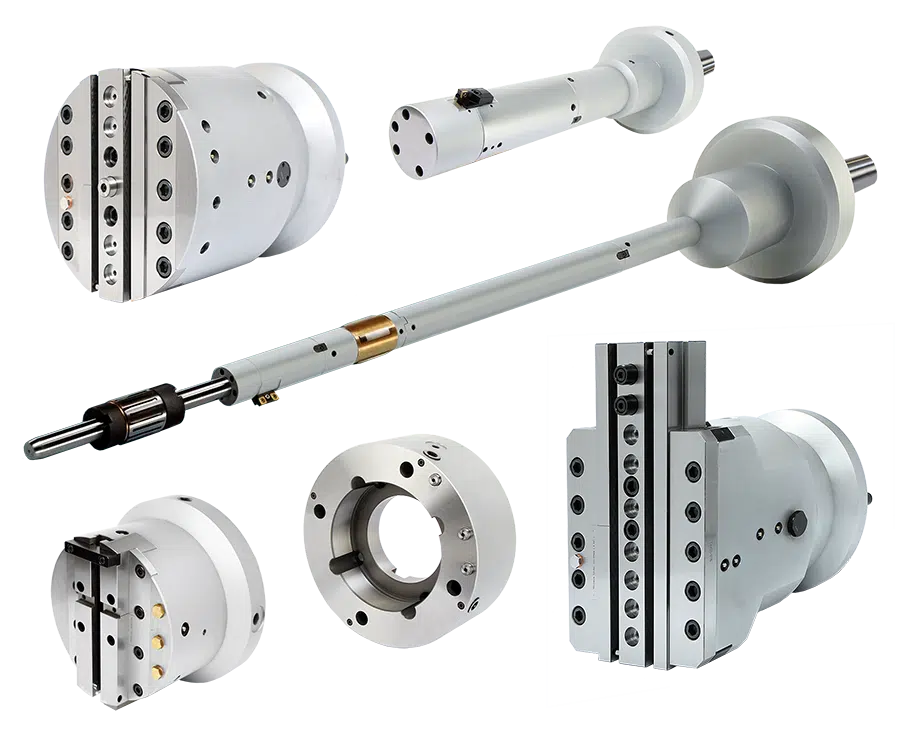

Our Product Range

Cogsdill has offered a wide array of precision tools for the metalworking industry since 1914 – and here you will discover a selection of our current tools and ranges. With over 95% of our standard range products now available off-the shelf and ready for immediate shipping, we’re confident to keep you operational.

We also provide custom tools for various markets.

Whatever your needs, wherever you are in the world, we are happy to help assist you with your manufacturing requirements and deliver a bespoke tool that fits your exact requirements. Our lead times for even the most complex tools will astound you – and we will guide you through the process step-by-step. Most of our customers are surprized that we are able to solve the unsolvable.

Then again, we’ve been doing that for the last century.

We also provide custom tools and tooling machines for various markets.

Whatever your needs, wherever you are in the world, we are happy to help assist you with your manufacturing requirements and deliver a special tool that fits your exact requirements. Our lead times for even the most complex tools will astound you – and we will guide you through the process step-by-step. Most of our customers are surprised that we are able to solve the unsolvable.

Then again, we’ve been doing that for the last century.

