Oil & Gas

The oil, gas, and energy industries comprise a wide array of market segments, each with a multitude of unique components. Yet they each share the same requirements; the need to increase the capacity of existing machines, to reduce cycle-times, to achieve minimal down-time, while maintaining quality and consistency.

Our ZX boring, facing, and contouring systems are Cogsdill’s major offering to these industries from our vast tooling portfolio.

Total control

under pressure

Zero backlash for ultimate precision

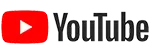

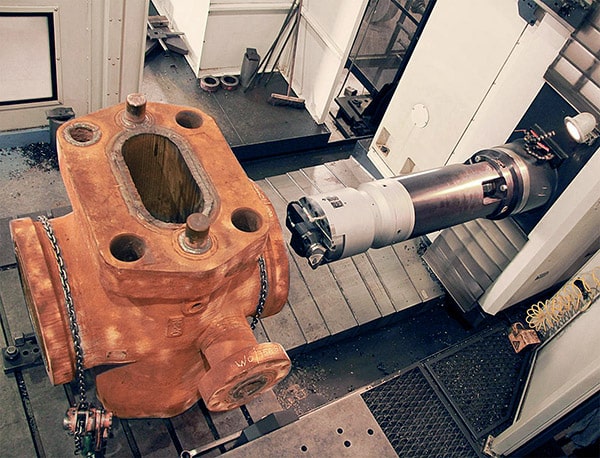

When you are faced with machining large heavy components time and time again, you need a tool system that is going to give you the ultimate in reliability and repeatability. ZX tools are not only designed to be strong, durable and consistent, but offer accuracy and quality to meet the stringent demands of the oil and gas industries.

Using our proven actuation mechanism, based on a “sliding inclined” wedge principle, our ZX tooling range ensures a backlash-free operation, even when working with the toughest materials.

Pushing the boundaries

Setting new standards

Because the oil and gas sector is facing new challenges.

As the worldwide demand for oil and gas grows, so does the task of manufacturing the required components. In order to keep up with global expectations, the oil and gas industry is being pushed to tap reserves in deeper, harsher and more remote locations – whether on land, offshore or subsea.

Extraction in hostile environments is becoming enormously challenging and complex. From arctic to desert temperatures, deep-sea pressures, as well as corrosive and abrasive elements, it is essential that the modern processing technology is safe, efficient and economical. To increase their durability and reliability, exotic and highly engineered materials are now being used within the components, such as inconel and super duplex. The equipment itself is getting larger and heavier whilst tolerances are getting tighter and surface finishes are becoming finer.

Working alongside world-leading oil and gas companies, Cogsdill is continually developing innovative solutions and pushing the boundaries of cutting-tool technology, to set new standards in manufacturing processes for key components

Our ZX facing, contouring and modular boring systems have become the global oil and gas industry’s preferred preference for secure and efficient production, with the latest advances in automation posed to reach new heights in optimised processes.

One modular system. Multiple machining operations.

Unlimited possibilities.

Cogsdill is proud to partner with leading global manufacturers of Christmas Trees, Wellhead Assemblies, Hydraulic Fracturing Pumps and other components – whether on land, offshore or subsea. From exploration to drilling, pumping and fracking, our clients all share the same requirements for proven precision tooling.

Many Cogsdill tool products are suitable for Oil and Gas, such as Shefcut reamers and Roll-a-Finish tools for sizing and finishing critical bores, Flipcut tools that perform back-spotfacing and chamfering operations on flange bolt holes, or Burraway tools that deburr front and back sides of holes in one pass.

Operations such as boring, taper boring, bottle boring/chamber boring, profiling, facing, overturning, backspot facing, internal contouring, grooving, threading and API ring grooving, are all achieved utilizing the modular ZX system.

The ZX tools are designed to use ISO inserts, giving them the flexibility for machining an assortment of materials with a simple insert change. They have enough stroke and strength to rough machine both pre-weld and post-clad, and given the wide capacity range of these tools, they can be used to machine both reclaimed and new components.

