The right tools for the job

Precision tooling specialist Cogsdill has been selected by Shrewsbury-based Sentinel Manufacturing to supply a package of Shefcut tools for producing tight tolerance features on a variety of components.

Designed and manufactured at Cogsdill’s facility in Nuneaton, the tools were designed rough the customer’s part, and include multi-diameter, pad guided fine boring and overturning tools.

Making the tools multi diameter ensures the concentricity between features is well within the customer drawing tolerance, while the pads rigidly support the single replaceable cutting blade, ensuring that size, surface finish quality, parallelism and roundness are also held to very tight tolerances.

Sentinel’s history stretches back to the 19th century hen Irishman Stephen Alley and his Scottish partner John Alexander MacLellan opened the Sentinel Engineering Works in Polmadie, Glasgow, producing a range of valves for industrial users in 1875.

Today, the business offers its customers an all-encompassing product lifecycle solution through a service through a service portfolio that includes CNC machining, assembly and product design and development.

Shefcut precise reamers and boring tools are a marked step-up from conventional tools ad designed to product accurately-sized, extremely straight and round bores with fine surface finishes.

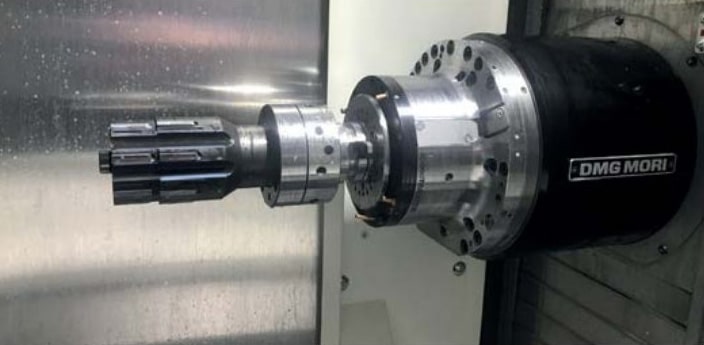

Multi-diameter fine boring tool

The system comprises a single, replaceable cutting blade which is supported by guide pads during the cut offering exceptional stability, alignment, size control, surface finish quality and hole geometry by effectively the cutting, guiding and supporting functions of the tool. And because the cutting blade is independent of the tool body it can be micro-adjusted over a limited range.

The tools are not confirmed to internal boring as they can be used on external diameters in process known as overturning. Think of this process as ‘external’ reaming with the same levels of accuracy, precision and geometry. Available in standard and custom formats, each tool is designed for a specific cut diameter.

This article originally appeared in Production Engineering Solutions in March 2021.

Leave A Comment