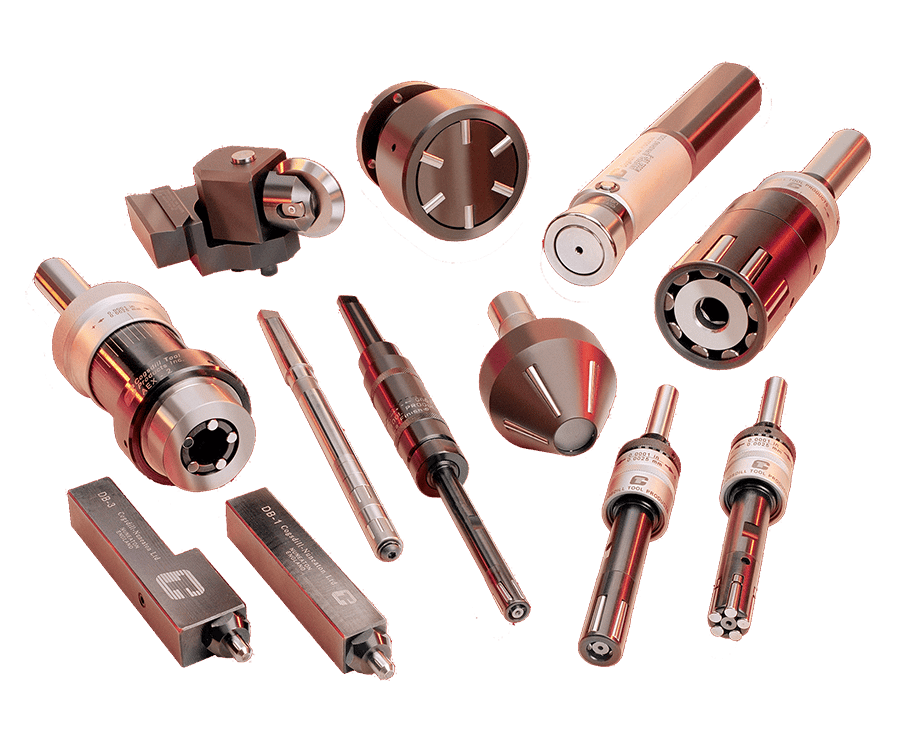

Burnishing Tools

Cogsdill Roll-a-Finish tools offer you a fast, clean, and economical method of sizing, finishing and work hardening metal parts to exacting specifications. The tools can be operated on any spindle. Parts of virtually any configuration and material are accurately sized within “tenths,” with surface finishes as fine as 2 micro-inches (0.05 micrometers)… in seconds!

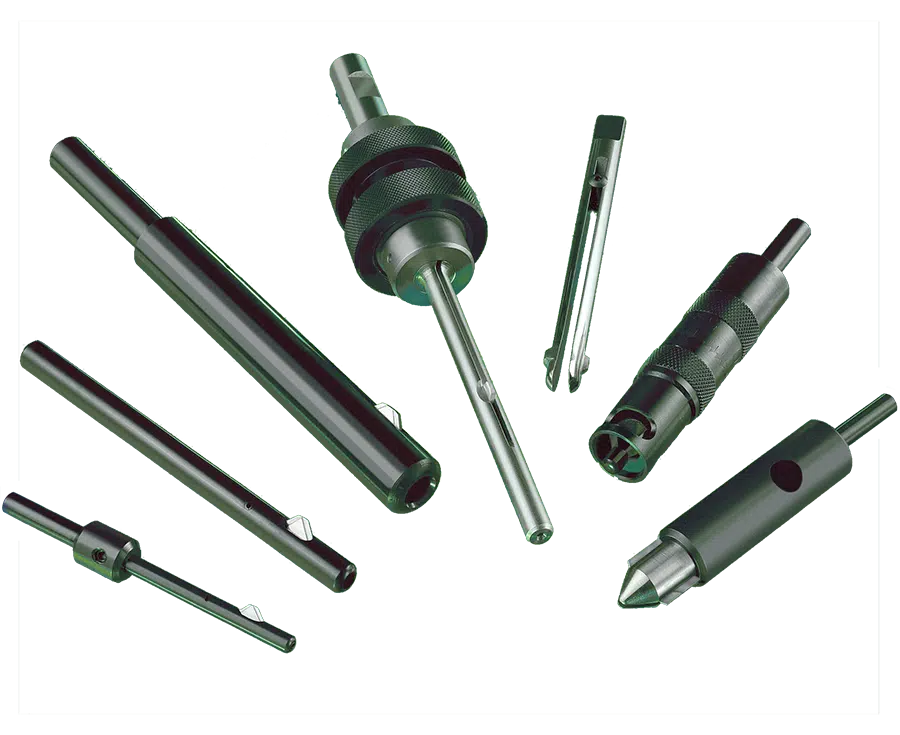

Deburring Tools

Deburring holes is usually a costly and time-consuming operation. The back sides of holes are particularly difficult, as they are frequently inaccessible with conventional deburring tools. Cogsdill offers you a better way to get rid of those troublesome burrs. Burraway and Burr-Off mechanical hole-deburring tools remove burrs on the front, back, or both sides of drilled holes in one pass – fast, easy, and economical solutions for your hole-deburring problems.

