Universally speaking

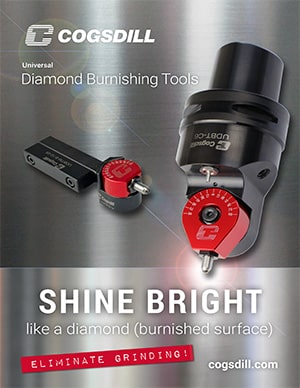

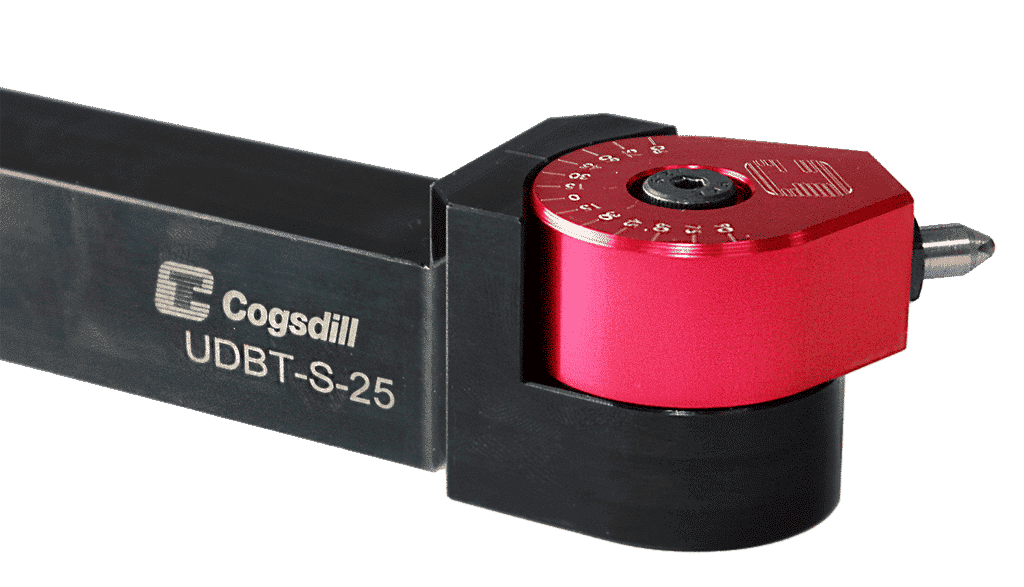

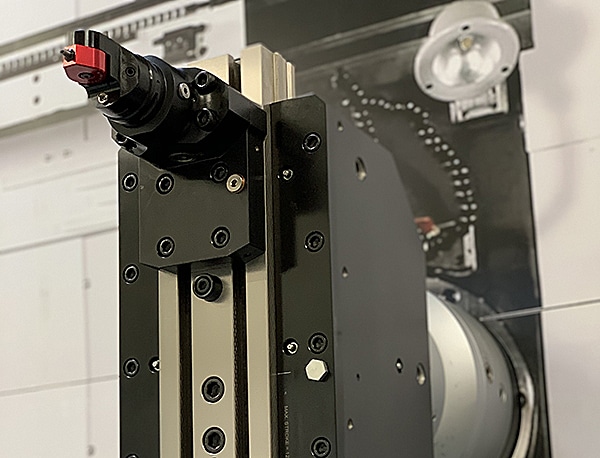

The latest addition to the Cogsdill Burnishing portfolio is the Universal Diamond Burnishing Tool (UDBT).