A selection of the countless components that utilize Cogsdill tooling:

- Blowout Preventers

(inc. Ram BOPs and Annular BOPs) - Valve Bodies & Blocks

(inc. Y-Blocks / L-Blocks / T-Blocks) - Master Valve Blocks (MVBs)

- Valves, Pumps, Connectors & Couplings

- Casing Spools, Heads & Hangers

- Tubing Heads & Hangers

- Christmas Trees

- Crosses & Tees

- Flanges (inc. Tubing Flanges)

- Chokes & Choke Valves

- Frac Trees & Heads (Goat’s Heads)

- Frac Pumps & Power Ends

- Mud Pumps & Fluid Ends

- Directional Drilling Components

(inc. Adjustable Bent Housing) - Drill String Connectors, Tubes & Pipes

- Drilling Spools

- Manifolds

Boring. Facing. Grooving.

The only solution for reliability and repeatability trusted by leading oil and gas manufacturers.

Ring Grooving

Subsea, Wellhead and Christmas Tree equipment have pressure energised ring seal gaskets, or more specifically ring grooves.

Generally, where two metallic surfaces meet, a closely dimensioned groove needs to be cut into the face of a pipe flange. Together with a gasket, a groove helps create a seal between the parts. The groove requires both a close tolerance and high-quality surface finish that must be free of indentations, score marks, tool and chatter marks.

This is even more critical in oil and gas components where there needs to be an absolute trust in the process security and confidence that the seal does not fail under extreme pressure and/or remote locations.

It is important, therefore, that the groove meets the design specifications set out by the industry-standard American Petroleum Institute (API) – including BX, R and RX styles – to cope with a range of high pressure and high-temperature scenarios, in order to be suitable for environments like deep-sea applications.

- ZX Facing & Contouring Heads for machining ring grooves in oil and gas components.

Product features:

- Cogsdill tools are designed to accept ISO standard inserts in order to provide the flexibility for machining varying materials with the same tool; from stainless and alloy steels through to difficult materials such as Inconel 718 and cladded Inconel 625.

- The zero-backlash capabilities of the ZX Facing & Contouring Heads ensure a consistent groove can be achieved.

- The ZX heads have been specifically designed to profile machine, as opposed to plunge, in order to create the tolerances and finer finishes required by the oil and gas industries.

- Due to the capacity of our heads, differing diameters can be achieved from one tool, allowing both roughing and finishing from one set-up.

Valve Seat Pockets

Valves are essential parts of any piping system and are widely used in the oil and gas industry to control the flow and pressure of contents – whether oil, gas, liquid or vapours – by opening, closing, or partially obstructing various passageways.

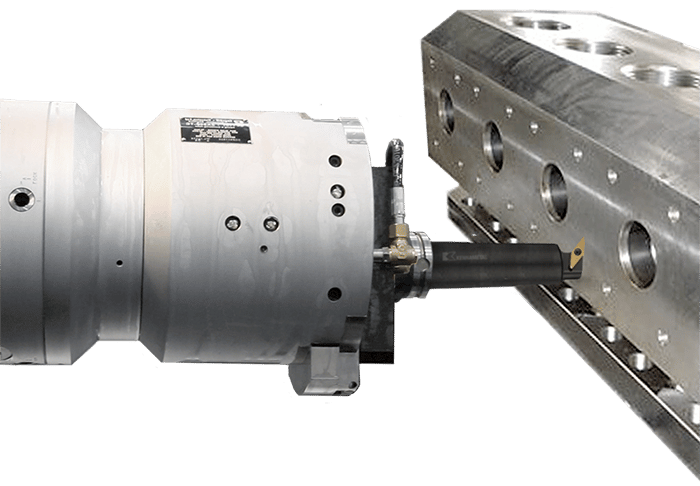

The valve seat pocket is a challenging feature to machine because of the narrow flow bore diameter, vibration tendencies, interrupted cuts, high tolerance and surface demands as well as long overhangs that require a tool with a stretched radial reach.