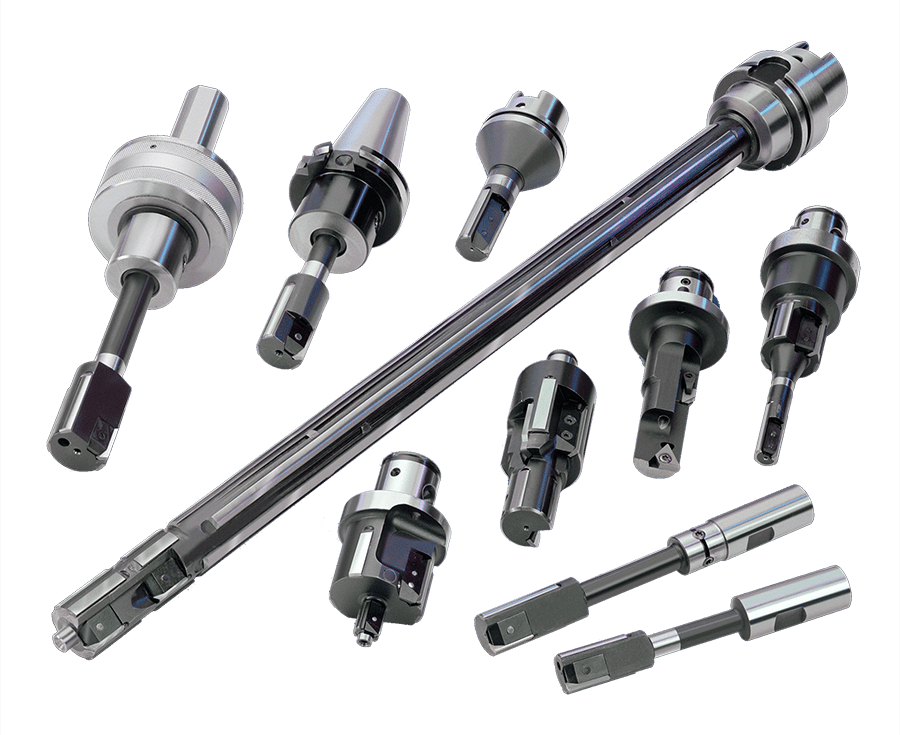

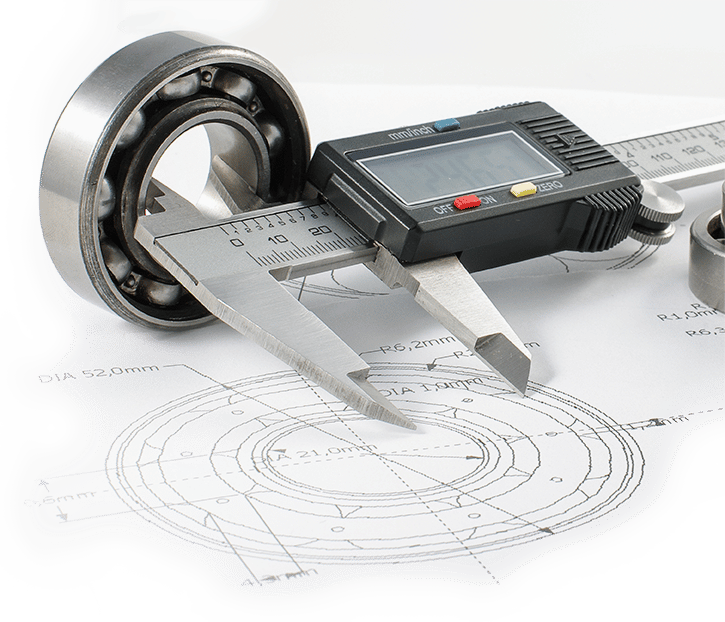

Shefcut Reaming

Shefcut precision reamers and boring tools are designed to produce accurately sized, extremely straight and round bores with fine surface finishes. Multiple guide pads rigidly support a single, replaceable cutting blade for exceptional stability and alignment. Size control, surface finish quality, and hole geometry are superior, compared to results from conventional reamers and boring tools. Each tool is designed for a specific cut diameter. Standard and custom tool designs are offered. Also available from Cogsdill: tool holders designed to complement and enhance the performance of Shefcut tools, and Shefcut setting fixtures for fast and accurate tool settings.

Recessing Tools

Precision grooving, recessing, internal and external facing and chamfering; widest array of standard tooling, broadest range of solutions! Standard recessing heads from stock for most