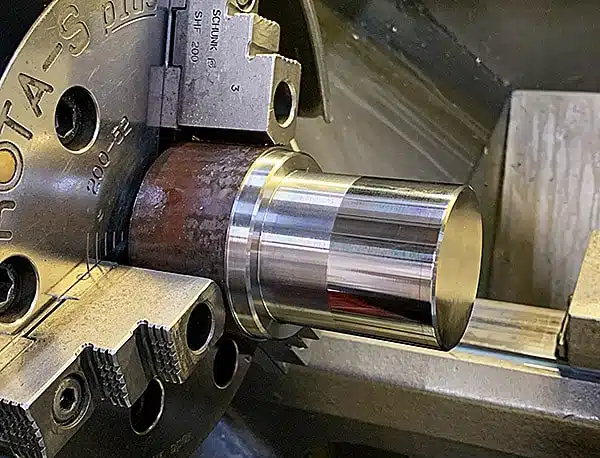

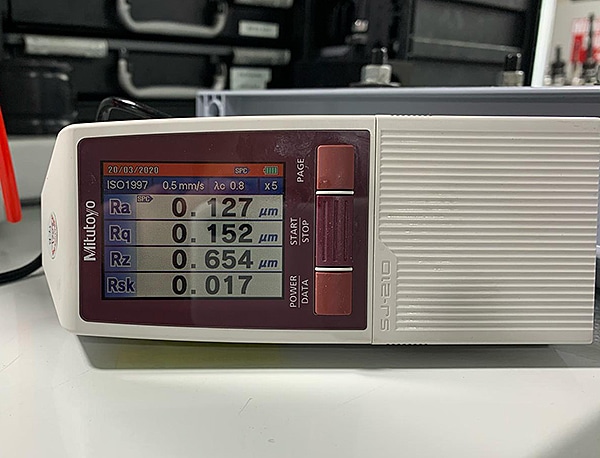

Using Cogsdill’s proven diamond insert geometry, our premium range of burnishing tools can achieve low RA surface finishes, by cold flowing the peaks into the valleys in one pass – achieving results not attainable from any other metal removal process.

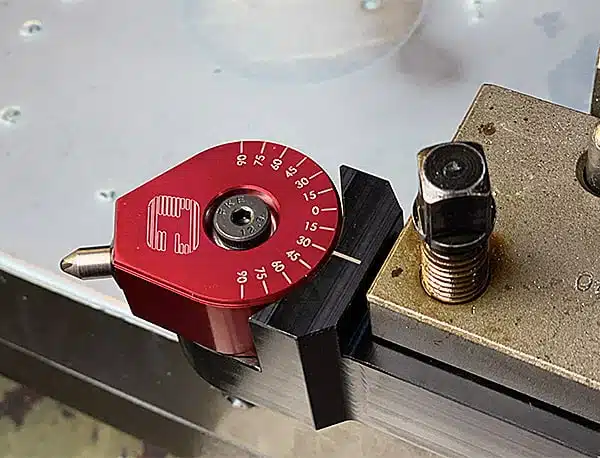

UDBT are designed to be adjustable through 180 degrees, which makes them the ideal choice tool for lower volume batch components where a designated orientated tool is not required.

The quick and simple castellated adjustment makes this the most versatile diamond burnishing tool on the market!

Simple and Efficient

Cogsdill Universal Diamond Burnishing Tools (UDBT) are designed to produce mirror-like finishes on any surface; from carbon steels to tool steels, cast iron to alloys, and most ferrous and non-ferrous metals.

UDBT offers the flexibility for burnishing large bores, outside diameters, tapers and faces to achieve superior surface finishes not achieved by turning alone.

Developed as a solution for burnishing low volume batch components, this single tool streamlines operations significantly as it can be utilized in either left or right-handed machine configurations – eliminating the need for multiple tools in specific environments.

Further more, set up and operation is relatively simple, no special operator skills are required.

As a result, Cogsdill UBDT offers incredible production efficiencies and cost effectiveness.

