Oil company invests in automation

US manufacturer looks to UK innovation to drive throughput efficiency in midst of oil sector downturn and prepare them for Industry 4.0

As engineering evolves, manufacturing companies are looking to stay ahead of the curve by re-evaluating capital expenses and workflows to remain competitive and maintain margins. True automation of Industry 4.0 promises solutions that will curb what are considered today’s most expensive line-items – Manpower and Machine Downtime. One such US company selected a proven partnership to ensure its success far into the future.

This major Texas-based oil company reached out to two of their vendors, who have worked closely for decades – Doosan and Cogsdill – with a specific request; develop a process for auto-loading facing heads, boring tools and splining tools, onto a conventional HBM for machining their components.

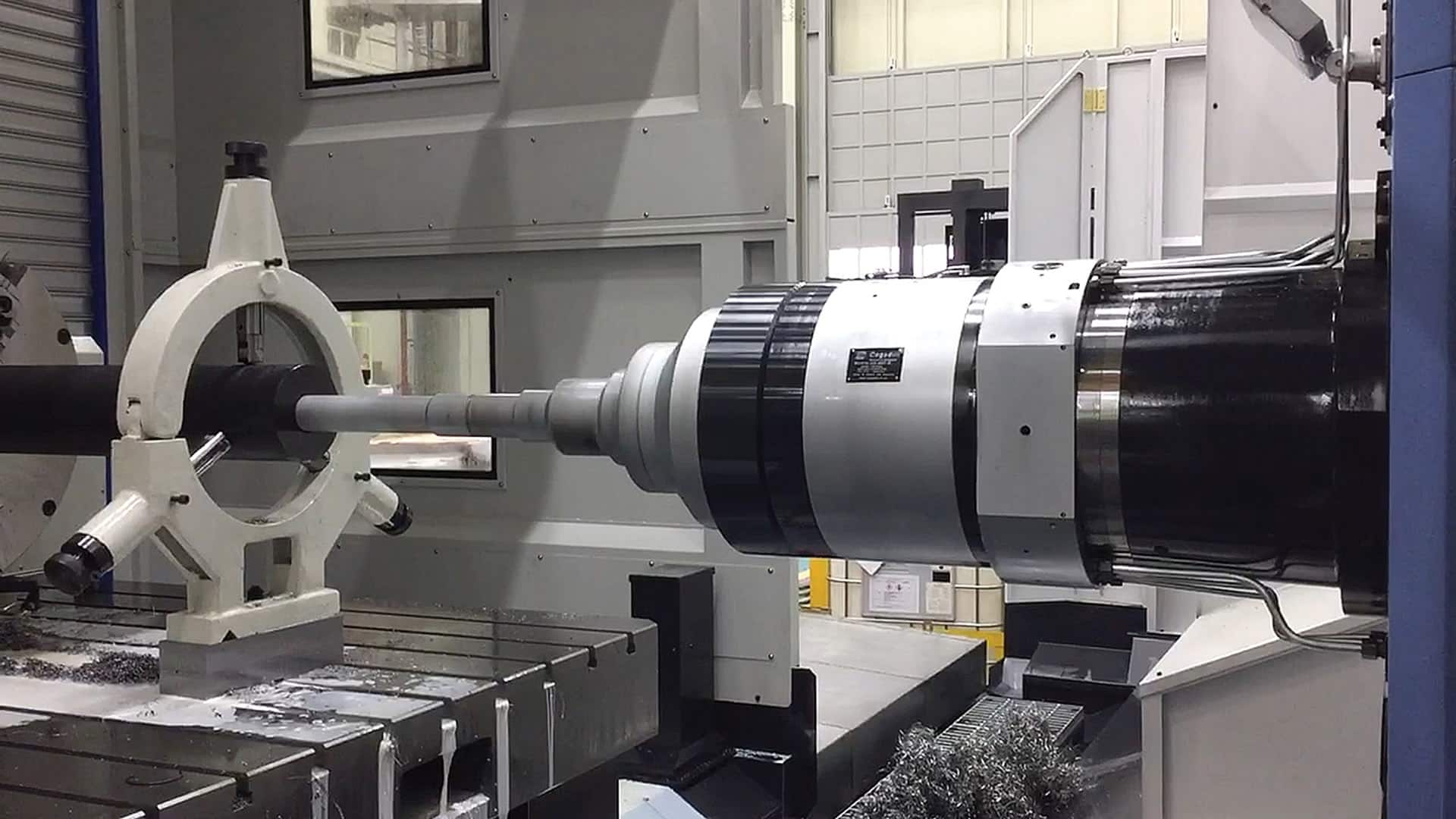

Having delivered solid results and support for the oil company’s Dubai and Russian facilities, there was an insistence for Cogsdill’s ZX modular tooling systems in their flagship manufacturing headquarters in Houston. Despite the downturn in oil prices, they believed this new future-proofing technology was crucial to their process and investment.