grooving applications and machines, including AR Series and Nobur deep-bore recessing. Cutters and pilots designed for the recessing application. Related products: generating heads, for performing multiple operations (facing, recessing, boring, chamfering, contouring) at one spindle location; precision chamfering and back-chamfering tools.

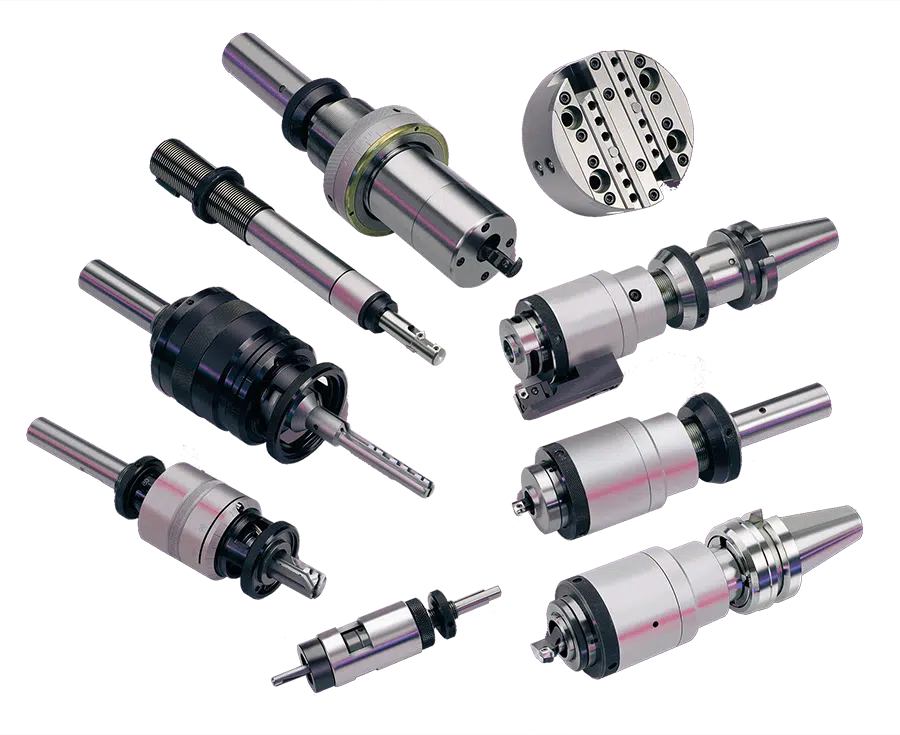

ZX Systems

Perform multiple operations on large parts, in one set-up or a minimum number of tool changes, with the ZX System. Boring, counter boring, facing, contouring, taper boring, deep-cavity boring, grooving, O.D. turning, threading, radius forming, back-spotfacing, chamfering, recessing, bottle-boring operations, on horizontal boring mills with programmable inner quill, or special purpose machines. Rigid, piloted cutter support for valve seat pockets, other extended reach applications. Greater accuracies, low set-up time, high machining rates, maximum productivity, lower costs.