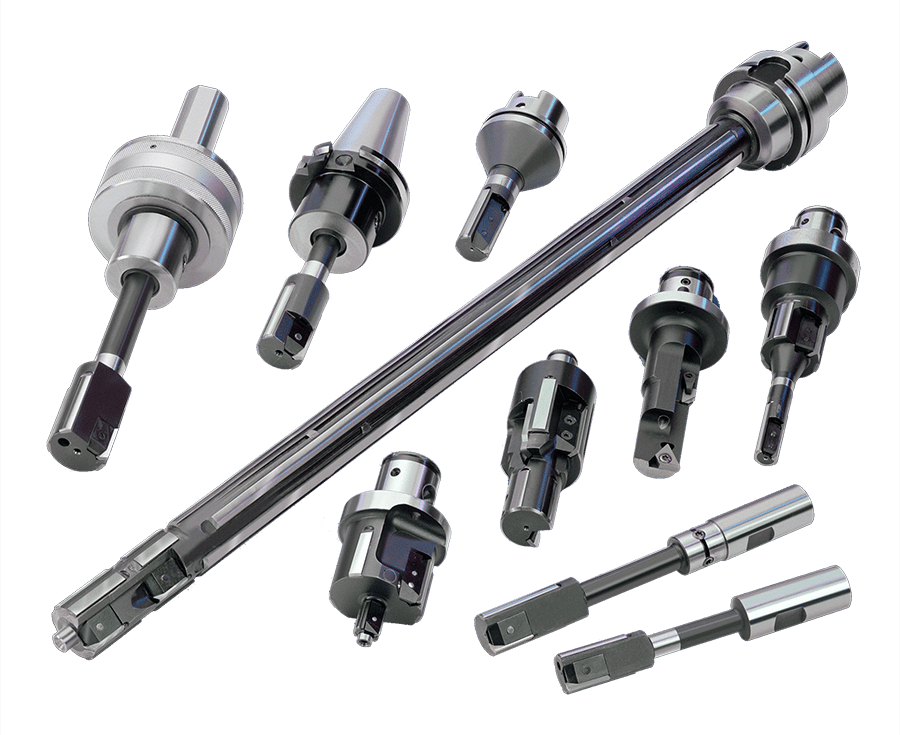

Standard model ranges available from stock:

- UDBT-S-25 (Straight Shank with 25mm square section)

- UDBT-S-0750 (Straight Shank with ¾ inch square section)

- UDBT-S-1.00 (Straight Shank with 1 inch square section)

- UDBT-C4 (Capto C4 Shank)

- UDBT-C5 (Capto C5 Shank)

- UDBT-C6 (Capto C6 Shank)

The Capto C4, C5 and C6 versions are supplied with through coolant capability but whilst the tool must be used with coolant, no special coolant is required. Straight oils, soluble oils, and synthetic coolants can be used to provide the necessary lubrication.

Other shanks available upon request:

- KM50 and KM63 – integrated KM with through coolant capability.

How Universal Diamond Burnishing Tools work:

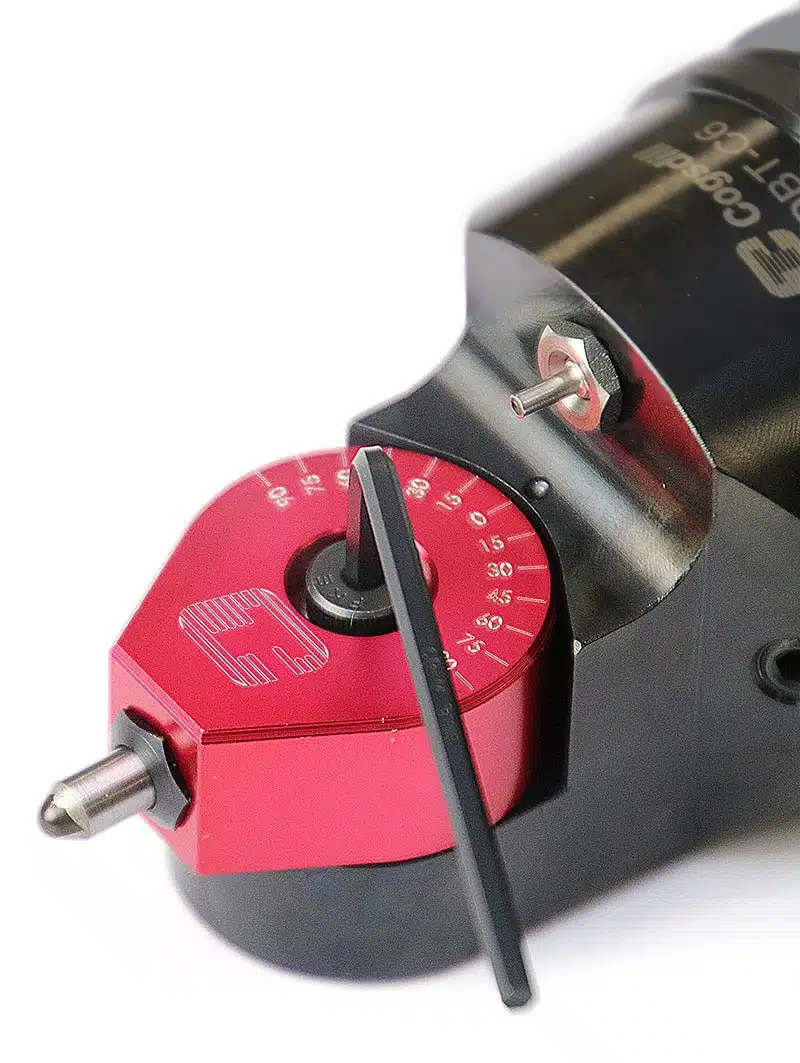

| 1 | Undo the retaining cap head with a hex wrench which will release the castellated housing from its locked position. |

| 2 | Rotate the housing to the required angle and then tighten the retaining cap head to secure the tool. |

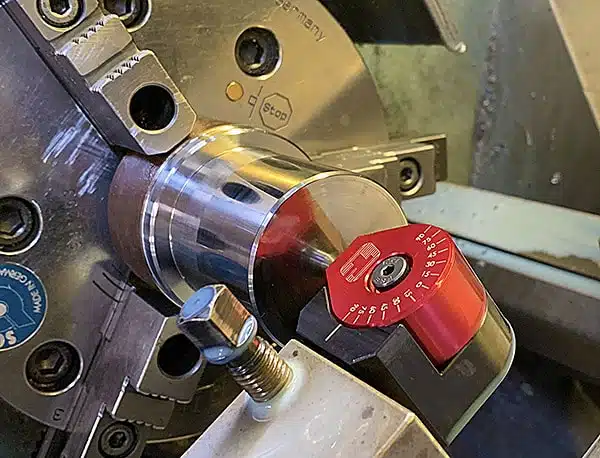

| 3 | The UDBT is then mounted in the tool post or turret of the desired machine. |

| 4 | The diamond burnishing nib is brought into contact with the workpiece at the centerline of the part and against the surface being finished. |

| 5 | The tool is then fed into the workpiece an additional .002 or .003 inch (.05 or .08mm) to allow the diamond insert to become disengaged from the stop in the holder. |

| 6 | The spring, with its preload, forces the diamond against the workpiece. |

| 7 | The tool is then fed along the surface of the rotating workpiece to produce a mirror-like finish. |

One Tool. Multiple Applications.

Designed for ultimate versatility within low volume productions.

A standard range of tools are available.

Please contact us for delivery.

Standard Tool Specifications

UDBT-S-25

UDBT-C5

UDBT-C6

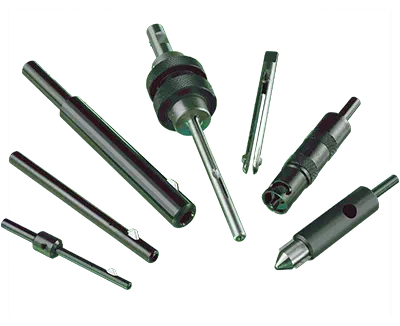

Replaceable Diamond nibs

The Diamond nibs are easily replaced once they have worn.

| 1 | Simply undo the retaining nib holder with a wrench, and remove the nib from the holder. |

| 2 | Make sure that that tool body and holder are clean. |

| 3 | Replace the o’rings on the nib, insert the nib into the holder and screw back into the tool body. |

| 4 | Re-tighten the retaining nib holder with a wrench. |

Nib Specifications