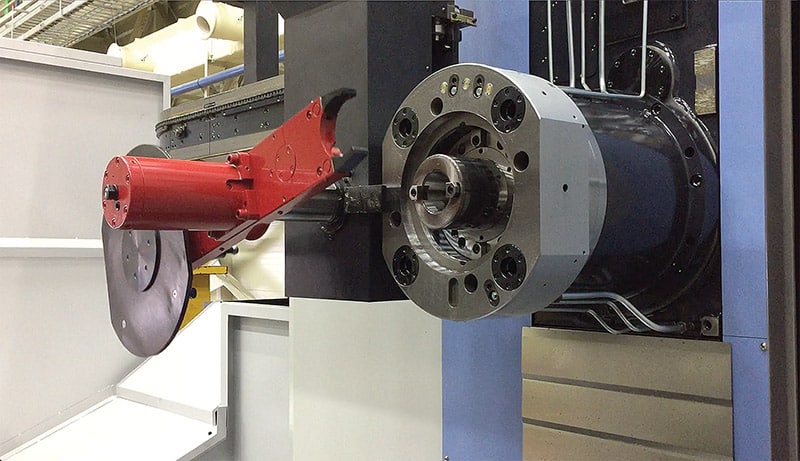

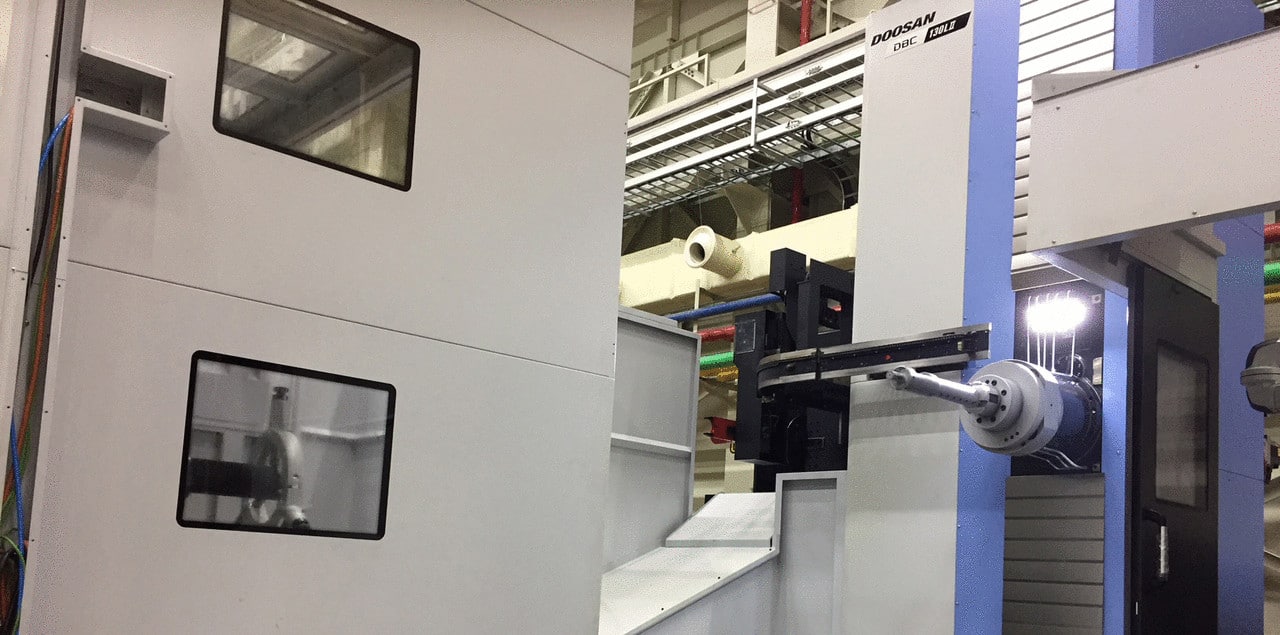

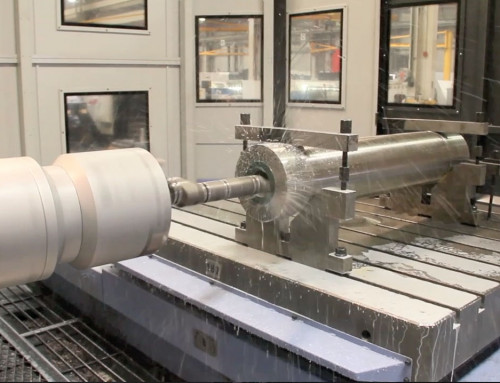

Forward-thinking allowed engineers from Korea and UK to design and manufacture an auto-coupler system that enabled the facing heads and other tooling to be automatically loaded from a tool stacker mounted to the Doosan DBC130 Horizontal Boring Mill. While auto tool-changing is certainly nothing new, manipulating tools and couplings weighing in excess of 500kg presents its own set of challenges.

The innovative adaptation of a standard spindle, to incorporate a spindle interface with a hydraulically-actuated clamping system, allows the tools to change automatically. Enabling both rotating and non-rotating tools, the adaptor allows for interchangeability between internal contours, bottle bores and splining features as opposed to requiring multiple operations on several stand-alone machines. Thus, providing far greater capacity and drastically reducing the manual intervention usually associated with manufacturing these types of components.

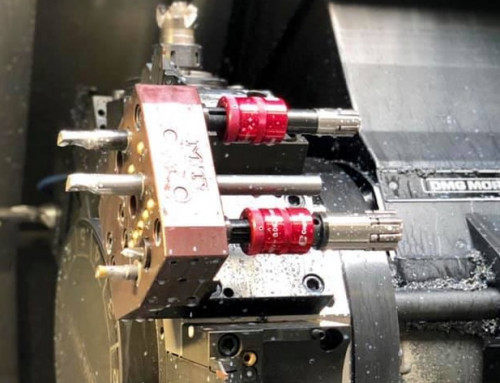

Furthermore, the new process and product innovation enables vast capabilities at speed and scale, along with the added benefit of high-pressure coolant for evacuating the swarf, something that cannot be efficiently achieved with conventional tooling. Together, this new hands-off approach is a major turning-point for the next-wave of fully autonomous production.

Working alongside Doosan’s exclusive UK agents, Mills CNC set a foundation of trust that led to this project’s success. “This is a fantastic collaboration with Doosan – a partner that we have a great relationship with”, Cogsdill’s UK Executive Director, Lee Donaldson, shared. “We’re continually evolving to best face engineering challenges and move towards the next phase of efficient automation – whether it be manufacturing materials and processes, or laser enhanced tools for auto-sizing.”

UK-based Tony Dale, Technical Director from Mills CNC saw the machine on display at DIMF in Korea. “The new range of DBC machines are impressive and this ZX auto-tool interface is a real game changer and cements Doosan’s global leadership when it comes to visionary heavy tool automation… and puts the HBM into a market position usually only associated with RAM-type machines.”

Perhaps the future of manufacturing may not yet be fully visualised, but the collaborative use of industrial know-how and attention to detail seems to be exactly what will guide Industry towards 4.0 – and ensure the UK is seen as the key innovation powerhouse within global manufacturing.

As first appeared in MTD and their MACH 2018 Brochure

Leave A Comment