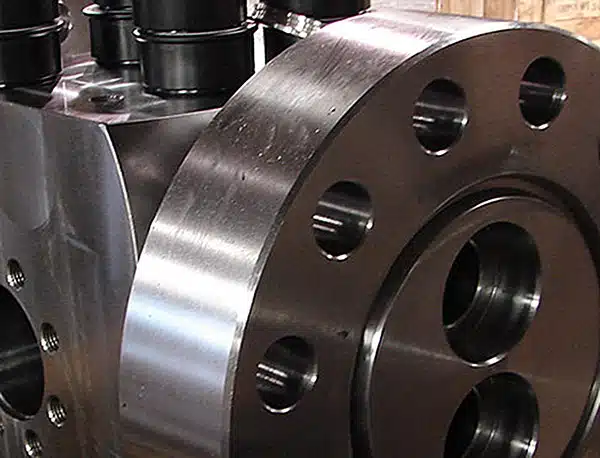

Extended and supported long-reaching ZX Modular Boring Tools called Valve Seat Pocket Tools are dedicated to machine cavities or different geometries inside deep bores. Valve Seat Pocket Tools feature an end cap mounted pilot shaft which feeds inside a collet pilot, mounted inside the bore for accurate support during machining operation.

ZX Valve Seat Pocket Tools have enough stroke and strength to rough-machine preclad seat pocket cavities and, using the same tool, to finish-machine the pocket in Inconel after cladding. Non-clad pockets can also be machined. Seat pocket tools are commonly used in steel, stainless steel, and Inconel. All tools feature 2:1 actuation ratio for easy programming.

- ZX MBT bottle-boring tool for machining seat pockets inside oil valve blocks.

Product features:

- In-bore piloting for rigid cutter support.

- Available in single and twin-slide designs to fit industry-standard flow bore sizes.

- Modular construction, in standard lengths: stub, medium, and long reach. (Non-threaded design allows for easy assembly and disassembly of modular sections.)

- Longest tool slide strokes available, for maximum diameter range.

- Internal through-tool coolant is standard.

- Fully enclosed actuation mechanism – no chip packing.

- A variety of insert cartridges are available, utilizing industry standard inserts.

Internal Profiling

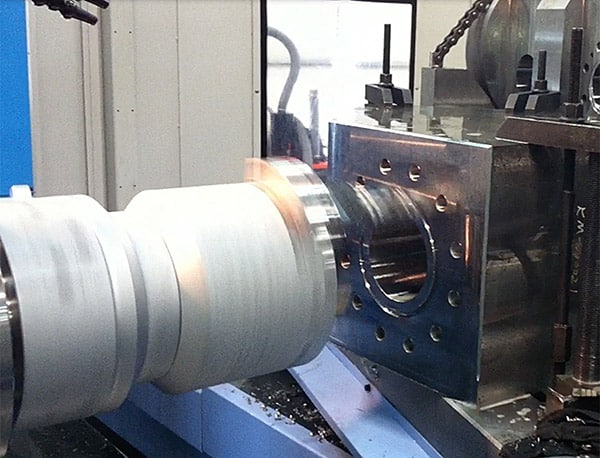

Many oil and gas components, such as fluid-ends on Fracking pumps, have cavities which encompass complex internal profiles and contours that need to be produced to exacting tolerances and fine surface finishes.

These components are manufactured from varying materials, such as stainless steel and super duplex, which can create a whole series of challenges from vibration tendencies, interrupted cuts and differing chip/swarf issues, especially when machining critical internal features.

The Cogsdill ZX Facing & Contouring Head, in conjunction with a simple two-axis CNC program – utilizing the W and Z axis on a Horizontal Boring Mill (HBM) – ensures confidence when producing contours, radii, tapers, chamfers and profiles. When combined with a generous radial stroke and through coolant as standard, the ZX System is an ideal solution for these components.

Backlash is eliminated due to Cogsdill’s unique internal mechanism, which can maintain your part-to-part repeatability and ensure continuous quality standards. In addition to cycle-time savings, the modular approach also minimises tooling costs by performing multiple operations from one set-up.

- ZX Facing & Contouring Heads for machining internal profiles and contours in oil and gas components.

Product features:

- The heads are designed to accept industry standard top-tooling and inserts.

- Though coolant as standard for greater chip evacuation.

- High material removal rates.

- Rigid and durable design.

- Large diameter range.