | 17.701 | 1.000 | 25 | 10 | 254.00 | 6.125 | 155.58 | 4.00 | 101.60 | 10 |

| .9480 | 24.078 | |||||||||||||

| .969 | 24.61 | .9678 | 24.582 | .7208 | 18.308 | 1.000 | 25 | 10 | 254.00 | 6.125 | 155.58 | 4.00 | 101.60 | 12 |

| .9718 | 24.684 | |||||||||||||

| .984 | 25 | .9830 | 24.968 | .7363 | 18.702 | 1.000 | 25 | 10 | 254.00 | 6.125 | 155.58 | 4.00 | 101.60 | 12 |

| .9870 | 25.070 | |||||||||||||

| 1.000 | 25.40 | .9990 | 25.375 | .7520 | 19.101 | 1.000 | 25 | 10 | 254.00 | 6.125 | 155.58 | 4.00 | 101.60 | 12 |

| 1.0030 | 25.476 | |||||||||||||

| 1.063 | 26.99 | 1.0615 | 26.962 | .8145 | 20.688 | 1.000 | 25 | 10 | 254.00 | 6.125 | 155.58 | 4.00 | 101.60 | 12 |

| 1.0655 | 27.064 | |||||||||||||

| 1.125 | 28.57 | 1.1240 | 28.550 | .8770 | 22.276 | 1.000 | 25 | 10 | 254.00 | 6.125 | 155.58 | 4.00 | 101.60 | 12 |

| 1.1280 | 28.651 | |||||||||||||

| 1.188 | 30.16 | 1.1865 | 30.137 | .9395 | 23.863 | 1.000 | 25 | 10 | 254.00 | 6.125 | 155.58 | 4.00 | 101.60 | 12 |

| 1.1905 | 30.239 | |||||||||||||

| 1.250 | 31.75 | 1.2490 | 31.725 | .9390 | 23.851 | 1.000 | 25 | 10 | 254.00 | 6.125 | 155.58 | 4.00 | 101.60 | 14 |

| 1.2530 | 31.826 | |||||||||||||